A kind of protein foam fire extinguishing agent and preparation method thereof

A foam fire extinguishing agent and protein technology, applied in fire protection equipment and other directions, can solve the problems of insufficient durability of the foam floating layer, weak stability of the foam floating layer, poor frost resistance, etc., achieving strong oil pollution resistance and long anti-burning time. , long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

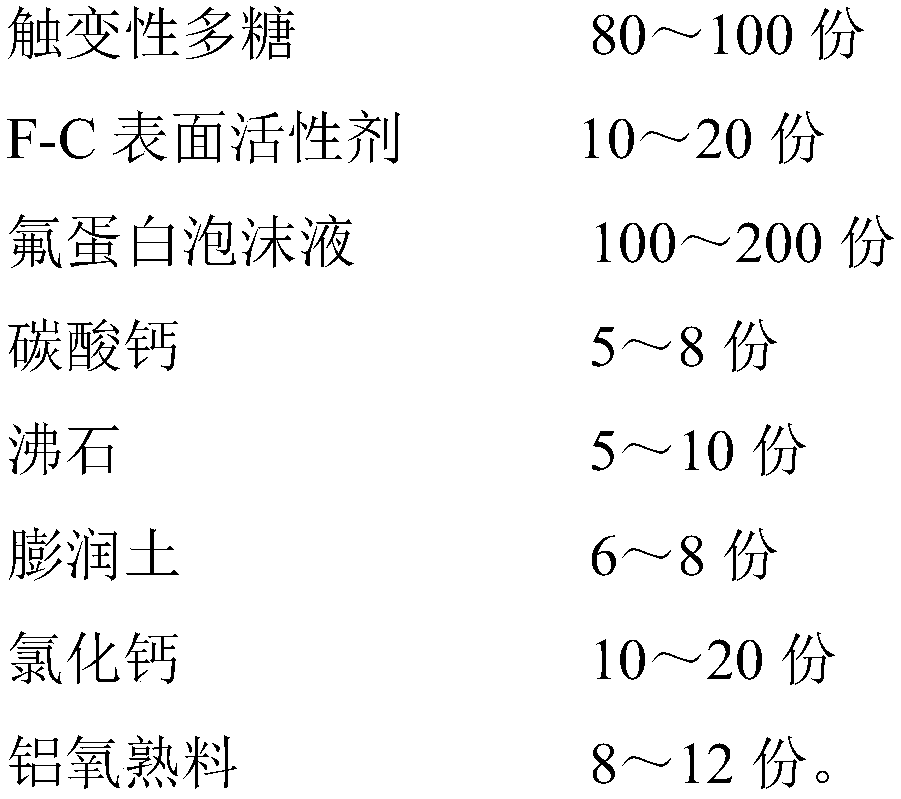

[0021] A protein foam fire extinguishing agent is made of the following component raw materials in parts by weight,

[0022]

[0023] A preparation method of protein foam fire extinguishing agent, comprising the following steps,

[0024] 1) Thoroughly mix the thixotropic polysaccharide, F-C surfactant and fluoroprotein foam solution at a temperature of 50°C;

[0025] 2) Grinding calcium carbonate, zeolite, bentonite, calcium chloride and alumina clinker respectively, and then screening with a 20-mesh screen, the screening is completed or mixed;

[0026] 3) fully mix the mixture obtained in step 1) and step 2) at a temperature of 80°C;

[0027] 4) Fill the mixture obtained in step 3) into a compression tank.

