Continuous impurity removal system for lithium ion battery slurry

A technology of lithium-ion batteries and ion batteries, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems affecting the removal efficiency of the impurity removal system, the production efficiency of lithium-ion batteries, and large labor costs, etc., to achieve Improve preparation efficiency, achieve self-cleaning, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

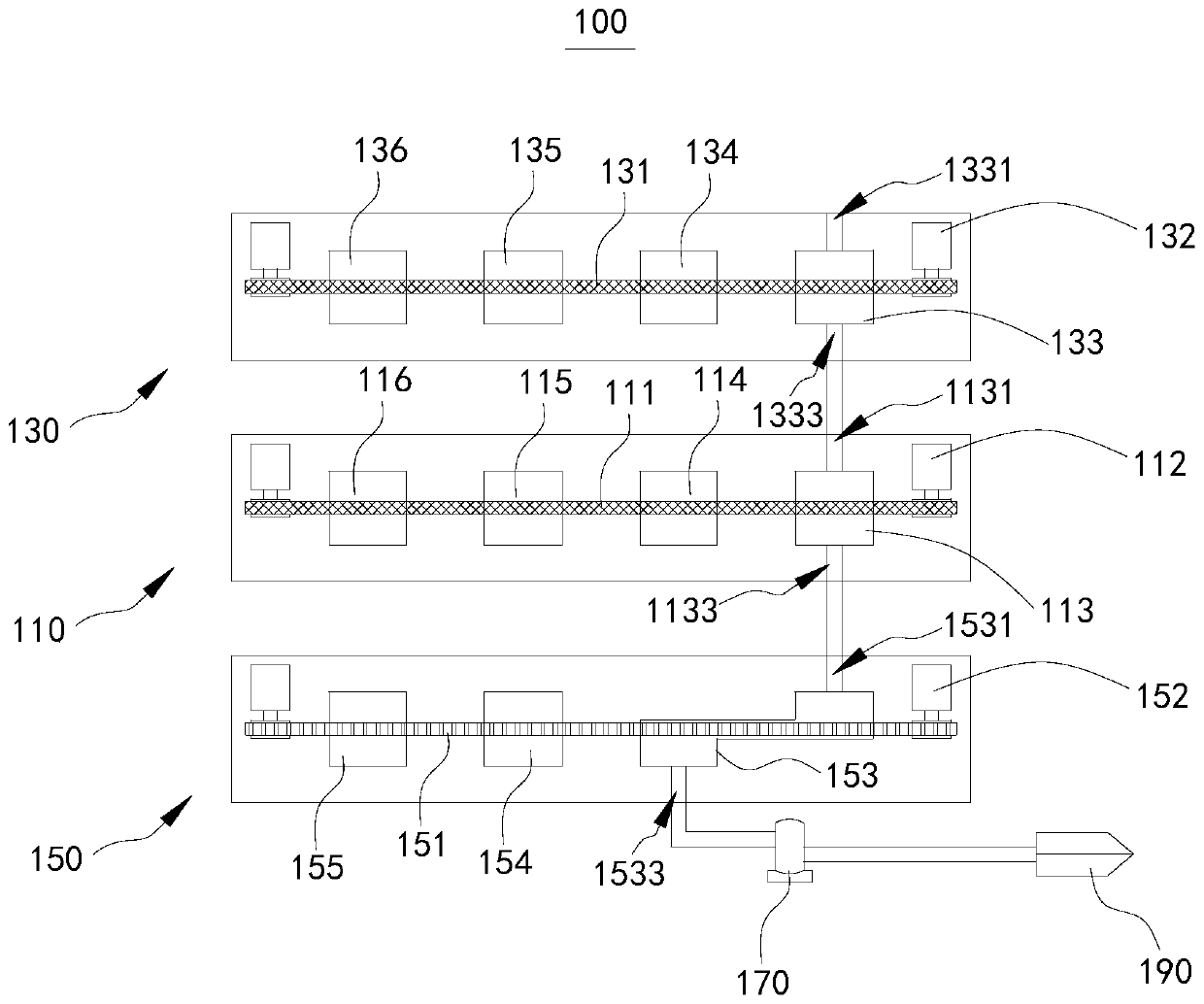

[0031] Please refer to figure 1 As shown, the lithium-ion battery slurry continuous impurity removal system 100 provided in this embodiment is used to remove impurities from the lithium-ion battery slurry during the lithium-ion battery preparation process. The lithium-ion battery slurry continuous impurity removal system 100 realizes The continuous impurity removal of lithium-ion battery slurry is improved, the production efficiency of lithium-ion batteries is improved, and self-cleaning in the continuous impurity removal process is realized, which greatly reduces labor costs.

