Industrial water-saving agent, preparation method and applications thereof

An industrial and additive technology, applied in chemical instruments and methods, descaling and water softening, water/sewage treatment, etc., can solve the problems of accelerating the volatilization of hydrophobic agents, easily destroying the barrier layer, affecting the water-saving effect, etc., and achieving evaporation loss. Less, easy to use, significant water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

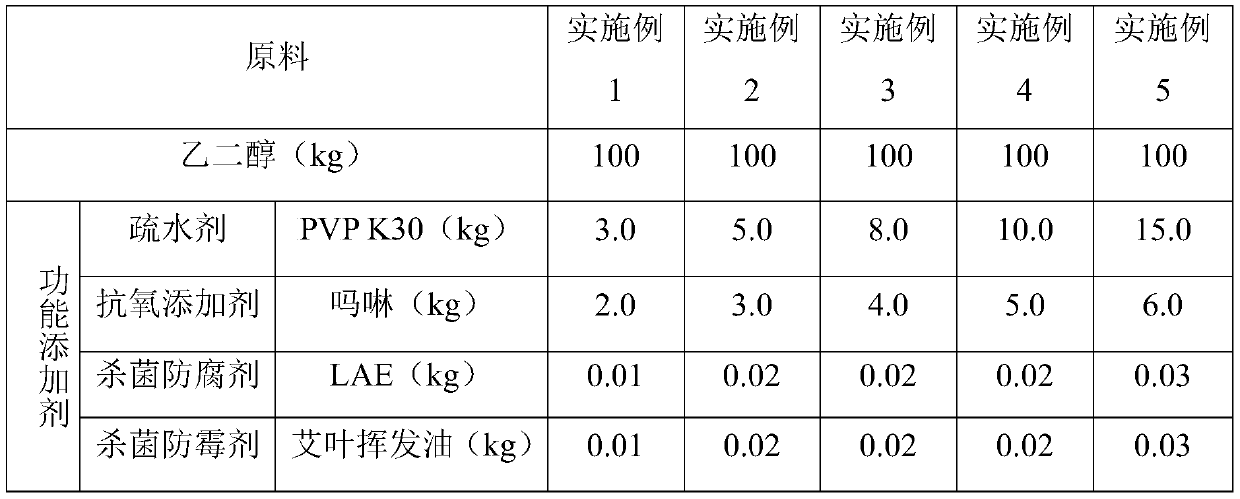

Embodiment 1

[0029] Raw materials: 100kg ethylene glycol and 5.02kg functional additives (including 3.0kg hydrophobic agent, 2.0kg antioxidant additive, 0.01kg bactericidal preservative and 0.01kg bactericidal antifungal agent).

[0030] Preparation steps: Take 20kg of ethylene glycol and add it to the mixing kettle, heat it to 40°C; take 3.0kg of hydrophobic agent, 2.0kg of antioxidant additive, 0.01kg of bactericidal preservative, and 0.01kg of bactericidal and antifungal agent into the mixing kettle, Stir and mix evenly; add the remaining 80kg of ethylene glycol into the mixing kettle, stir and mix evenly, pack into barrels after cooling, and seal and store to prepare the industrial water-saving agent.

Embodiment 2

[0032] Raw materials: 100kg ethylene glycol and 8.04kg functional additives (including 5.0kg hydrophobic agent, 3.0kg antioxidant additive, 0.02kg bactericidal preservative and 0.02kg bactericidal antifungal agent).

[0033] Preparation steps: Take 25kg of ethylene glycol and add it to the mixing kettle, heat it to 50°C; take 5.0kg of hydrophobic agent, 3.0kg of antioxidant additive, 0.02kg of bactericidal preservative, and 0.02kg of bactericidal and antifungal agent into the mixing kettle, Stir and mix evenly; add the remaining 75kg of ethylene glycol into the mixing kettle, stir and mix evenly, pack into barrels after cooling, and seal and store to prepare the industrial water-saving agent.

Embodiment 3

[0035] Raw materials: 100kg ethylene glycol and 12.04kg functional additives (including 8.0kg hydrophobic agent, 4.0kg antioxidant additive, 0.02kg bactericidal preservative and 0.02kg bactericidal antifungal agent).

[0036] Preparation steps: Take 30kg of ethylene glycol and add it to the mixing kettle, heat it to 60°C; sequentially take 8.0kg of hydrophobic agent, 4.0kg of antioxidant additive, 0.02kg of bactericidal preservative, and 0.02kg of bactericidal and antifungal agent into the mixing kettle, Stir and mix evenly; add the remaining 70kg of ethylene glycol into the mixing kettle, stir and mix evenly, pack into barrels after cooling, and seal and store to prepare the industrial water-saving agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com