Embodiment 2

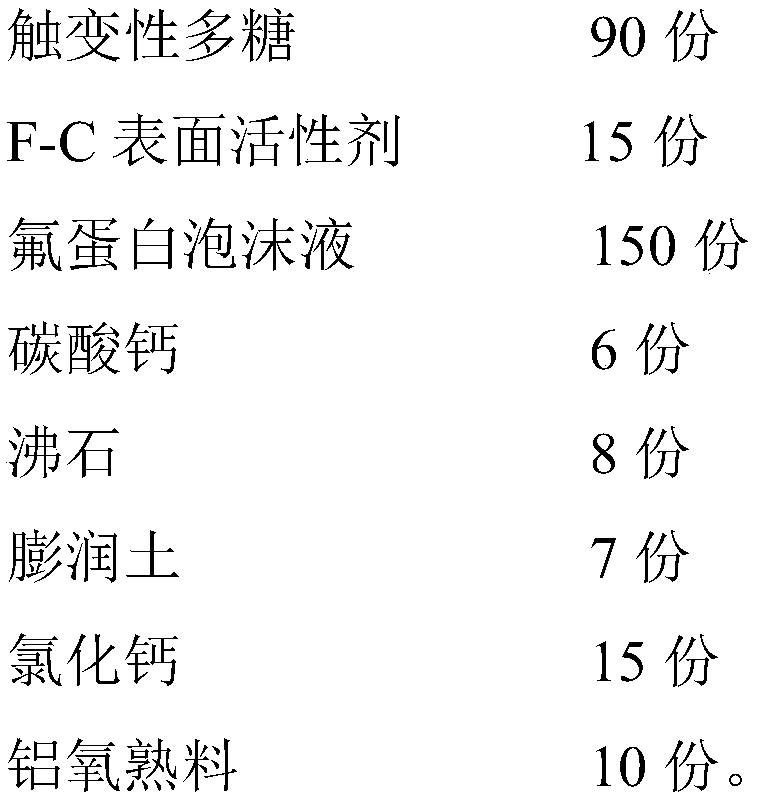

[0029] A protein foam fire extinguishing agent is made of the following component raw materials in parts by weight,

[0030]

[0031]

[0032] A preparation method of protein foam fire extinguishing agent, comprising the following steps,

[0033] 1) Thoroughly mix the thixotropic polysaccharide, F-C surfactant and fluoroprotein foam at a temperature of 55°C;

[0034] 2) Grinding calcium carbonate, zeolite, bentonite, calcium chloride and alumina clinker respectively, and then screening with a 40-mesh screen, the screening is completed or mixed;

[0035] 3) Fully mix the mixture obtained in step 1) and step 2) at a temperature of 90°C;

[0036] 4) Fill the mixture obtained in step 3) into a compression tank.

Embodiment 3

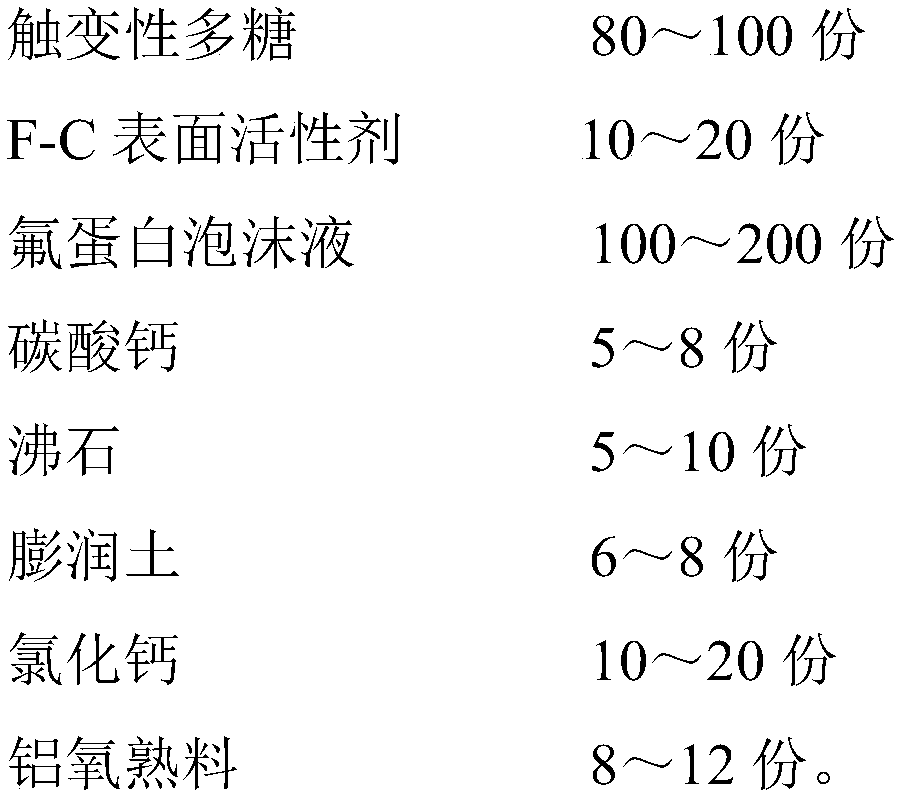

[0038] A protein foam fire extinguishing agent is made of the following component raw materials in parts by weight,

[0039]

[0040] A preparation method of protein foam fire extinguishing agent, comprising the following steps,

[0041] 1) Fully mix the thixotropic polysaccharide, F-C surfactant and fluoroprotein foam at a temperature of 60°C;

[0042] 2) Grinding calcium carbonate, zeolite, bentonite, calcium chloride and alumina clinker respectively, and then screening with a 20-60 mesh screen, the screening is completed or mixed;

[0043] 3) Fully mix the mixture obtained in step 1) and step 2) at a temperature of 100°C;

[0044] 4) Fill the mixture obtained in step 3) into a compression tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com