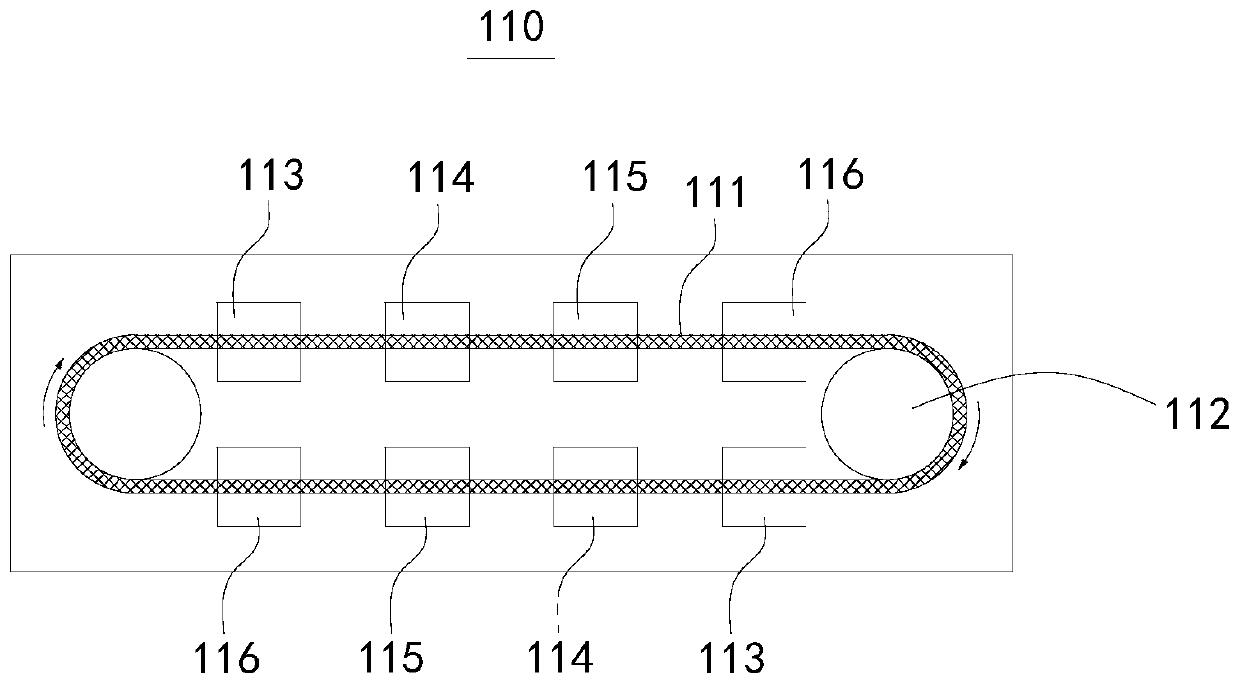

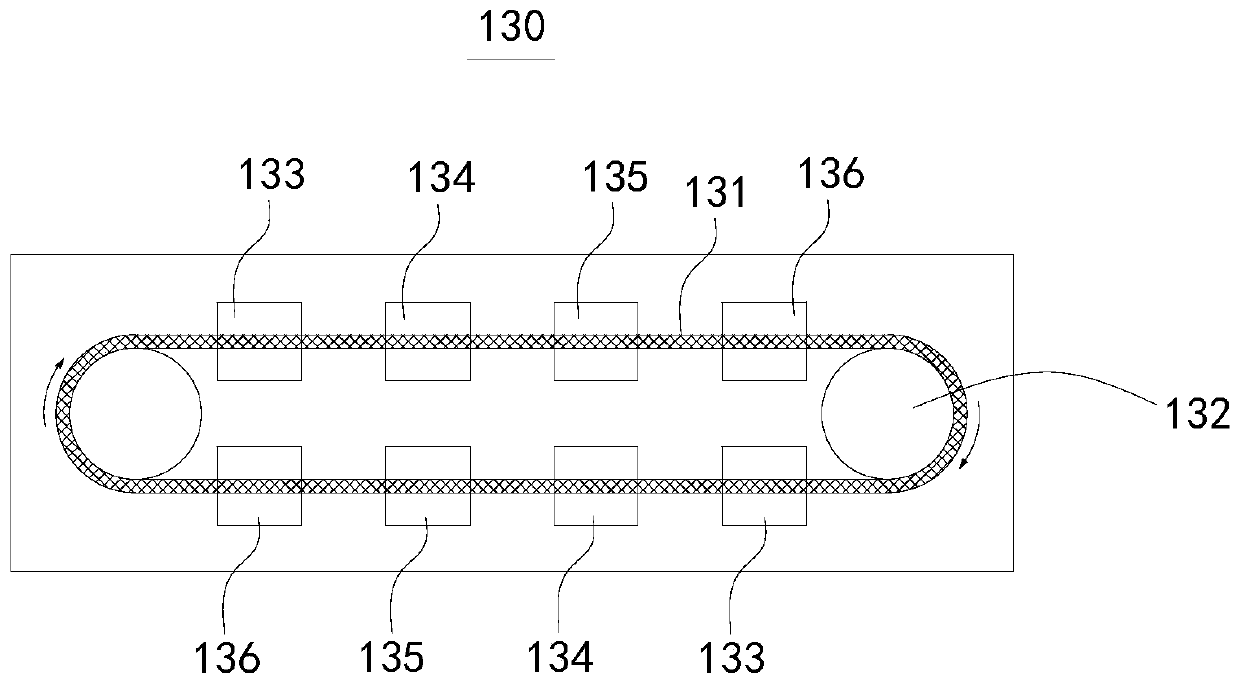

[0032]The lithium-ion battery slurry continuous impurity removal system 100 provided in this embodiment includes a first filter system 110, a second filter system 130, an iron removal system 150, a slurry pump 170, and a coating head 190. The output of the second filter system 130 is The feed end is connected with the feed end of the first filter system 110, and the discharge end of the first filter sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com