Method for preparing nano-scale molybdenum powder

A nano-scale, molybdenum powder technology, applied in the field of ultrafine metal powder preparation, can solve the problems of low process yield, unsuitable for large-scale production, and high production cost, and achieves short process flow, difficult grain growth, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The nanoscale molybdenum powder preparation method of the present invention adopts the nanoscale ammonium octamolybdate having a particle diameter less than 100nm as a raw material, and adopts two reduction methods to prepare, and the preparation process includes the following steps:

[0020] (1) Spread the raw materials evenly in the burning boat, with a thickness of 6-13mm;

[0021] (2) For the first reverse reduction treatment, the reduction condition is furnace temperature 380-560°C, the reducing agent is hydrogen produced by water electrolysis, and the hydrogen flow rate is 20-50m 3 / h, dew point ≤ -30°C, the residence time of raw materials in the furnace is 90-180min;

[0022] (3) For the second reverse reduction treatment, the reduction condition is furnace temperature 600-750°C, the reducing agent is hydrogen produced by water electrolysis, and the hydrogen flow rate is 60-100m 3 / h, dew point ≤ -30°C, raw material residence time in the furnace is 120-180min. ...

Embodiment

[0024] This embodiment is carried out in a 160KW four-tube furnace, and the raw material used is nano-scale ammonium octamolybdate, and its quality analysis test results are shown in Table 1. The burning boat used is made of molybdenum, the size is 390×280×40mm, and the charging thickness is between 10.5 and 12.5mm. The hydrogen produced by water electrolysis is used as the reverse reducing agent, the dew point is ≤ -30°C, the reduction reaction is carried out in a closed environment, and the recovered hydrogen is recycled after being deoxygenated and dried.

