Miniature TBM (Tunnel Boring Machine) excavation system for tunnel excavation in physical simulation test

A physical simulation and micro technology, applied in the field of geotechnical engineering, can solve problems such as inability to accurately simulate and manual excavation, and achieve the effect of improving the accuracy of excavation simulation, improving excavation efficiency and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

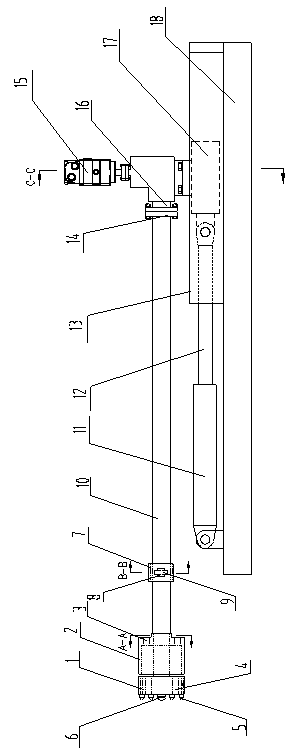

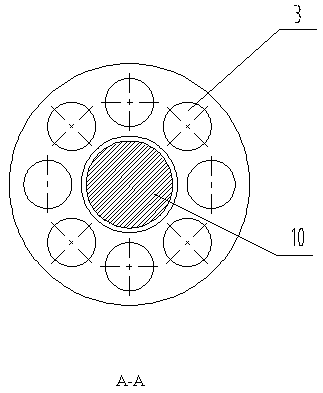

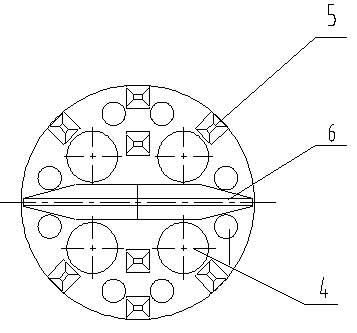

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] see Attachment.

[0028] A miniature TBM excavation system for physical simulation test tunnel excavation, the miniature TBM excavation system consists of a cutter head 1, a shield 2, a shoe 7, a transmission shaft 10, a tension jack 11, a guide rail 13, a motor 15, The base 17 is composed of a support stand 18. The support stand 18 is symmetrically provided with guide rails 13 along the length direction. The base 17 is movable on the guide rail 13. One end of the tension jack 11 is fixedly connected to the support stand 18 side The end of the piston 12 of the tension jack 11 is fixedly connected to the base 17, the axis of the tension jack 11 is parallel to the guide rail 13, and is located on the center line of the support stand 18, the tension jack 11 is externally connected to the hydraulic control device, and the motor 15 is fixedly installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com