High-ground stress soft rock highway tunnel supporting method

A technology for highway tunnels and high ground stress, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as primary lining and secondary lining cracking and damage, difficulty in guaranteeing tunnel construction quality, and affecting construction progress, etc., to achieve long-term guarantee The effect of safety and stability, avoiding multiple renovations, and speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

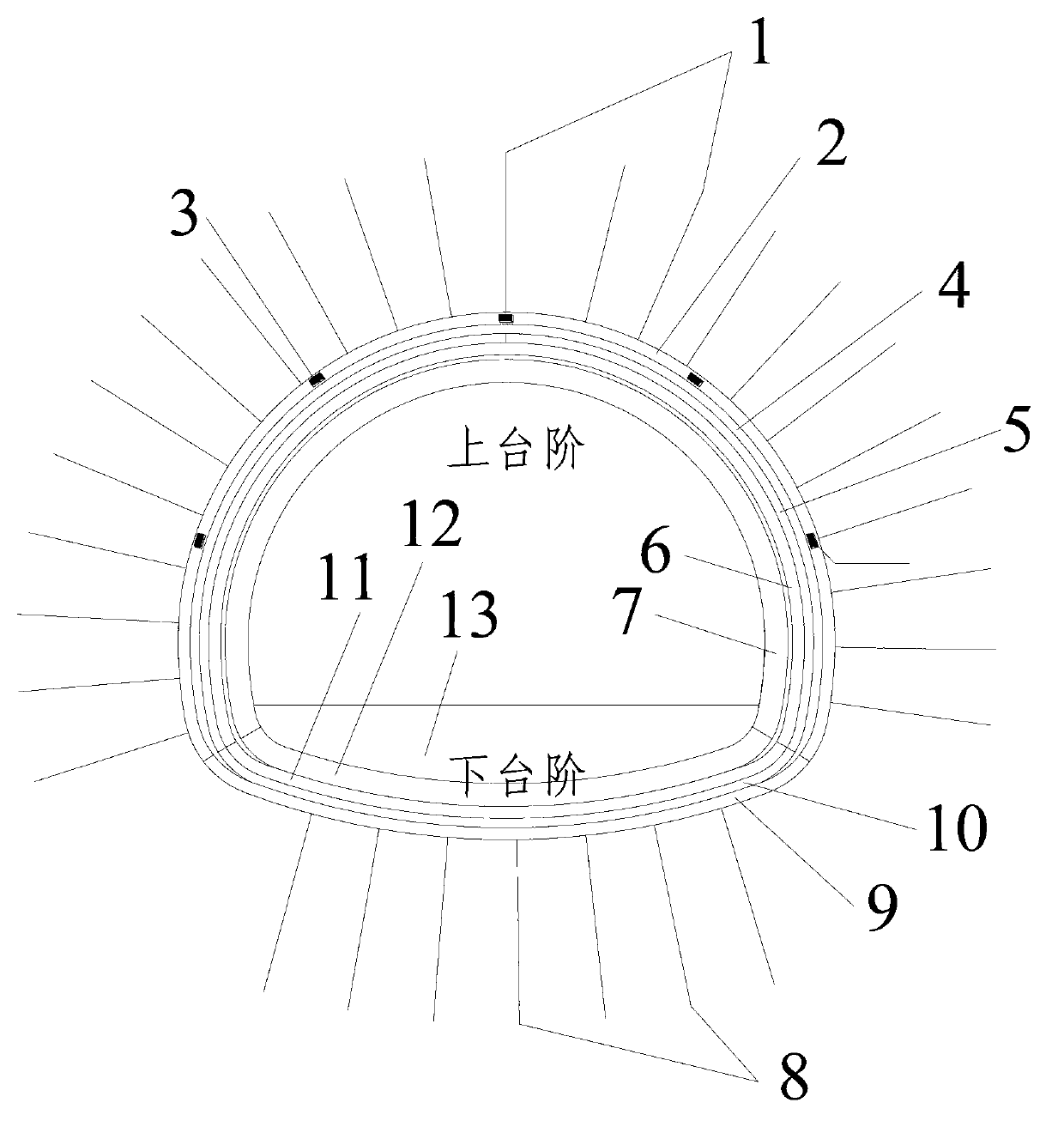

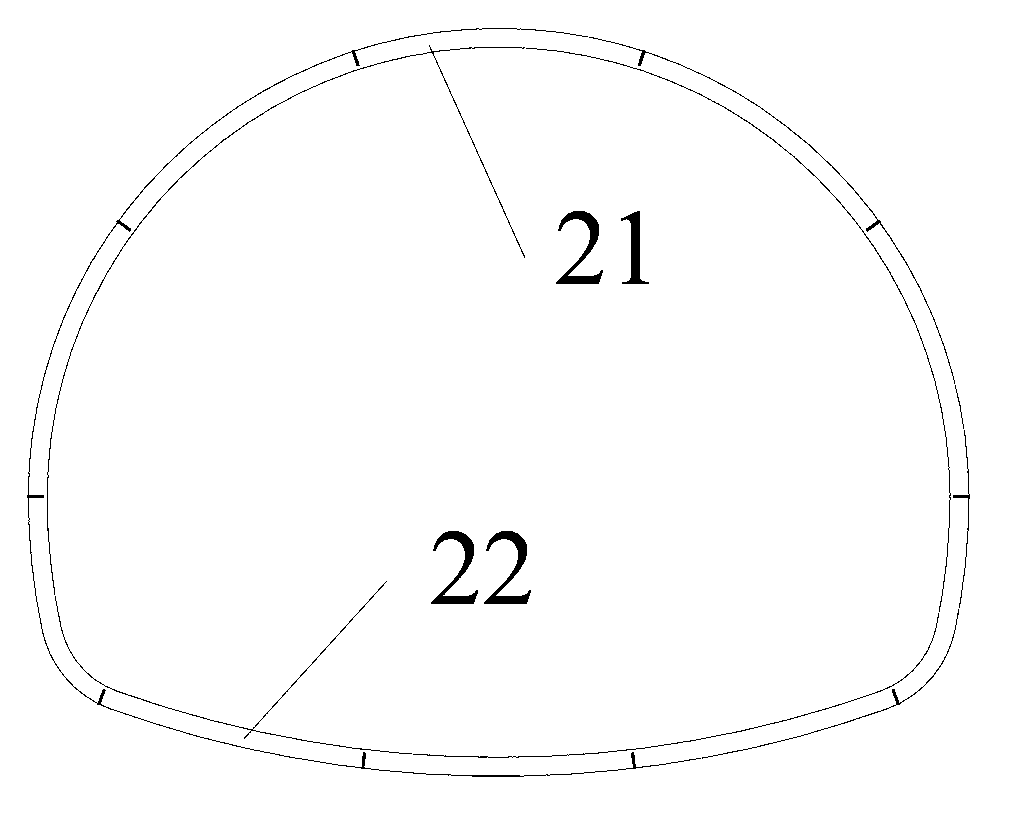

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

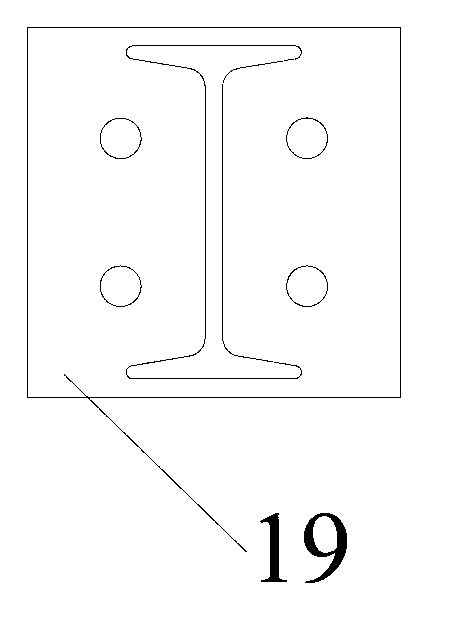

[0033] The principle of the high ground stress soft rock highway tunnel support method is as follows: Aiming at the characteristics of high stress level of surrounding rock and large deformation of the tunnel in the high ground stress soft rock highway tunnel, anchor shotcrete support + foam concrete buffer layer + secondary shotcrete + secondary lining The composite lining support form fully absorbs the large deformation of the surrounding rock and jointly bears the pressure of the surrounding rock. At the same time, the inverted arch anchor rod and anchor cable are used to control the upward deformation of the tunnel bottom, effectively protecting the permanent structure of the tunnel and ensuring the safety and stability of the tunnel.

[0034] A high ground stress soft rock highway tunnel support method, the specific construction steps are as follows:

[0035] 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com