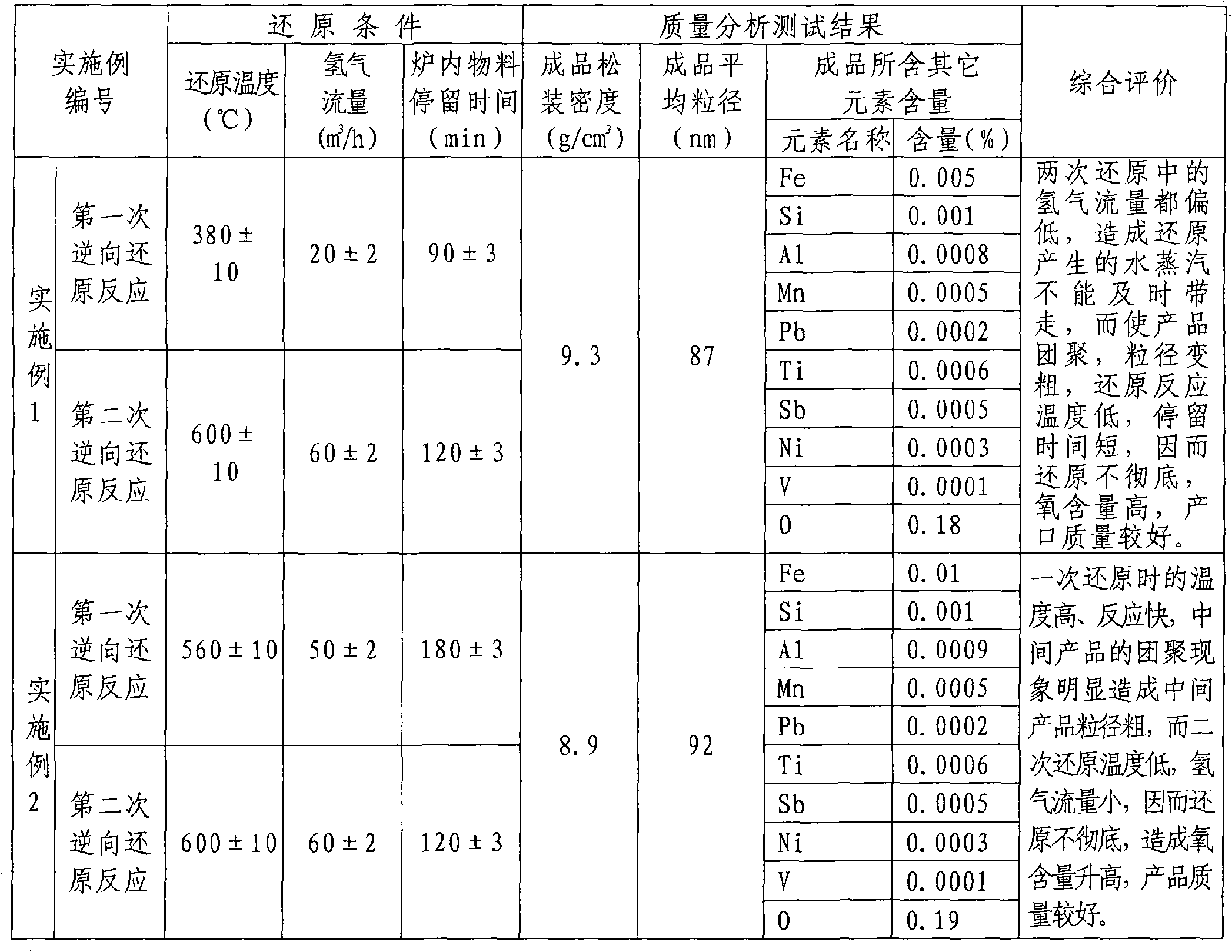

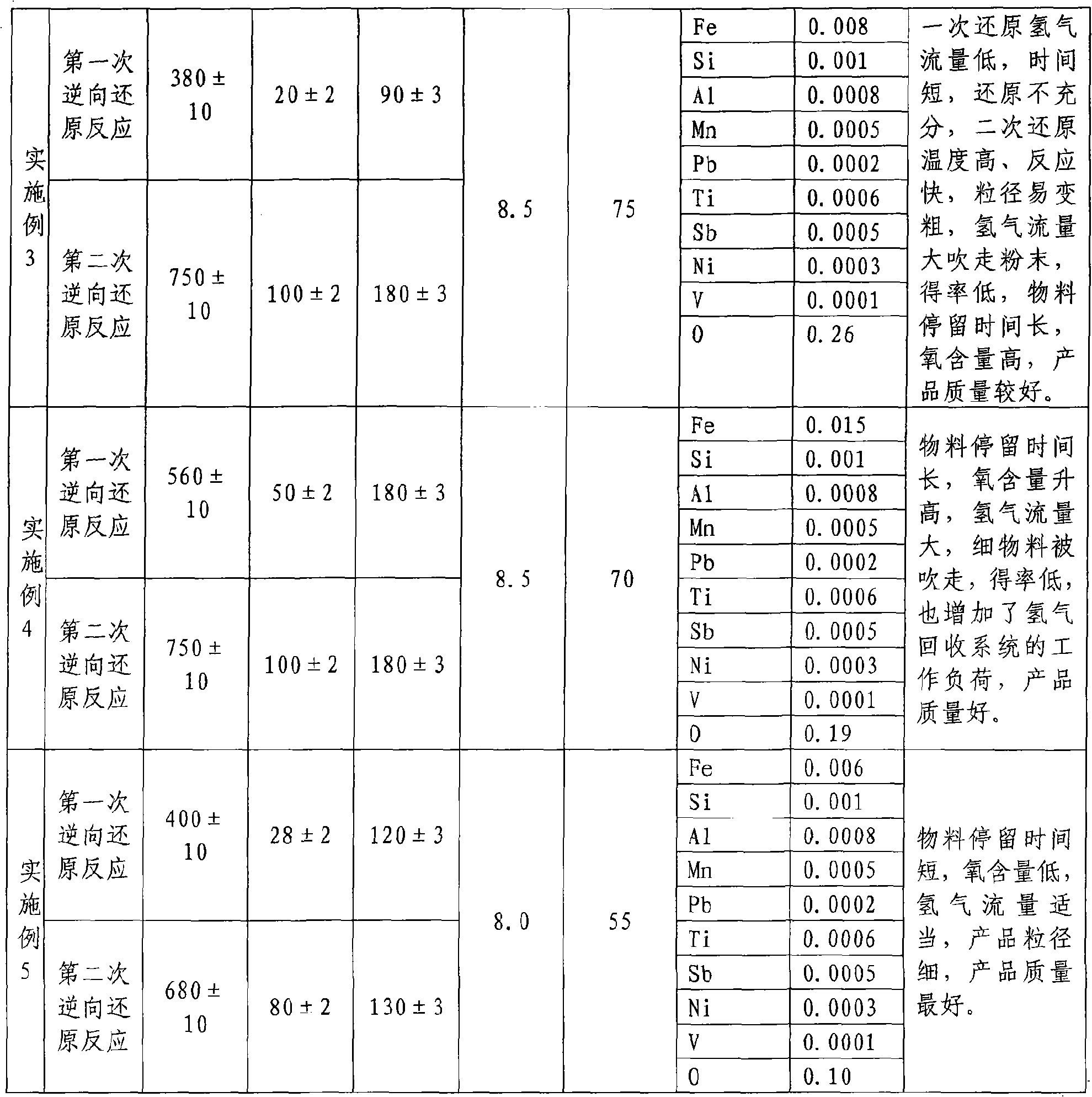

[0025] According to the above-mentioned technological process, the relevant reduction conditions were appropriately changed, and the embodiment operations were carried out in batches. The quality analysis and test results of the finished products were shown in Table 2 below.

