Method for recovering secondary salts from desulfurization liquid and recycling desulfurization liquid

A desulfurization liquid and secondary salt technology, applied in chemical instruments and methods, copper sulfate, thiocyanic acid, etc., can solve the problems that the secondary salt of the desulfurization liquid cannot be recycled and the desulfurization liquid cannot be effectively recycled, and achieve effective The effect of recycling, reduction of secondary salt content, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

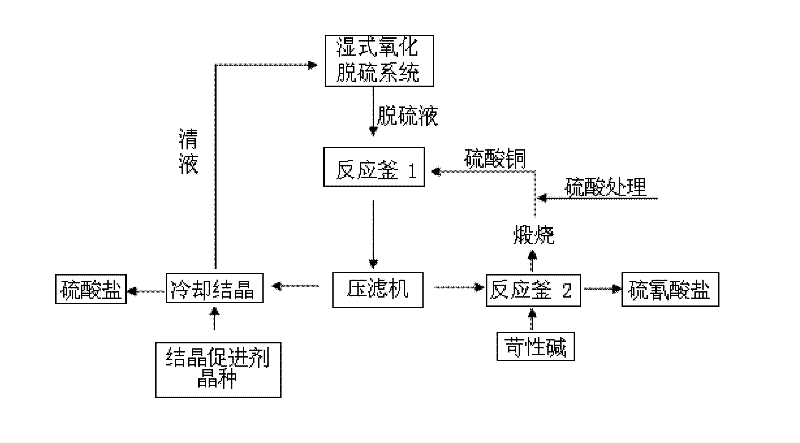

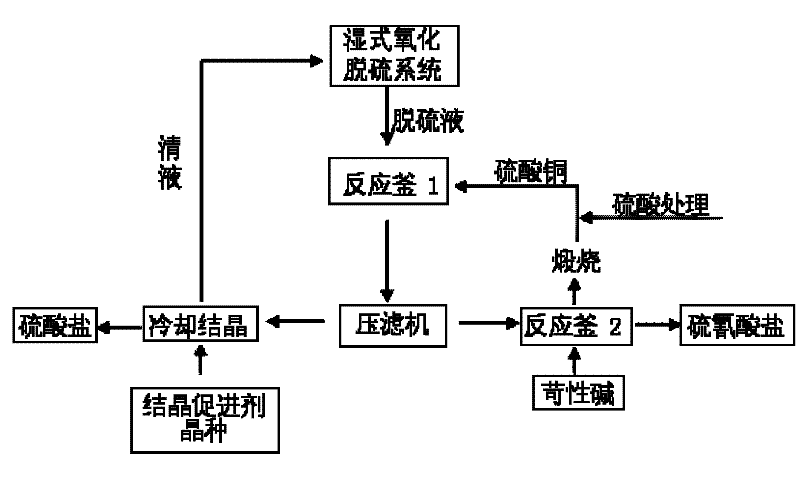

Method used

Image

Examples

Embodiment 1

[0034] 100mL desulfurization solution, containing sodium thiocyanate 165g / L, sodium thiosulfate 72g / L, sodium sulfate 56g / L, temperature 40°C, add CuSO 4 ·5H 2 O 50g, stirred, reacted 60min in reactor 1, filtered to obtain intermediate product CuSCN, containing sodium thiocyanate 2.42g / L in the filtrate, sodium thiosulfate 26.7g / L, sodium sulfate 62.2g / L, thiocyanate The removal rates of sodium and sodium thiosulfate were 98.3% and 56.1%, respectively.

[0035] Add 5g Na to the filtrate 2 SO 4 10H 2 O seed crystal and 20g crystallization accelerator, crystallization accelerator is made up of 5% soda ash and 95% alcohol amine by mass percentage, and alcohol amine is made up of triethanolamine and 50% methyldiethanolamine of mass percentage, stirs, cools Precipitate Na at 0-5°C 2 SO 4 10H 2 O, crystallization time 24-360 hours, crystallization to obtain 12.8gNa 2 SO 4 10H 2 O, the removal rate of sodium sulfate in the desulfurization solution is 72.3%. The clear liqui...

Embodiment 2

[0038] 100mL desulfurization liquid, containing sodium thiocyanate 131g / L, sodium thiosulfate 36.8g / L, sodium sulfate 71.1g / L, temperature 40°C, add CuSO 4 ·5H 2 O 41g, stirred, reacted 60min in reactor 1, filtered to obtain intermediate product CuSCN, containing sodium thiocyanate 1.8g / L in the filtrate, sodium thiosulfate 3.4g / L, sodium sulfate 74.6g / L, thiocyanate The removal rates of sodium and sodium thiosulfate were 98.5% and 89.4%, respectively.

[0039] Add 5g Na to the filtrate 2 SO 4 10H 2 Crystal seed and 30g crystallization accelerator, crystallization accelerator is made up of the alkali of mass percentage 30% and the alcohol amine of 70%, alkali is made up of the caustic soda of mass percentage 50% and the soda ash of 50%, alcohol amine is made up of the three Composed of ethanolamine and 95% methyldiethanolamine, stirred, cooled to 0-5°C to precipitate Na 2 SO 4 10H 2 O, crystallization time 24-360 hours, crystallization to obtain 17.2g Na 2 SO 4 10H 2...

Embodiment 3

[0042] 100mL desulfurization solution, containing sodium thiocyanate 171g / L, sodium thiosulfate 48.6g / L, sodium sulfate 67.7g / L, temperature 40°C, add CuSO 4 ·5H 2 O 50g, stirred, reacted 60min in reactor 1, filtered to obtain intermediate product CuSCN, containing sodium thiocyanate 7.5g / L in the filtrate, sodium thiosulfate 5.86g / L, sodium sulfate 72.4g / L, thiocyanate The removal rates of sodium and sodium thiosulfate were 94.8% and 85.8%, respectively.

[0043] Add 5g seed crystal and 25g crystallization accelerator in the filtrate, the crystallization accelerator is made up of the caustic soda of 20% by mass percentage and the alcohol amine of 80%, and the alcohol amine is made up of the triethanolamine of 95% by mass percent and the methyldiethanolamine of 5% , stirred, cooled to 0-5°C to precipitate Na 2 SO 4 10H 2 O, crystallization time 24-360 hours, crystallization to obtain 16.5gNa 2 SO 4 10H 2 O, the removal rate of sodium sulfate in the desulfurization solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com