A construction method for a high-speed oblique-leg rigid-frame bridge

A construction method and technology of inclined legs, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of reaction force support, uncontrollable deformation of inclined leg supports, and waste of profile cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with accompanying drawing:

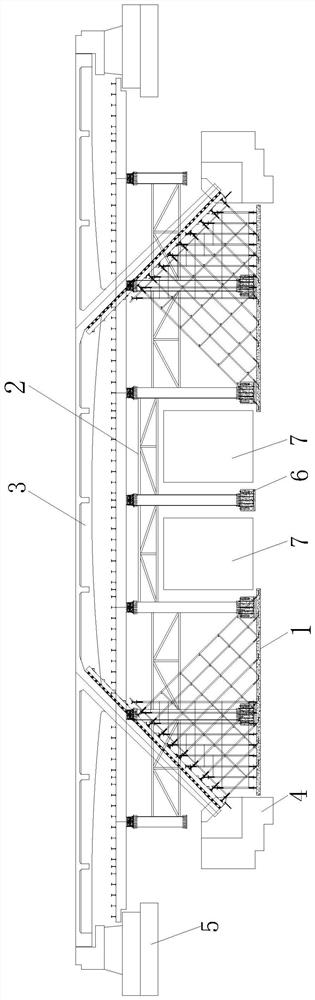

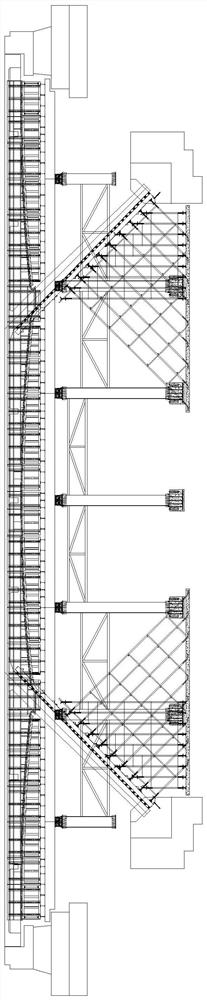

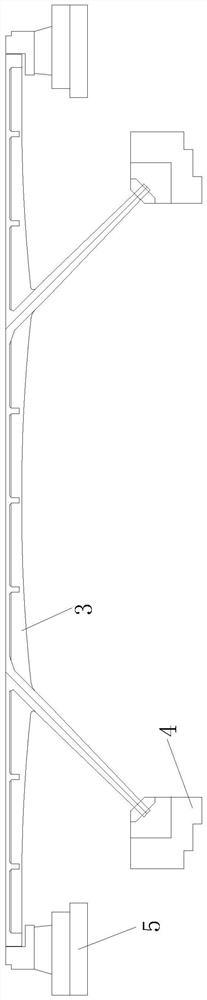

[0067] like Figure 1-15 It shows a schematic diagram of the construction structure adopted by the construction method of the rigid-frame flyover with oblique legs spanning high speed;

[0068] The present application relates to a construction method for a high-speed oblique-leg rigid-frame flyover, comprising the following steps:

[0069] S1. According to the design plan of the support, the foundation shall be leveled, and the full support 1 of the inclined legs and the steel pipe column supporting the beam body shall be erected;

[0070] S2. Install the bottom formwork of the oblique leg part and the steel formwork of the beam body part;

[0071]S3. Simulate the construction load to preload the support, monitor and record according to the specifications, and measure the elastic deformation and inelastic deformation of the support;

[0072] S4. Accurately adjust the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com