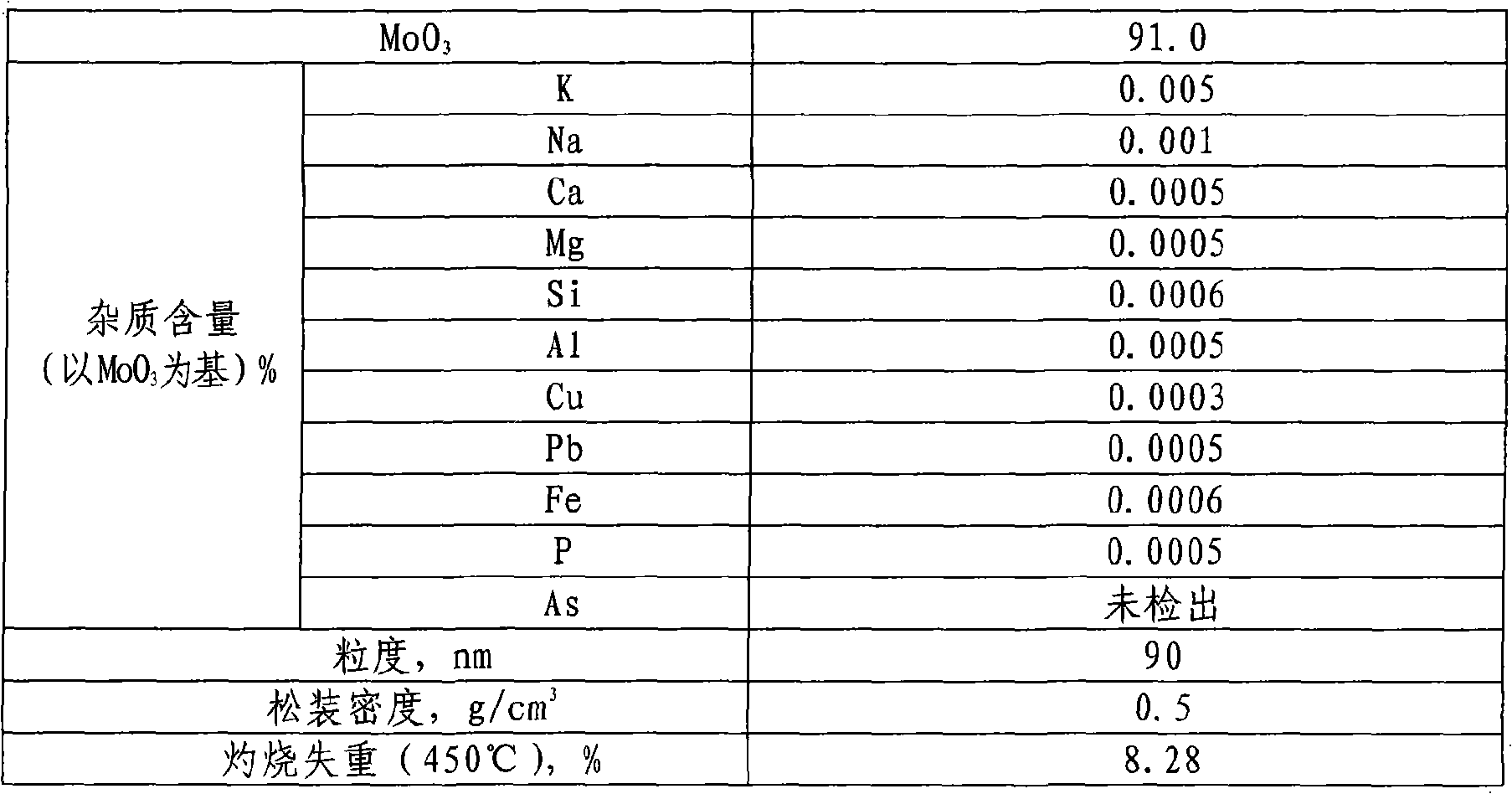

[0026] Table 1: Analysis and test results of raw materials (nano-scale ammonium octamolybdate)

[0027]

[0028] Table 2: The quality analysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com