Hydrogel flexible strain sensor and preparation method thereof

A strain sensor, hydrogel flexible technology, applied in the application field of equipment, can solve the problem of sensor performance degradation, and achieve the effect of excellent performance, low cost and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

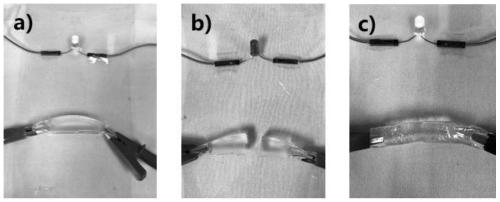

[0055] Fabrication of hydrogel flexible strain sensors:

[0056] (1) Dissolve 7.5g of acrylamide, 1.5g of carrageenan, 0.005g of N,N'-methylenebisacrylamide, and 0.09g of potassium chloride in 41mL of deionized water, and perform oil bath magnetic Stir for 5 hours to synthesize the first network of carrageenan;

[0057] (2) Continue stirring after stopping heating, when the temperature drops to 70°C, add 0.024g ammonium persulfate and stir for 1 minute;

[0058] (3) Pour the solution into a Petri dish, cover it with aluminum foil, place it in an oven, and bake it at 90°C for 1 hour to polymerize to form a second polyacrylamide network. Storing for 1 hour at lower temperature, the K-type carrageenan double-network hydrogel was obtained;

[0059] (4) Clean and dry the K-type carrageenan double network hydrogel, install conductive electrodes, and package it into a flexible strain sensor.

Embodiment 2

[0061] Fabrication of hydrogel flexible strain sensors:

[0062] (1) Dissolve 7.5g of acrylamide, 1.5g of carrageenan, 0.005g of N,N'-methylenebisacrylamide, and 0.09g of potassium chloride in 41mL of deionized water, and perform oil bath magnetic Stir for 5 hours to synthesize the first network of carrageenan;

[0063] (2) Continue stirring after stopping heating, when the temperature drops to 70°C, add 0.024g ammonium persulfate and stir for 1 minute;

[0064] (3) Pour the solution into a Petri dish, cover it with aluminum foil, place it in an oven, and bake it at 90°C for 1 hour to polymerize to form a second polyacrylamide network. Storing for 1 hour at lower temperature, the K-type carrageenan double-network hydrogel was obtained;

[0065] (4) Soak the K-type carrageenan double network hydrogel prepared above in pure ethylene glycol solution for 5 minutes and then take it out;

[0066] (5) Clean and dry the K-type carrageenan double-network hydrogel, install conductive...

Embodiment 3

[0068] Fabrication of hydrogel flexible strain sensors:

[0069] (1) Dissolve 7.5g of acrylamide, 1.5g of carrageenan, 0.005g of N,N'-methylenebisacrylamide, and 0.09g of potassium chloride in 41mL of deionized water, and perform oil bath magnetic Stir for 5 hours to synthesize the first network of carrageenan;

[0070] (2) Continue stirring after stopping heating, when the temperature drops to 70°C, add 0.024g ammonium persulfate and stir for 1 minute;

[0071] (3) Pour the solution into a Petri dish, cover it with aluminum foil, place it in an oven, and bake it at 90°C for 1 hour to polymerize to form a second polyacrylamide network. Storing for 1 hour at lower temperature, the K-type carrageenan double-network hydrogel was obtained;

[0072] (4) Soak the K-type carrageenan double network hydrogel prepared above in pure ethylene glycol solution for 8 minutes and then take it out;

[0073] (5) Clean and dry the K-type carrageenan double-network hydrogel, install conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com