TBM hob abrasion detection device

A detection device and hob technology, which is applied in the direction of measuring device, optical device, material analysis through optical means, etc., can solve the problem of not being able to track and monitor the working condition of a single hob, increasing the difficulty and cost of manufacturing, and single knives Damage and other problems, to achieve the effect of eliminating the problem of optical path conduction, realizing miniaturization and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in combination with specific embodiments.

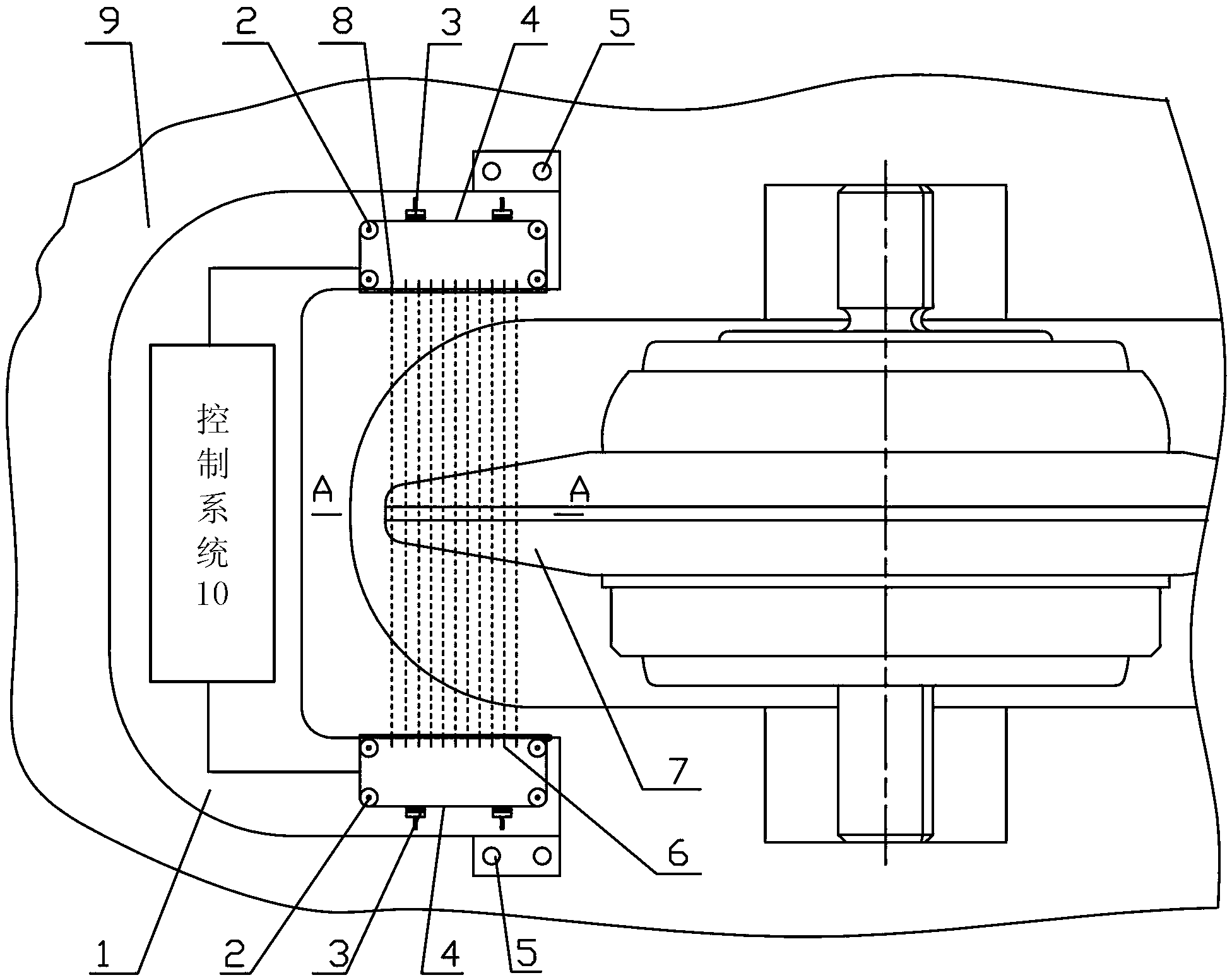

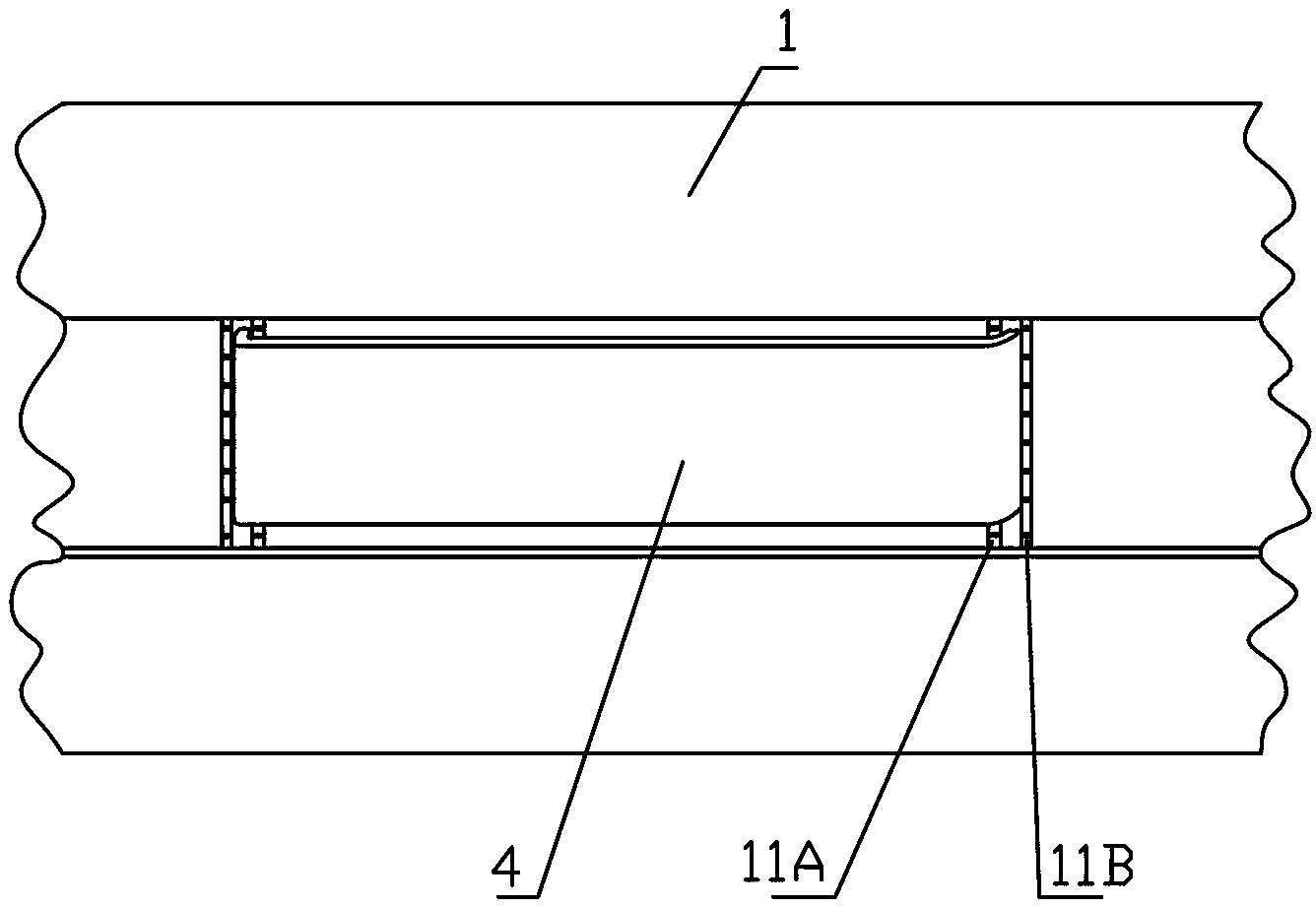

[0012] Such as figure 1 As shown, a TBM hob wear detection device of the present invention includes a concave-shaped housing 1 with screw holes, and is fixed on the TBM cutterhead 9 by screws 5 . The material of the side wall of the inner recess of the concave-shaped housing 1 (that is, close to the hob cutter ring 7) is a light-transmitting material, and one end of the side wall of the inner recess of the concave-shaped housing 1 is an optical signal transmitting end. The other end of the sidewall of the inner recess of the glyph housing 1 is an optical signal receiving end, and the optical signal transmitting end is provided with a laser emitter 6 that can emit a group of parallel laser beams, and the laser emitter 6 can emit a certain intensity The laser emitter 6 is vertically arranged inside one end of the concave-shaped housing 1 (that is, the optical signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com