Fatigue tester for paving rotary wheel type bridge

A fatigue testing machine, wheel-type technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of low test efficiency, limited operating speed, low operating speed, etc., to overcome Experimental data is not true, shortened test time, and the effect of short test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

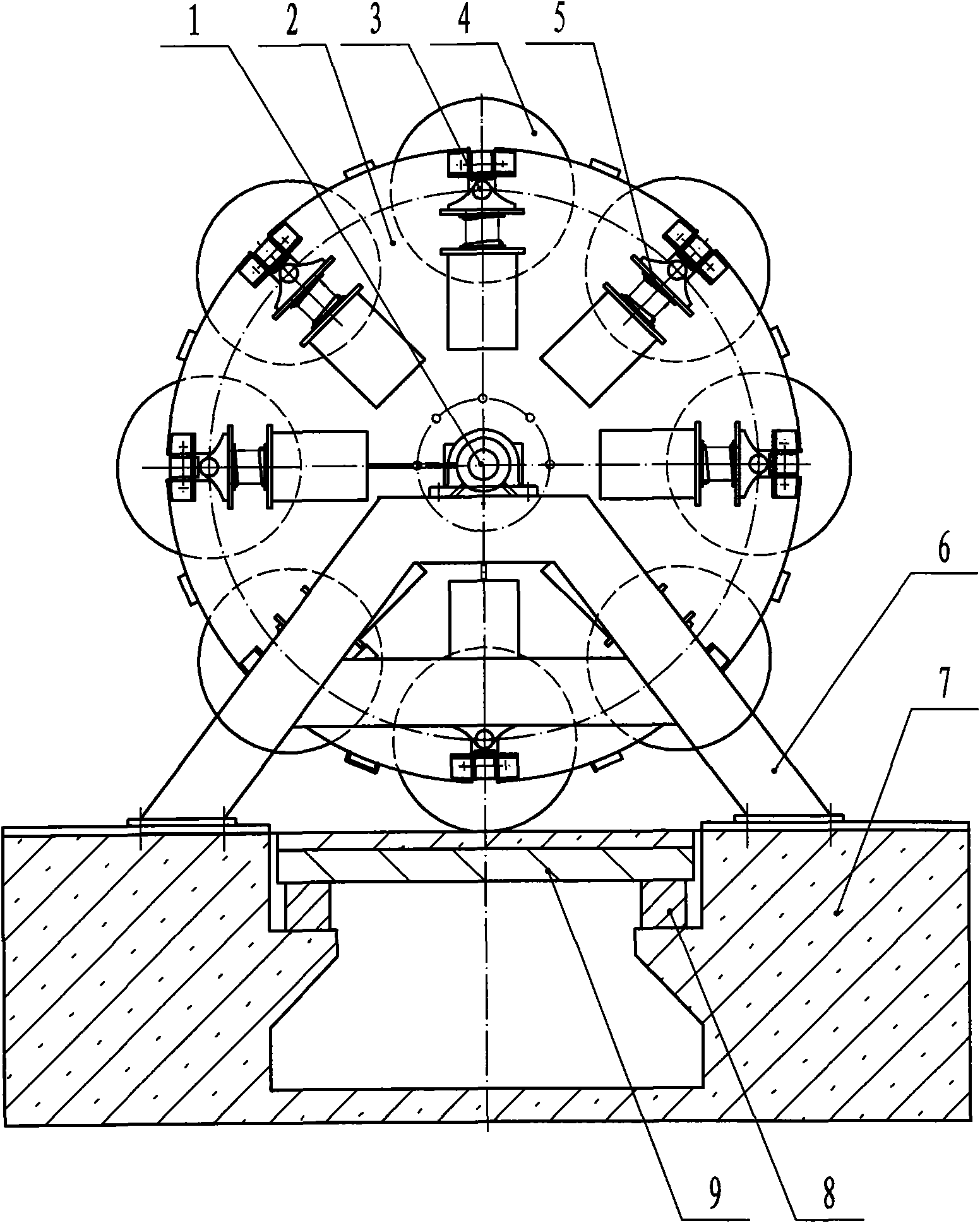

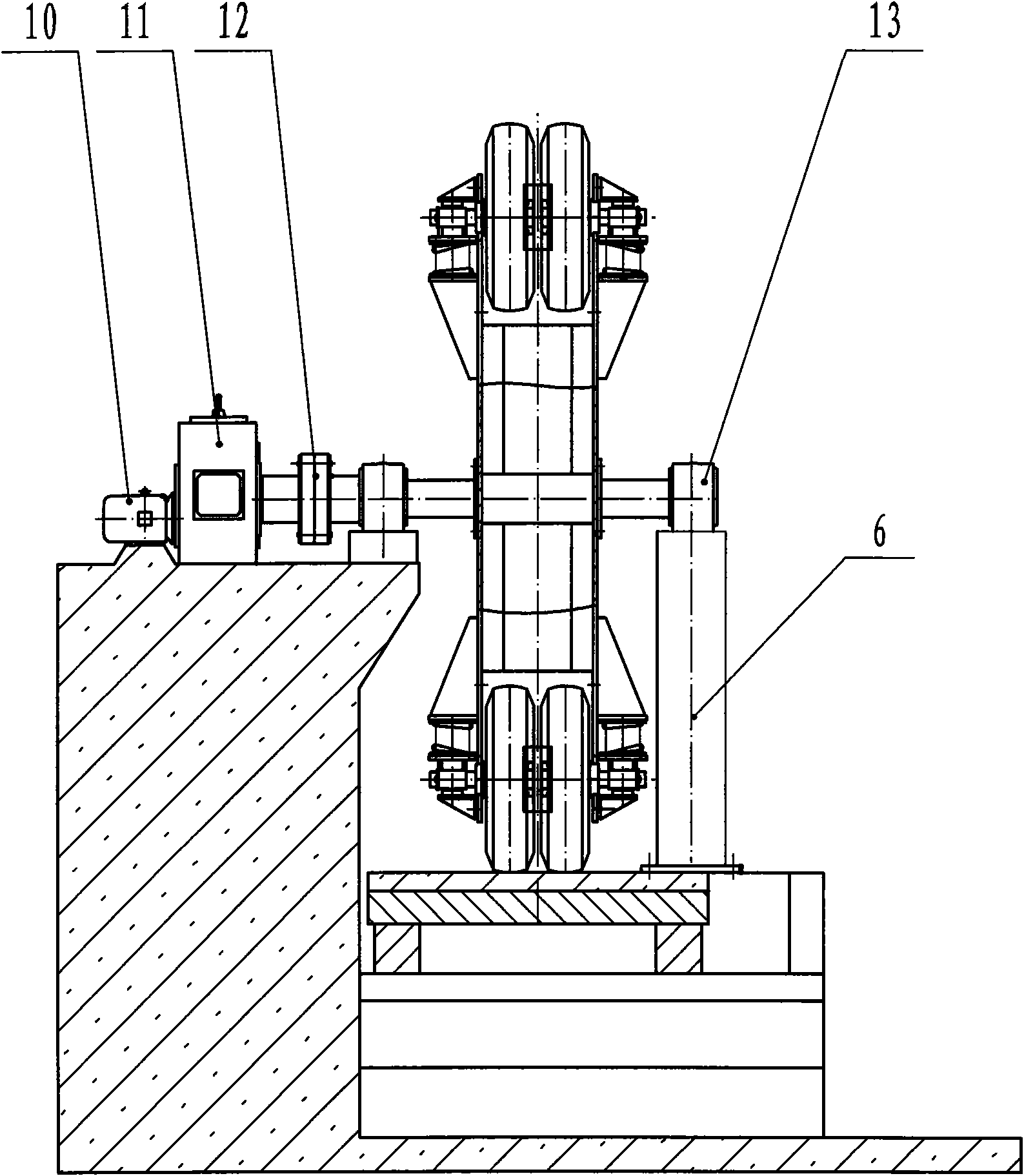

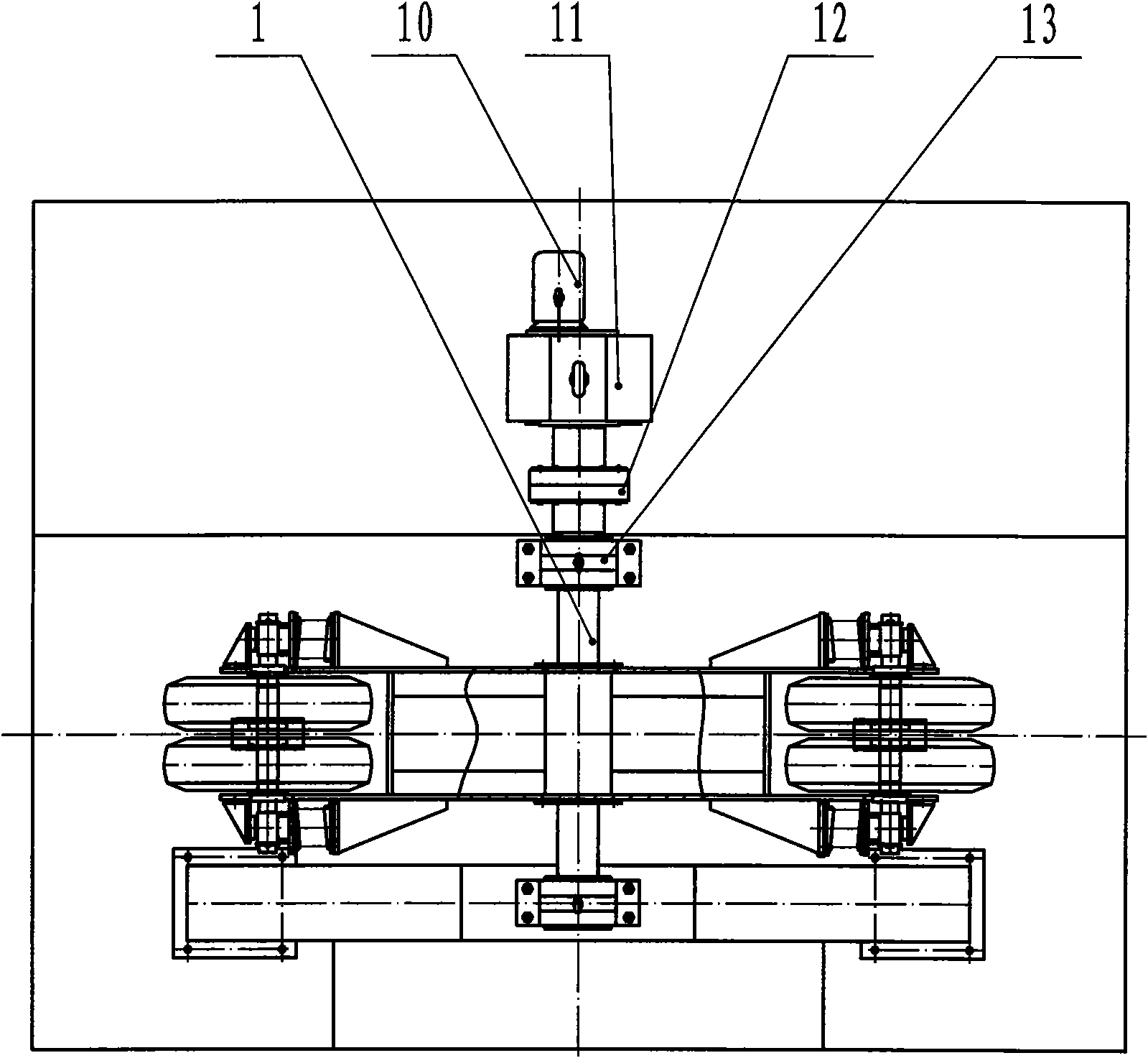

[0017] exist figure 1 , 2 , 3, the runner type bridge pavement fatigue testing machine of the present embodiment is made up of drive shaft 1, runner 2, axle 3, automobile wheel 4, loading mechanism 5, drive shaft support 6, concrete base 7, test piece Support 8, test piece 9, motor 10, reducer 11, coupling 12, bearing support 13 are connected to form.

[0018] On the concrete base 7, the motor 10 and the speed reducer 11 are fixedly connected with a threaded fastening connector, the output shaft of the motor 10 is connected with the speed reducer 11 with a key coupling, and the output shaft of the speed reducer 11 is connected with the shaft coupling 12. Drive shaft 1 is connected. On the concrete base 7, a drive shaft support 6 is fixedly connected with a threaded fastening joint, and the upper end of the drive shaft support 6 is fixedly connected with a bearing support 13 with a threaded fastening joint, and the drive shaft 1 is installed on the bearing support 13. 1 is f...

Embodiment 2

[0024] In this embodiment, four wheel shafts 3 are installed on the runner 2 in the circumferential direction of the same radial direction, and each wheel shaft 3 is fixedly connected with two automobile wheels 4 with couplings, and each wheel shaft 3 A loading mechanism 5 is fixedly connected to the outer side of the upper and runner 2 with couplings. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0026] In this embodiment, a wheel shaft 3 is installed on the runner 2 in the circumferential direction of the same radial direction, and two automobile wheels 4 are fixedly connected with a coupling on the wheel shaft 3. On the wheel shaft 3 and the runner The outside of 2 is fixedly connected with loading mechanism 5 with connector. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com