File head broken by water injection

A technology for breaking pile heads and pile heads, which is used in sheet pile walls, construction, infrastructure engineering, etc., can solve problems such as the useless value of pile head concrete, poor construction environment for workers, and distortion of steel bars at the pile head, so as to overcome construction shortcomings. , the construction progress is fast, the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

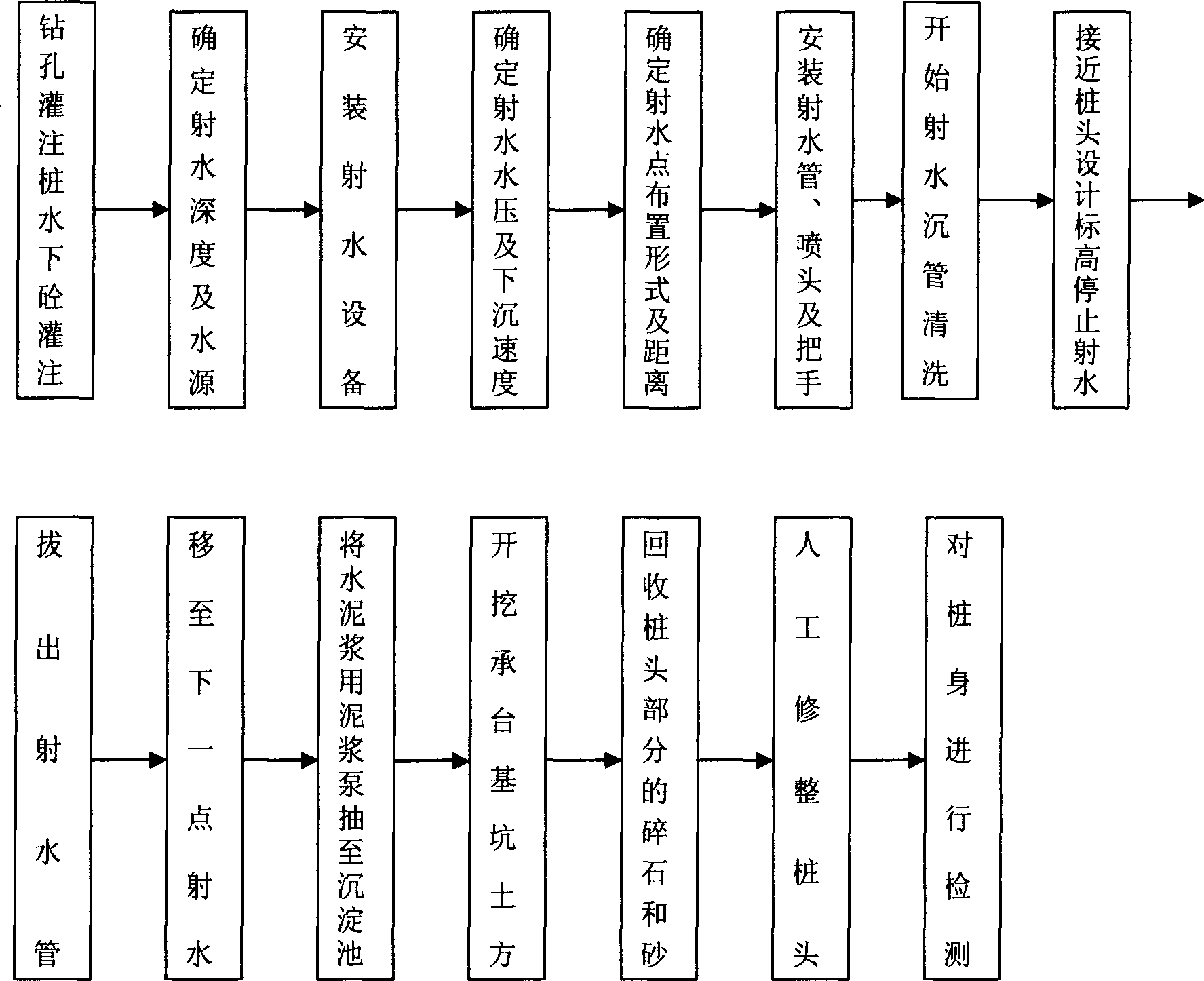

Method used

Image

Examples

specific Embodiment

