Polymerizable flame retardant resin

A technology of flame retardant resin and polyester resin, which is applied in the field of polyester composition, can solve the problems affecting the stability of flame retardant and insulation, and achieve the effects of low saturated vapor pressure, long storage period and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

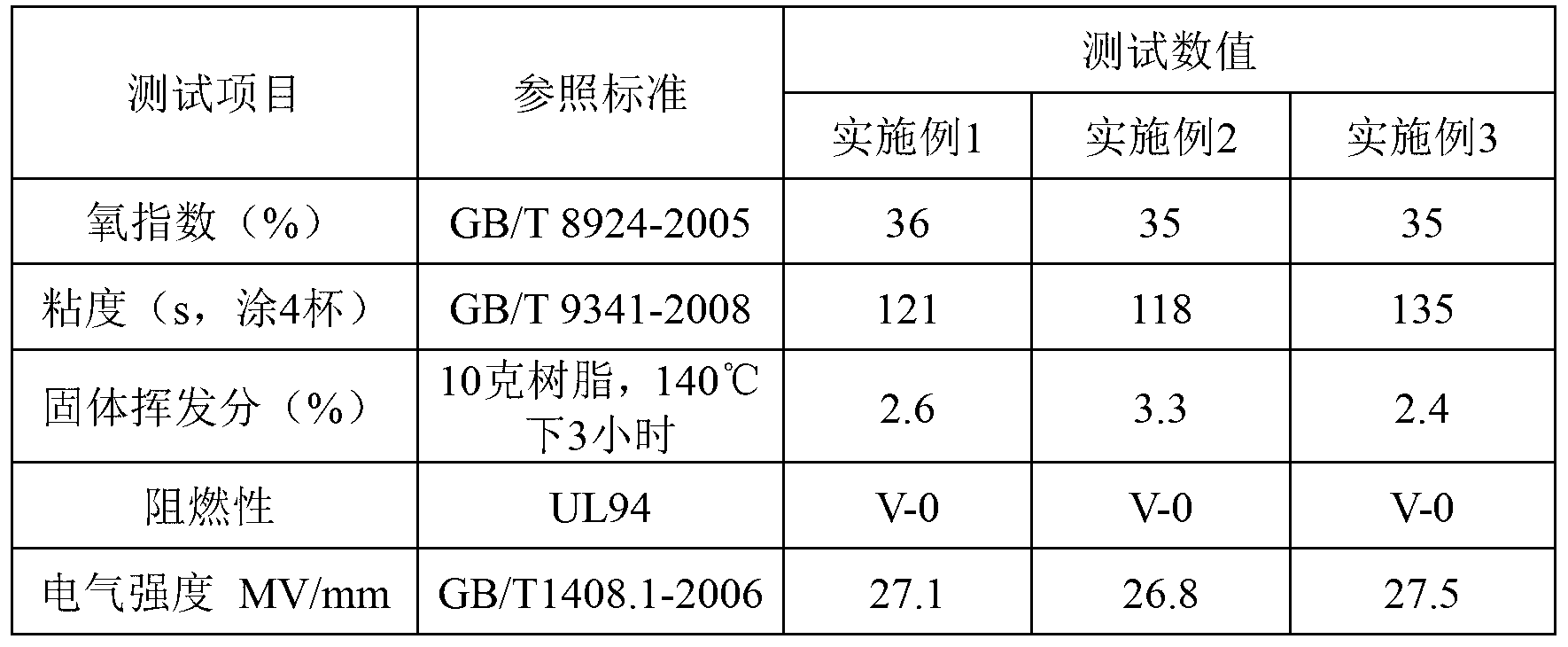

Examples

Embodiment 1

[0029] Preparation of low-molecular phosphate modified unsaturated polyester resin: react dimethyl methylphosphonate with ethylene glycol at a molar ratio of 1.3:1, under the catalysis of 0.2% catalyst acetylacetonate titanium oxide, the reaction initiation temperature 140°C, raise the temperature to 190°C and keep it warm for 3 hours, then add maleic anhydride (the molar ratio to ethylene glycol is 1:2) and react at 200°C-220°C for 4 hours, keep vacuum for 1 hour (1000Pa) to obtain low molecular phosphoric acid Ester-modified unsaturated polyester, adding 0.1w / w% of polymerization inhibitor, and a diluent made of neopentyl glycol dimethacrylate and diallyl phthalate in a weight ratio of 1:1 to Viscosity 100s (paint 4 cups), to get low molecular phosphate modified unsaturated polyester resin. After testing, the oxygen index (GB / T8924-2005) of unsaturated polyester resin after curing is 40.

[0030] Preparation of polymerizable flame retardant resin: by weight, 4.6 parts of ph...

Embodiment 2

[0032] Preparation of low-molecular phosphate modified unsaturated polyester resin: react diethyl phosphite and diethylene glycol at a molar ratio of 1.3:1, under the catalysis of 0.2% catalyst acetylacetonate titanium oxide, the reaction initiation temperature is 140 ℃, raise the temperature to 190℃ and keep it warm for 3 hours, then add maleic anhydride (the molar ratio to diethylene glycol is 1:2) and react at 200℃-220℃ for 4 hours, keep the vacuum for 1 hour (1000Pa) to obtain low molecular phosphoric acid Ester-modified unsaturated polyester, adding 0.1w / w% of polymerization inhibitor, and a diluent made of neopentyl glycol dimethacrylate and diallyl phthalate in a weight ratio of 1:1 to The viscosity is about 110s (4 cups of coating), and the low molecular phosphate modified unsaturated polyester resin is obtained. After testing, the oxygen index (GB / T8924-2005) of unsaturated polyester resin after curing is 38.

[0033] Preparation of polymerizable flame retardant resi...

Embodiment 3

[0035] The preparation of low-molecular phosphoric acid ester modified unsaturated polyester resin: same as embodiment 2.

[0036] Preparation of polymerizable flame-retardant resin: by weight, 4.4 parts of phosphorus-containing epoxy resin, 2.2 parts of nitrogen-containing epoxy resin, 18 parts of bisphenol A epoxy resin and 48.5 parts of unsaturated polyester resin in Example 2 were combined Mix, then add 10 parts of diluent, 15.4 parts of hydrogenated methyl endomethylene tetrahydrophthalic anhydride, 1 part of dicumyl peroxide and 0.5 part of acetylacetonate to cure to obtain a polymerizable flame retardant resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com