An integrated manhole cover module and its construction method

A technology of integrated inspection well and well cover, applied in the field of integrated inspection well cover module and its construction, can solve the problems of slow construction progress, low construction quality, long construction period, etc., and achieve the effect of slow construction progress, reduced workload and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

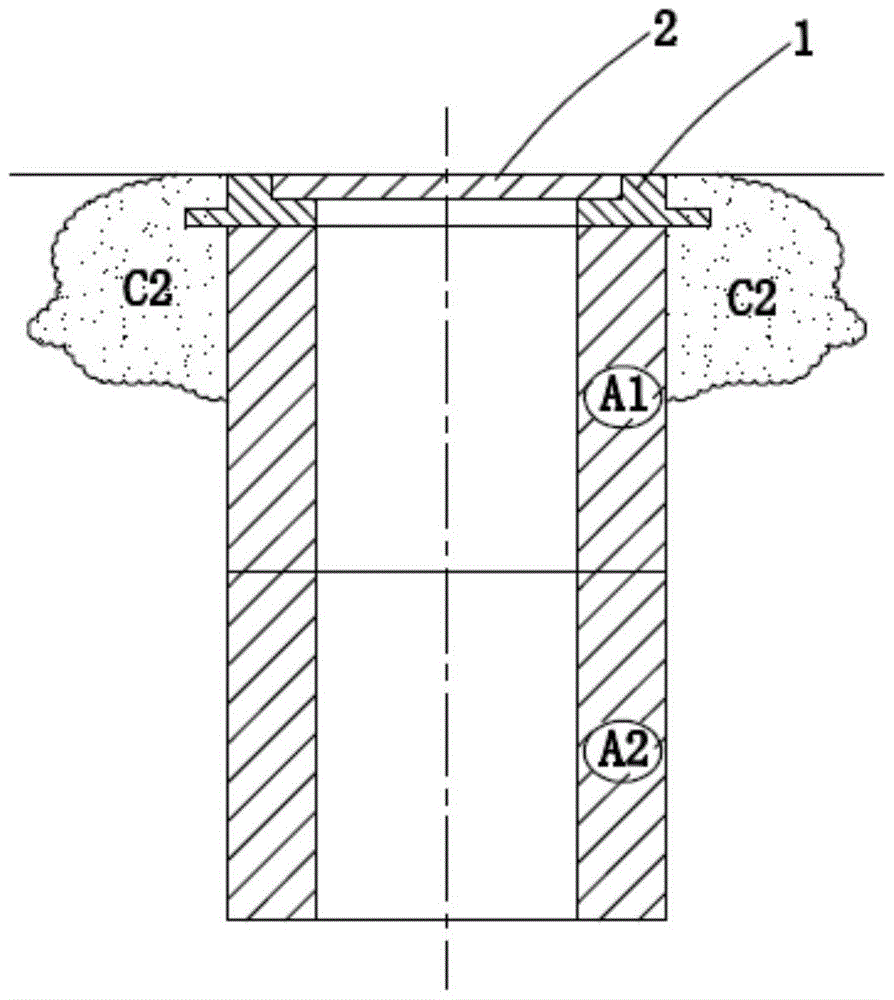

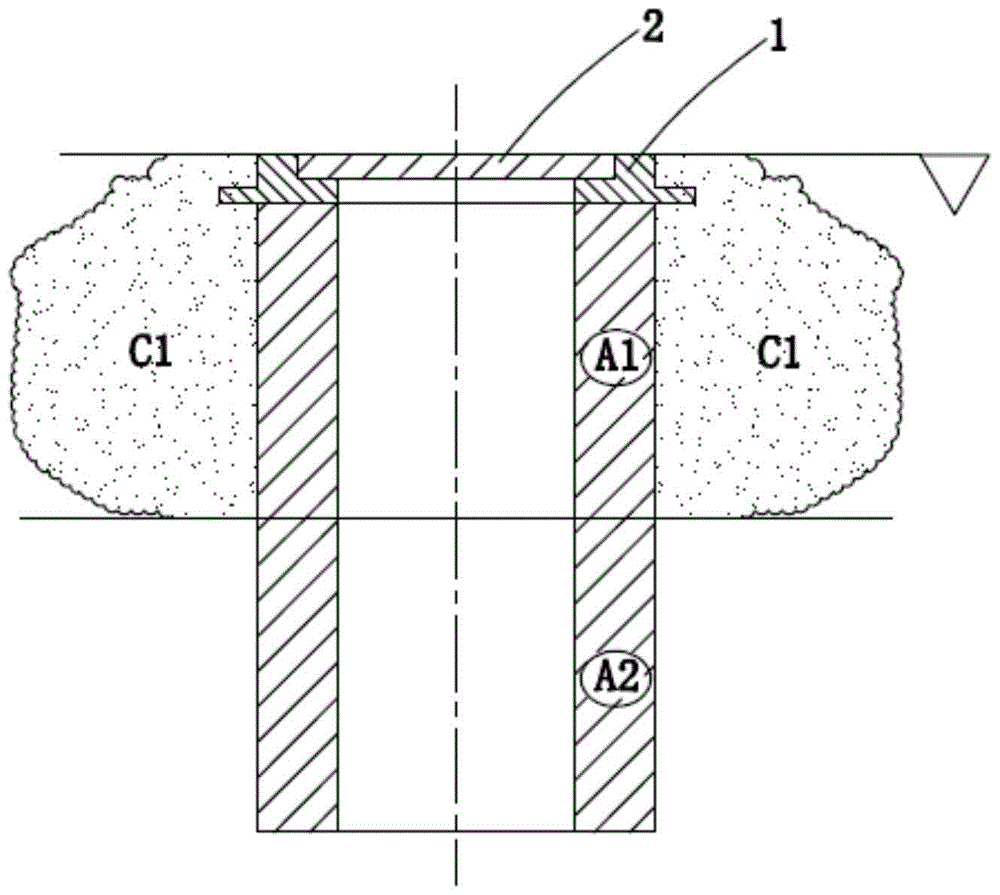

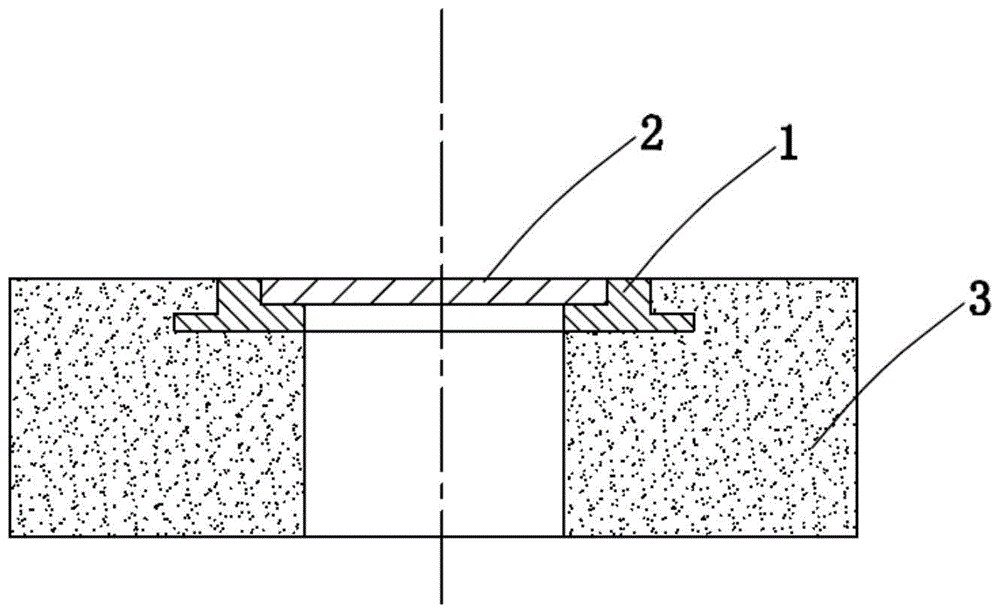

[0039] Embodiment 1: In conjunction with the accompanying drawings, the integrated inspection well cover module of this embodiment includes a hollow cylindrical module body 3, a well cover base 1, and a well cover 2 matching the well cover base. The well cover can be cast iron or steel structure, and the well cover The base can be hinged or split, and connected with anti-theft bolts and nuts. The module body 3 is prefabricated by reinforced concrete. The manhole cover base 1 is pre-buried on the top surface of the module body 3. The top surface of the manhole cover 2 is flush with the top surface of the module body 3. After the construction is completed, it is on the same plane as the forming ground to ensure smoothness of the road.

[0040] The aperture of the hollow part of the module body 3 is matched with the inner diameter of the inspection well pipe, and a safety net hook is provided on the hole wall of the module body for hanging the safety net, and an installation and ...

Embodiment 2

[0050] Embodiment 2: for the transformation and maintenance of the old road inspection well system, it comprises the following steps:

[0051] A. When renovating old road inspection wells or replacing damaged inspection well structures, first seal the inspection wells in the inspection wells to prevent concrete and sundries from falling into the wells during milling;

[0052] B. Centering on the center line of the old wellhead, mill a cylindrical sinkhole on the ground. The size and depth of the milled pit are consistent with the size and thickness of the inspection well cover module to be installed; in the above steps, the closed position should be lower than the bottom of the sinkhole;

[0053] C. Remove the dust and loose parts on the pit wall and pit bottom;

[0054] D. Put the inspection shaft cover module into the cylindrical sinkhole with lifting equipment, level and fix it after installation in place; grout in the horizontal grouting groove 4 of the module body in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com