Digging method for preventing strong or strong rock burst on active face

A tunnel face and rockburst technology, which is applied in the field of excavation with strong or extremely strong rockburst prevention and control, to ensure personal safety, ensure construction progress, and improve the ability to resist rockburst impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Excavation method for extremely strong rockburst prevention and control on the face, characterized in that the specific steps include,

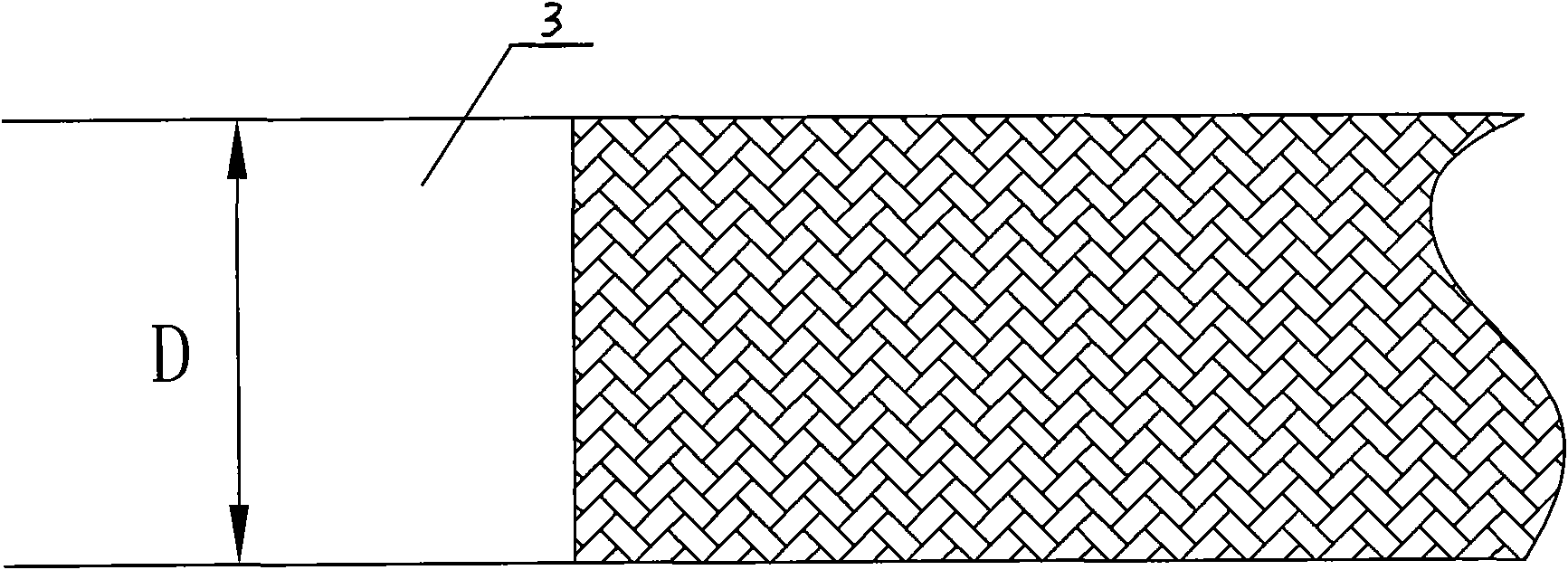

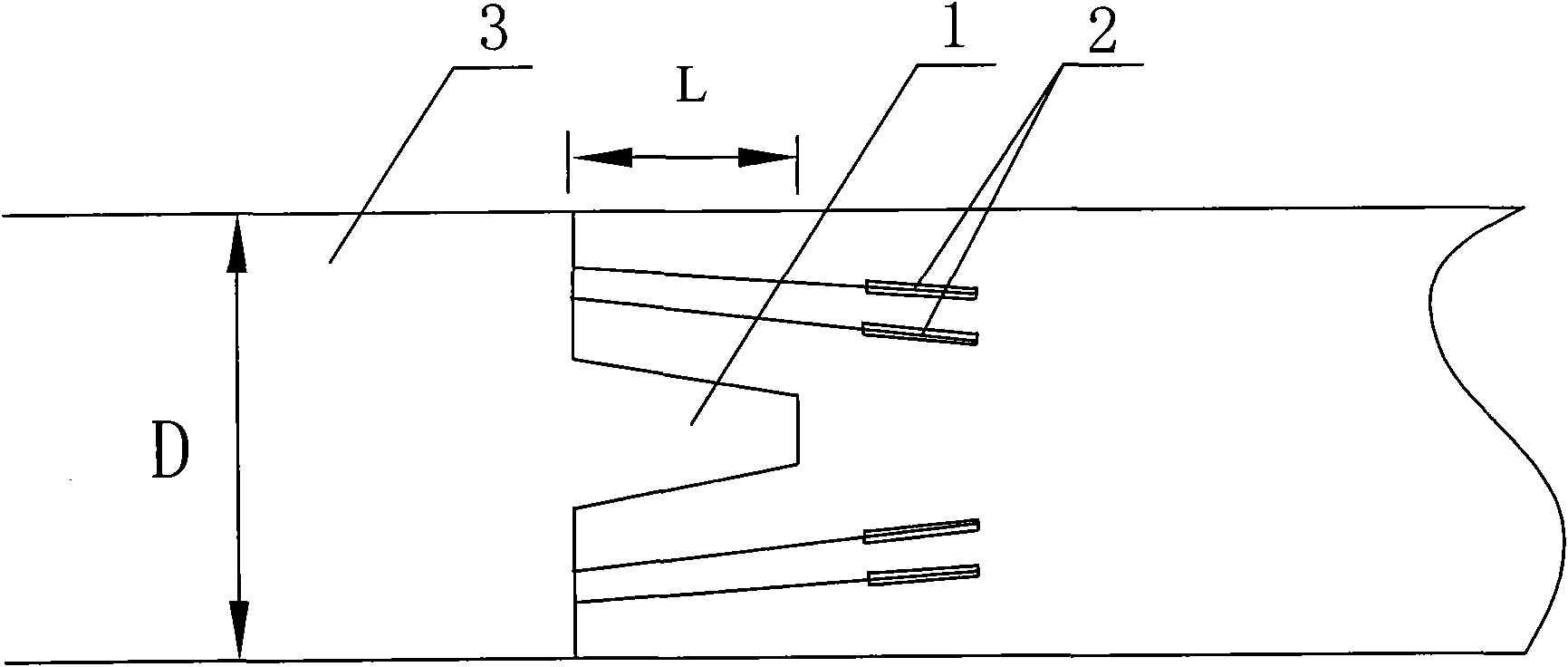

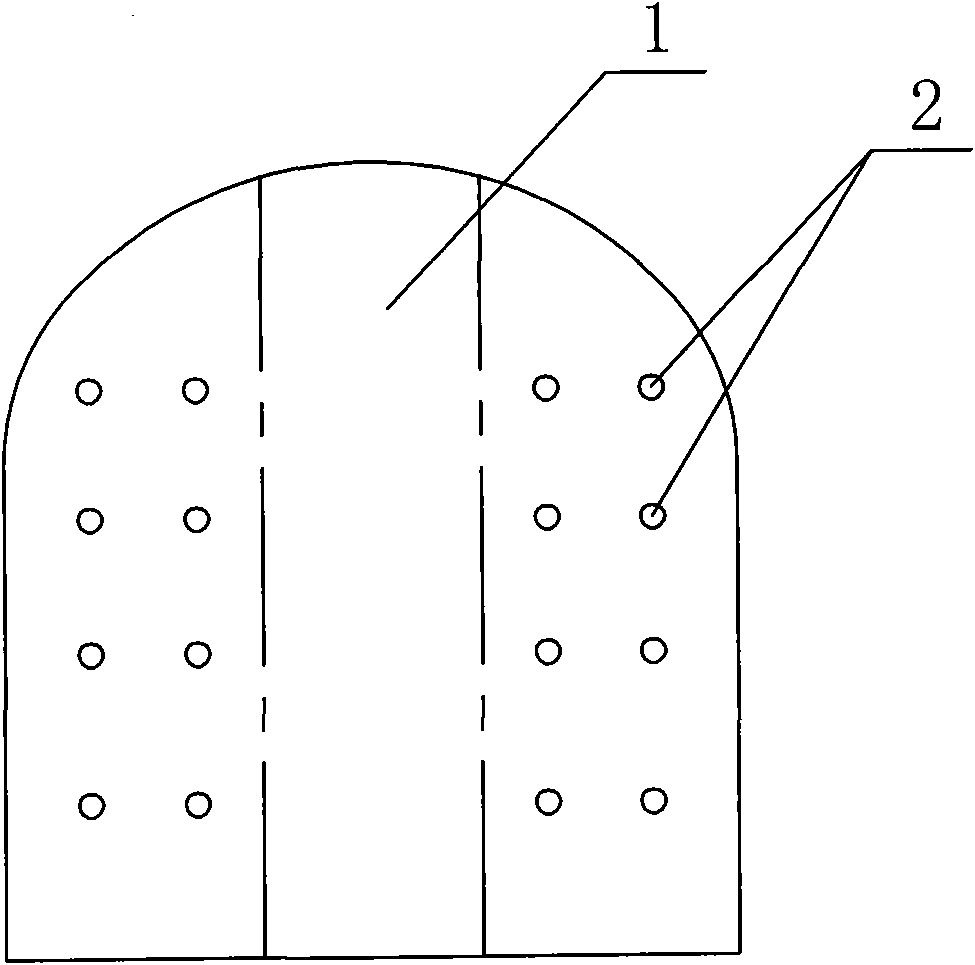

[0028] a. Carry out blast hole layout and charge design according to the conventional cutting plan, and open a V-shaped cutting 1 on the conventional tunnel surface. The distance from the widest part of the cutting to the excavation sideline is 0.3 times the tunnel 3 diameter D , the narrowest part of the cut 1 is 0.15 times the diameter D of the tunnel 3;

[0029] b. Drilling blastholes for excavation and blastholes for stress relief 2 on the digging face, where the layout of the blastholes for caving and blastholes for smooth surfaces in the blastholes for excavation is designed with reference to the conventional arrangement, and the blastholes for stress relief 2 has four columns, a total of sixteen, symmetrically distributed on both sides of the cut 1, and the distance from the excavation line of the two side walls is...

Embodiment 2

[0034] Embodiment 2: Excavation method for prevention and control of strong rockburst at face, characterized in that the specific steps include,

[0035] a. Carry out blast hole layout and charge design according to the conventional cutting scheme, and open a V-shaped cutting 1 on the conventional tunnel face, the distance from the widest part of the cutting to the excavation sideline is 0.3 times the tunnel 3 diameter D , the narrowest part of the cut 1 is 0.15 times the diameter D of the tunnel 3;

[0036] b. Drilling and setting excavation blastholes and stress relief blastholes 2 on the digging face, where the layout of the caving blastholes and smooth blastholes in the excavation blastholes is designed with reference to the conventional layout, and the stress relief blastholes 2 has four columns, a total of sixteen, symmetrically distributed on both sides of the cut 1, and the distance from the excavation line of the two side walls is 1m and 2m respectively. The included...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com