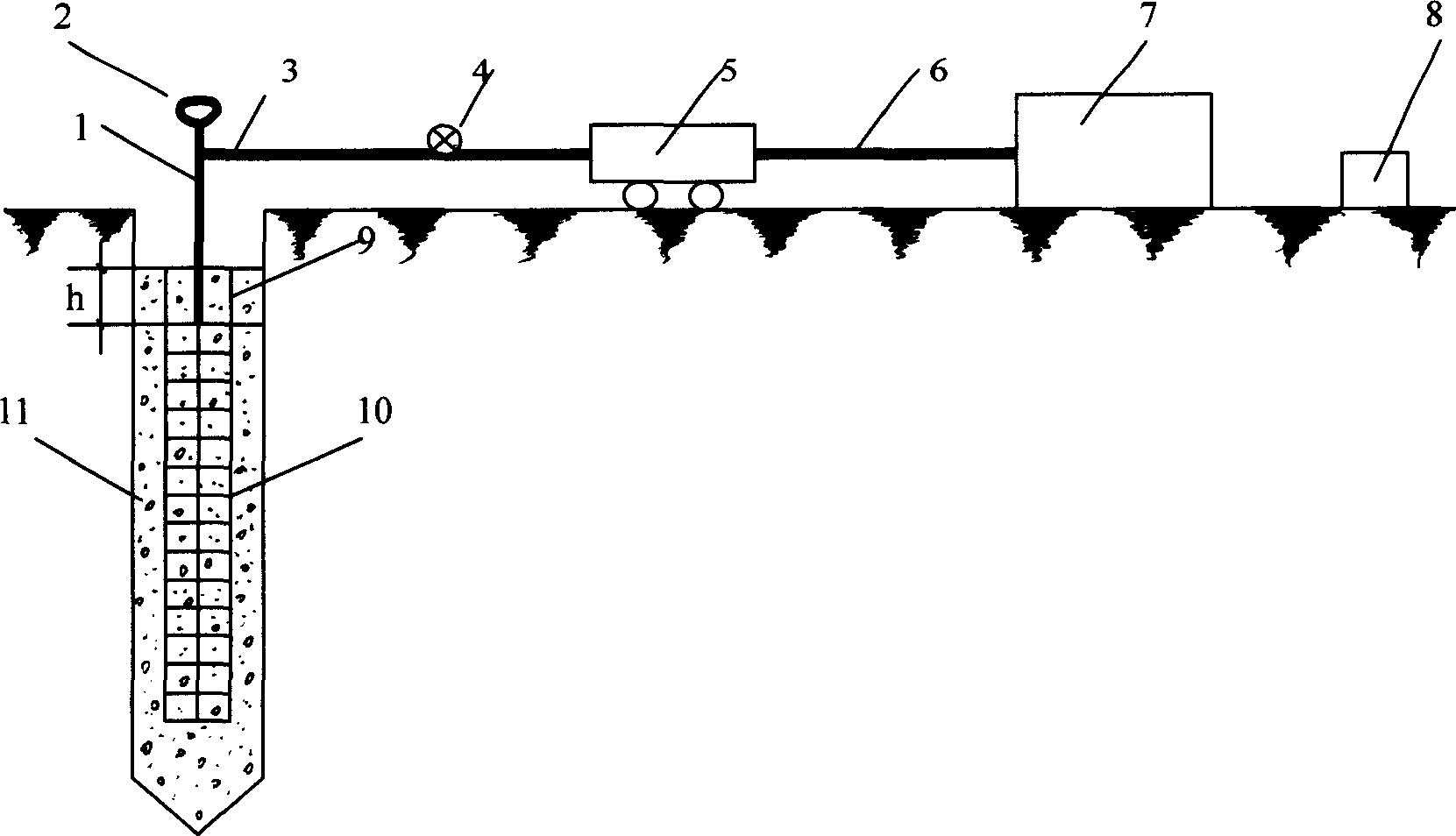

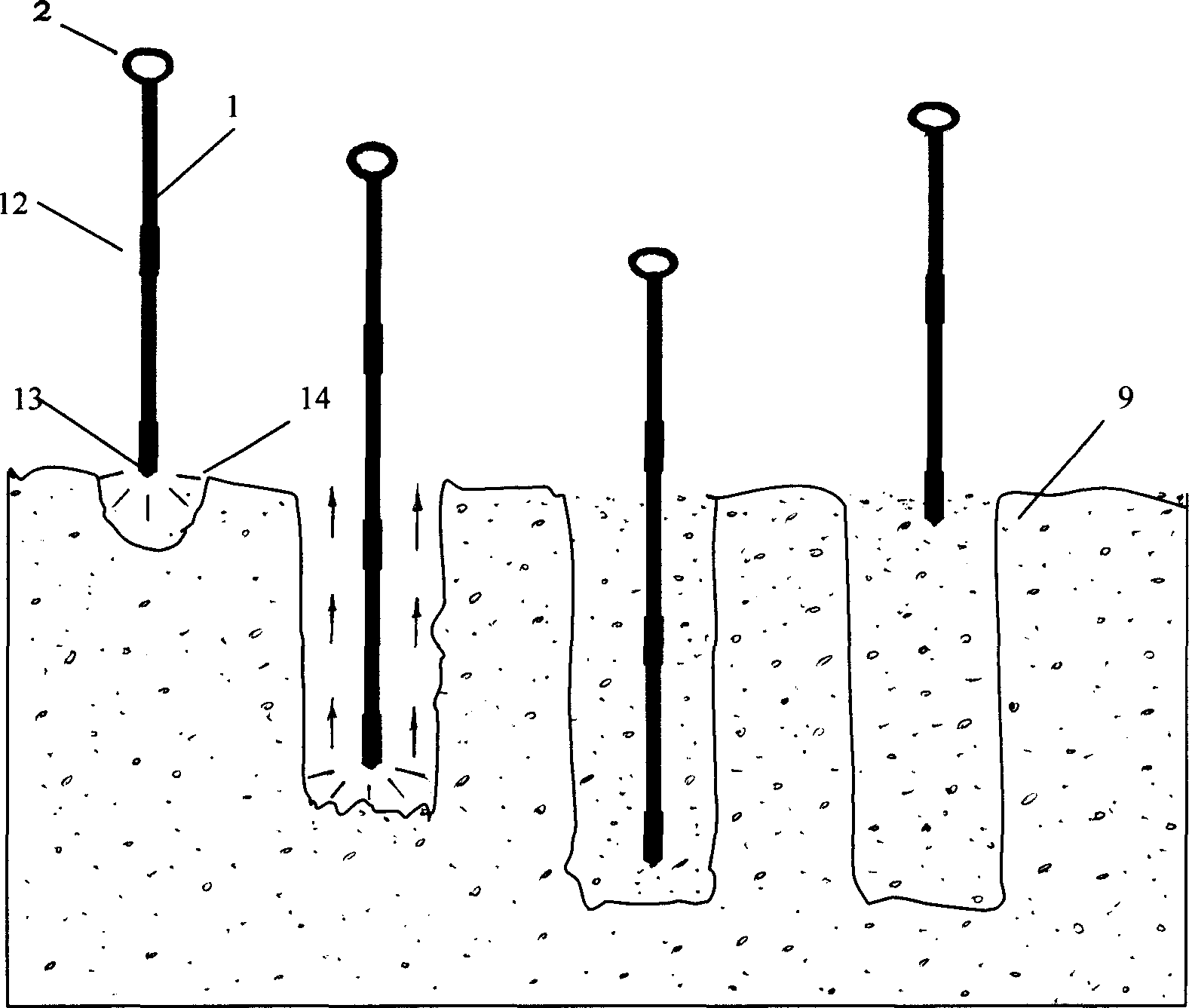

[0017] Bored cast-in-situ piles of pier No. 33 on the left side of the east section of Wenshui Road Viaduct on Shanghai Middle Ring Road (A2.5 bid). 3.3 meters, and the design elevation of the pile top is +0.91 meters. According to the regulations of Shanghai Municipal Engineering Bridge Construction Code: the reserved concrete height above the design elevation of the pile top of the bored pile is not less than 2 meters, and the water pressure of the jet pipe and outlet pipe design is allowed 8Mpa, the length of the jet pipe is designed to be 3 meters, divided into three sections, each section is 0.8 to 1.2 meters long, the inner diameter of the jet pipe is 3 cm, and the wall thickness is 5 mm. Port steel sleeve (with sealing rubber gaskets at both ends) connection. The aperture of the nozzle is 1.0cm, and the nozzle is a cone. The outlet pipe chooses a high-pressure resistant (not less than 8Mpa) flexible bellows pipe with an inner diameter of 5.0cm. The water inlet pipe choo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com