Building ground anti-crack construction process

A construction technology and ground technology, which is applied in the direction of buildings, building structures, floors, etc., can solve the problems of easy cracking on the ground, and achieve the effect of improving crack resistance, not easy to damage, and improving crack resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

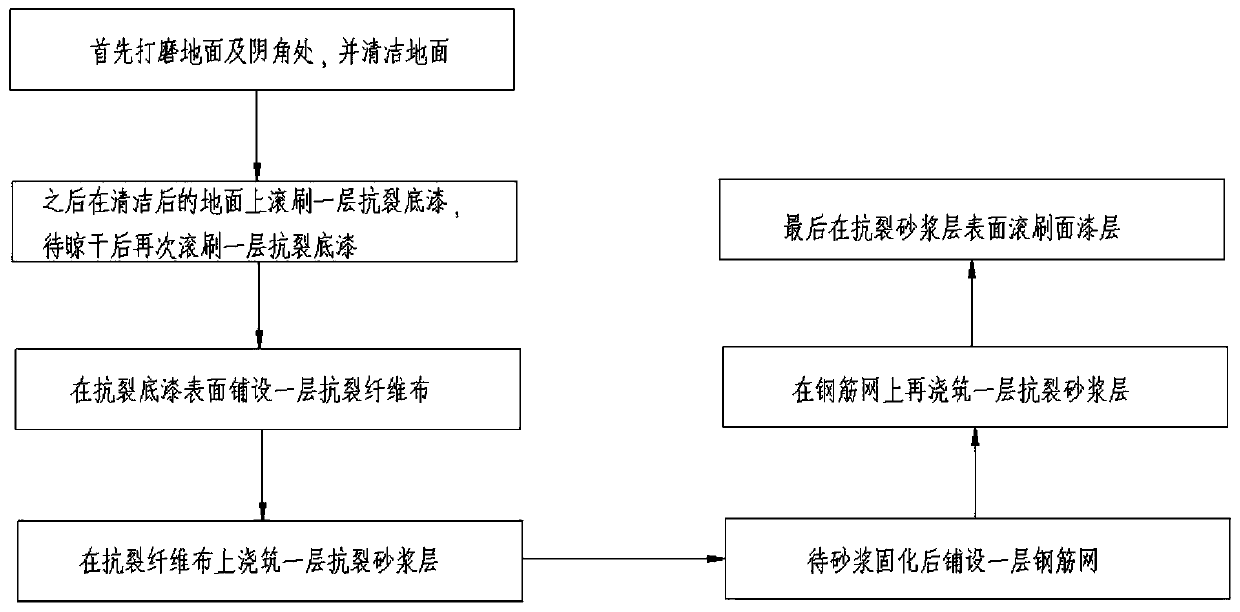

[0024] see figure 1 , the present invention provides the following technical scheme: a kind of anti-cracking construction technology for building ground, comprising the following steps:

[0025] A. First polish the ground and the corners, and clean the ground;

[0026] B. After that, roll a layer of anti-crack primer on the cleaned ground, and then roll another layer of anti-crack primer after drying;

[0027] C. Lay a layer of anti-crack fiber cloth on the surface of the anti-crack primer;

[0028] D. Pouring a layer of anti-crack mortar layer on the anti-crack fiber cloth;

[0029] E. Lay a layer of steel mesh after the mortar is cured;

[0030] F. Pour another layer of anti-cracking mortar layer on the steel mesh;

[0031] G. Finally, brush the topcoat layer on the surface of the anti-cracking mortar layer.

[0032] In the present embodiment, in the step B, the anti-cracking primer is made of 30% castor oil short oil alkyd resin, 30% terpolymer resin, 20% calcium zirco...

Embodiment 2

[0037] A building ground anti-cracking construction process, comprising the following steps:

[0038] A. First polish the ground and the corners, and clean the ground;

[0039] B. After that, roll a layer of anti-crack primer on the cleaned ground, and then roll another layer of anti-crack primer after drying;

[0040] C. Lay a layer of anti-crack fiber cloth on the surface of the anti-crack primer;

[0041] D. Pouring a layer of anti-crack mortar layer on the anti-crack fiber cloth;

[0042] E. Lay a layer of steel mesh after the mortar is cured;

[0043] F. Pour another layer of anti-cracking mortar layer on the steel mesh;

[0044] G. Finally, brush the topcoat layer on the surface of the anti-cracking mortar layer.

[0045] In the present embodiment, in the step B, the anti-cracking primer is made of 30% castor oil short oil alkyd resin, 30% terpolymer resin, 20% calcium zirconate, 5% barium zirconate, 5% zirconium nitride, 5% polydimethylsiloxane, 5% nano-titanium di...

Embodiment 3

[0050] A building ground anti-cracking construction process, comprising the following steps:

[0051] A. First polish the ground and the corners, and clean the ground;

[0052] B. After that, roll a layer of anti-crack primer on the cleaned ground, and then roll another layer of anti-crack primer after drying;

[0053] C. Lay a layer of anti-crack fiber cloth on the surface of the anti-crack primer;

[0054] D. Pouring a layer of anti-crack mortar layer on the anti-crack fiber cloth;

[0055] E. Lay a layer of steel mesh after the mortar is cured;

[0056] F. Pour another layer of anti-cracking mortar layer on the steel mesh;

[0057] G. Finally, brush the topcoat layer on the surface of the anti-cracking mortar layer.

[0058] In the present embodiment, in the step B, the anti-cracking primer is made of 30% castor oil short oil alkyd resin, 30% terpolymer resin, 20% calcium zirconate, 5% barium zirconate, 5% zirconium nitride, 5% polydimethylsiloxane, 5% nano-titanium di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com