Negative polar plate needle-spraying counter-flow cleaning device in subsequent electrolysis working section of electrolytic zinc

A technology of countercurrent cleaning and electrolysis of zinc, applied in the electrolysis process, electrolysis components, photography process and other directions, can solve the problem of large amount of heavy metal wastewater, reduce the amount of clean water, improve the washing efficiency, and realize the effect of multiple recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

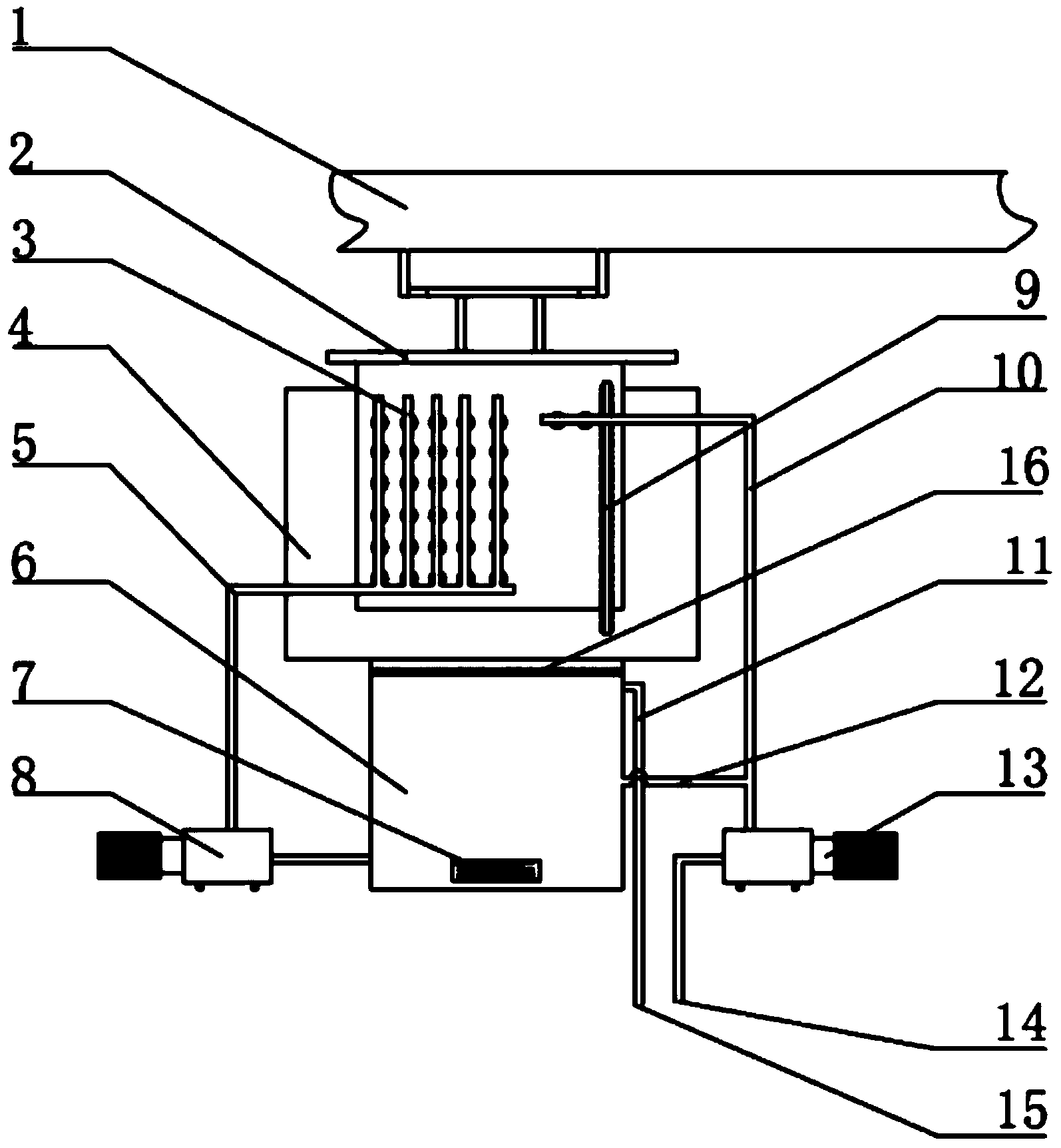

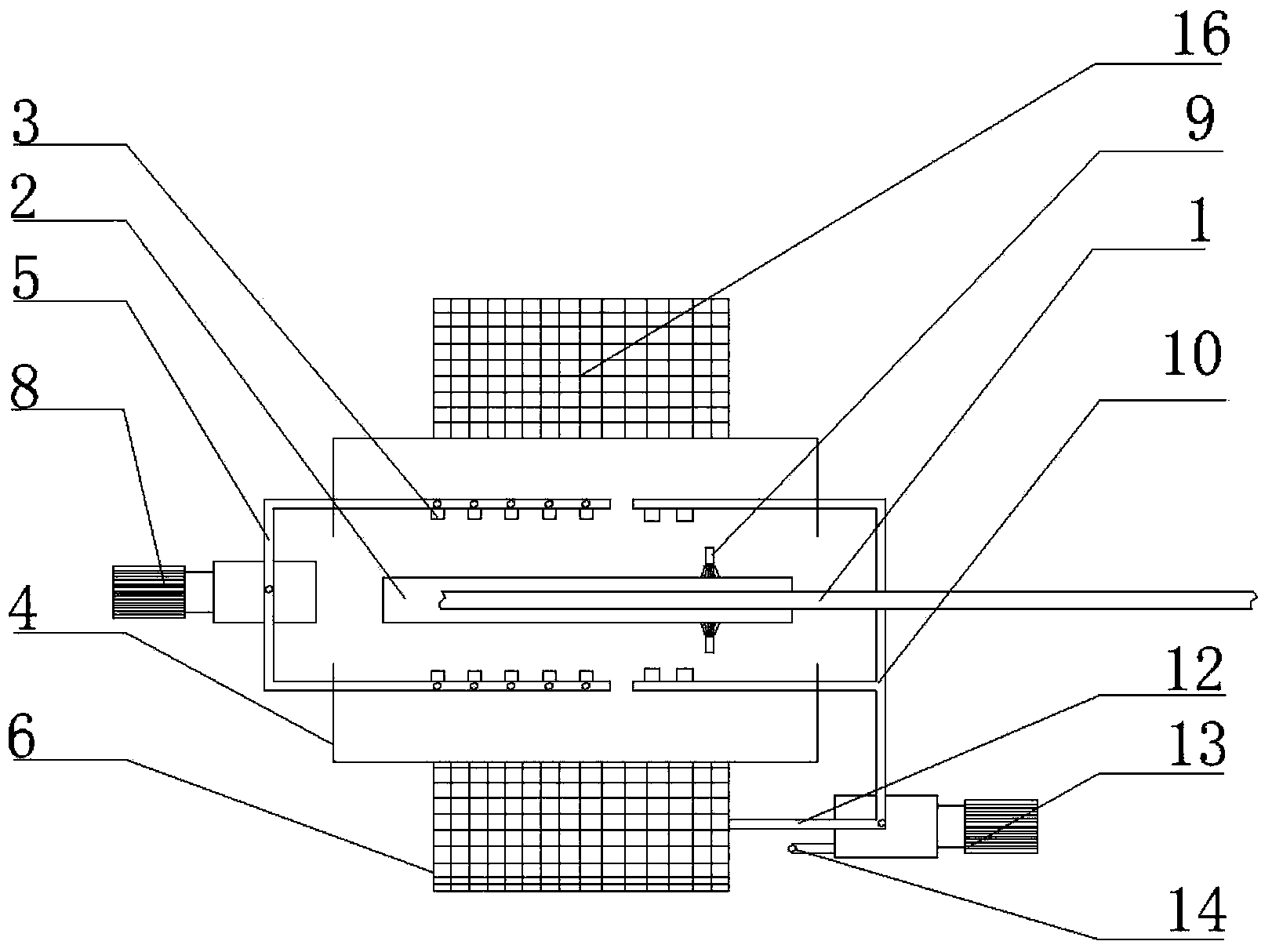

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0022] A needle-spray countercurrent cleaning device for cathode plates in the follow-up section of electrolytic zinc electrolysis, such as figure 1 , figure 2 As shown, it includes a conveyor chain 1, a pole plate 2, a circulating water washing assembly, a clear water washing assembly and a row brush 9, the pole plate 2 is connected to the conveying chain 1, and the circulating water washing assembly is connected to the clear water washing assembly connected, the clean water washing assembly is connected to the pole plate 2, and the row brush 9 is installed on the circulating water washing assembly. The transmission chain 1 is a power transmission mechanism for the pole plate 2, and the pole plate 2 is suspended ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com