Spherical support girder turning mechanism for open-type hard-rock boring machines

A technology for hard rock roadheaders and main beams, which can be used in mining equipment, earthwork drilling, tunnels, etc., and can solve problems such as inflexible steering and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

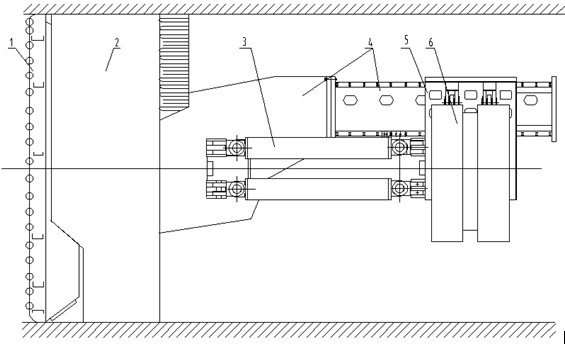

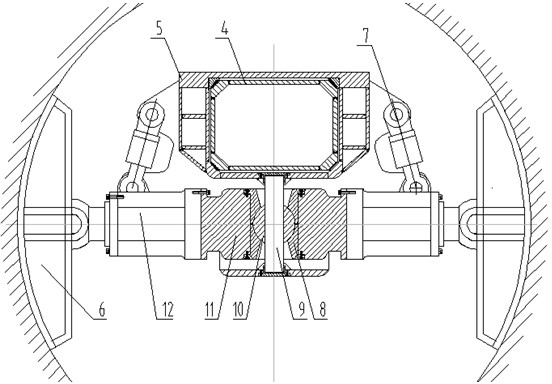

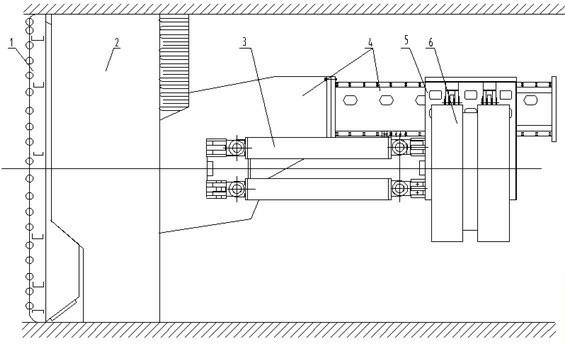

[0010] With reference to the accompanying drawings, an open-type hard rock roadheader spherically supported main beam steering mechanism is composed of a cutter head 1, a shield 2, a propulsion cylinder 3, a main beam 4, a saddle frame 5, a shoe 6, a torque cylinder 7, and a hinge joint The ball gland 8, the center pin 9, the hinge ball 10, the center block 11, and the horizontal support cylinder 12 are composed of the cutter head 1, the shield 2 and the main beam 4 of the full-section hard rock tunnel boring machine. The beam 4 and the saddle frame 5 are assembled together through a box-shaped structure with guide slides. 45° guide slideway, the saddle frame 5 and the horizontal support cylinder 12 are connected by 4 torque cylinders 7 on both sides, and a hinge ball 10 is provided at the position of the center block 11, and the hinge ball 10 is positioned by the hinge ball gland 8 Inside the center block 11, the center pin shaft 9 is loaded into the hinge ball 10 and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com