Construction method for deformation control via horizontal whirling jet grouting of long cantilever in soft-rock tunnel

A technology of horizontal jet spraying and deformation control, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems of grout running out, increased man-hours and costs, pile diameter shrinkage, etc., and achieves high stability and increased shear resistance and tensile force, the effect of controlling rock and soil deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

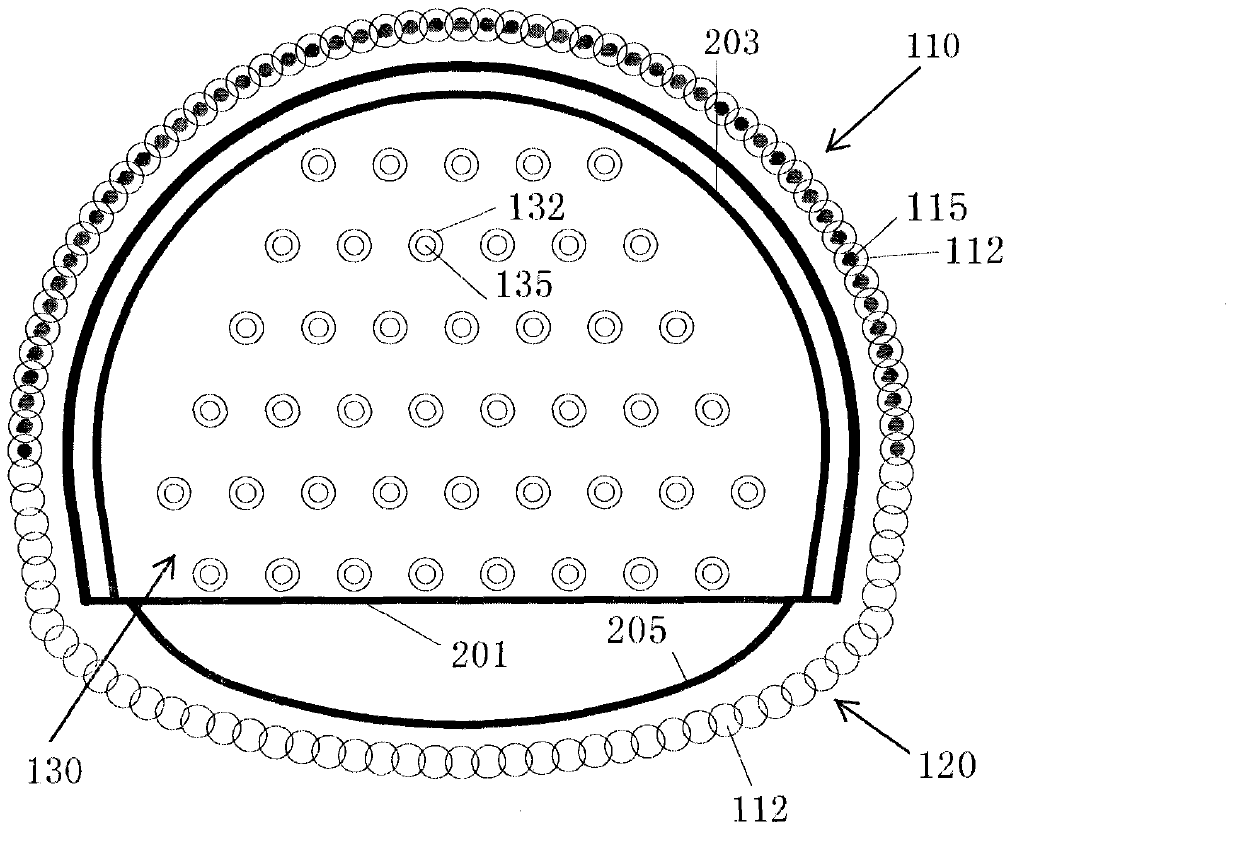

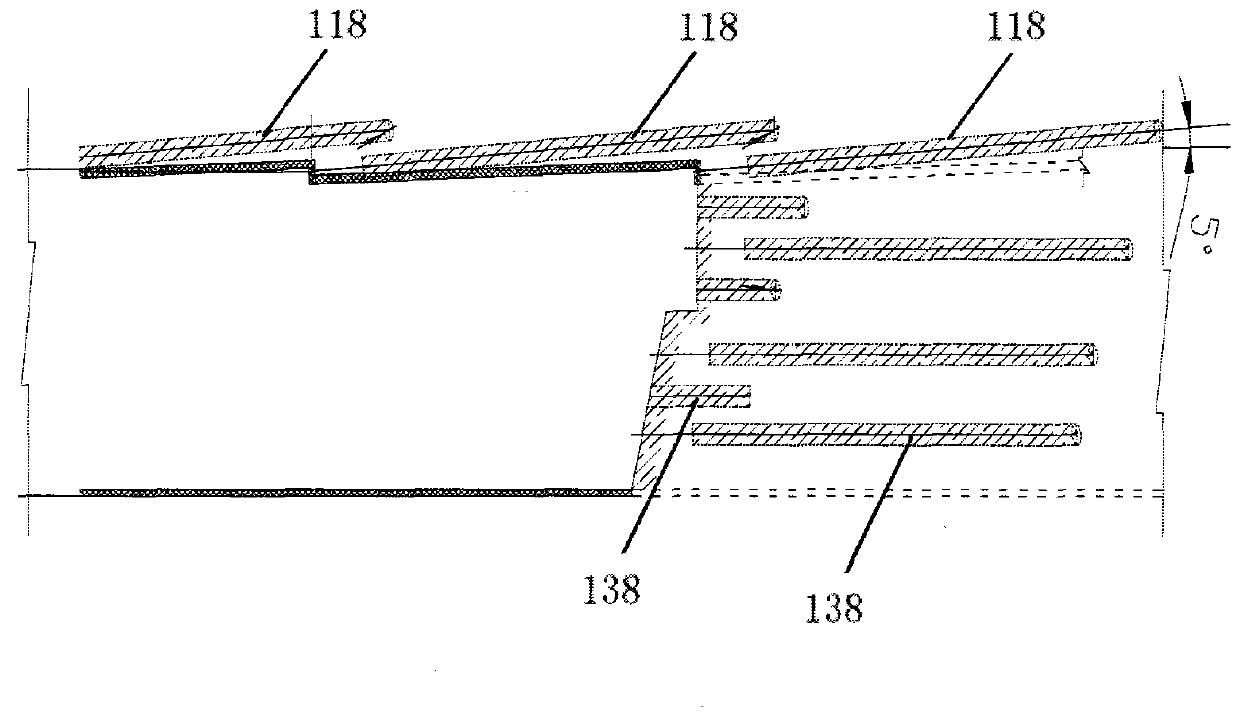

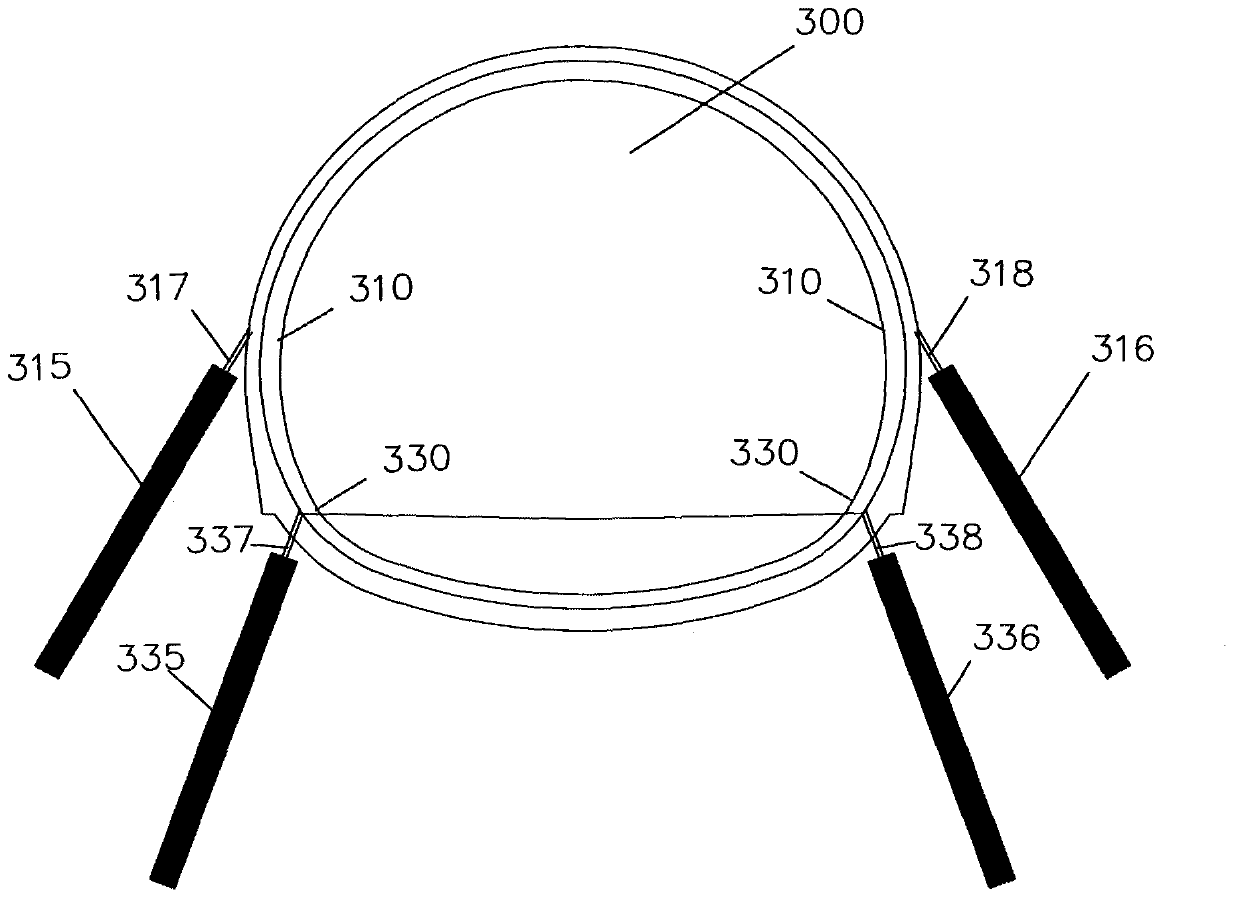

[0039] Refer to attached figure 1 and figure 2 , according to an exemplary embodiment of the present invention, the soft rock tunnel long cantilever horizontal jet spray deformation control construction method includes: (1) according to the predetermined opening position in the tunnel excavation face (face) of the soft rock construction area Drill a first type borehole 112 with prescribed depth and diameter; (2) after completing this first type borehole 112, the cement slurry prepared in advance will be supplied to the end of the first type borehole 112, start the horizontal rotation Grouting makes the high-speed sprayed cement slurry drive the soft rock around the first-type borehole 112 to rotate, stir and fuse together, so that as the drill pipe (not shown) exits the first-type borehole 112, it will move along the first-type borehole 112. The borehole 112 forms the first type pile body 118 from the inside to the outside, and stops the horizontal jet grouting after the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com