Low-pressure liquefied gas thrust generating method for spacecraft

A generation method and technology of liquefied gas, which is applied in the direction of aerospace vehicle propulsion system devices, aerospace vehicle guidance devices, etc., can solve the problems of large occupied volume, low integration of thrust generation modules, unstable thrust, etc., and achieve the occupied volume The effect of small size, shortening the development cycle and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

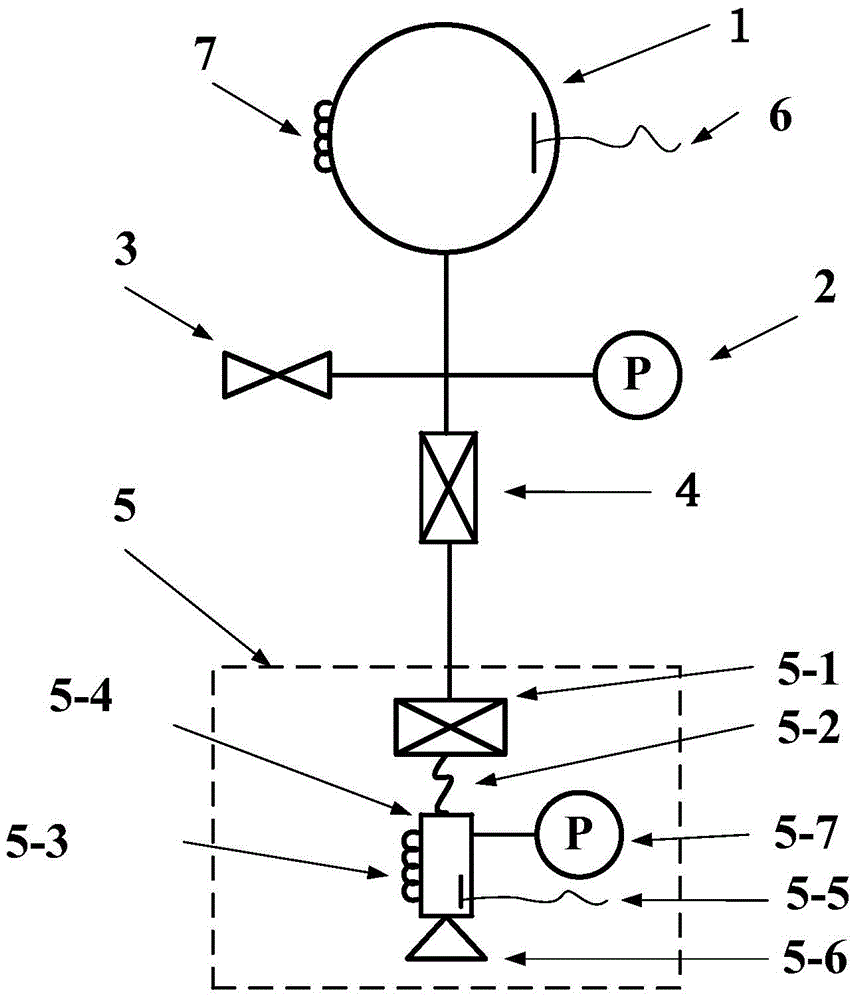

[0036] Take butane as the propellant as an example to describe the thrust generation process of low-pressure liquefied gas,

[0037] Step (1), inject liquid butane into the storage tank 1 through the addition and discharge valve 3 for storage; afterwards, it can be directly loaded.

[0038] Step (2), the storage tank 1 is heated by the first heater 7. When the first temperature sensor 6 measures that the gas temperature in the storage tank 1 reaches 40°C, the self-locking valve 4 is opened to make the liquid butane in the storage tank 1 Enter the inlet of solenoid valve 5-1.

[0039] Step (3): Heat the thrust chamber 5-4 by the second heater 5-3, and turn off the second heater 5-3 when the second temperature sensor 5-3 measures that the temperature of the thrust chamber 5-4 reaches 200°C; Open the solenoid valve 5-1, make the liquid butane enter the thrust chamber 5-4 through the capillary 5-2, the flow rate is 0.1~0.2g / s, the high temperature gas generated in the thrust chamber 5-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com