Double-layer super-hydrophobic material and preparation method thereof

A super-hydrophobic, double-layer technology, applied in the coating process of metal materials, coatings, etc., can solve the problems of reducing surface energy, corrosion, growth, etc., to achieve improved roughness, obvious corrosion resistance, and slow corrosion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

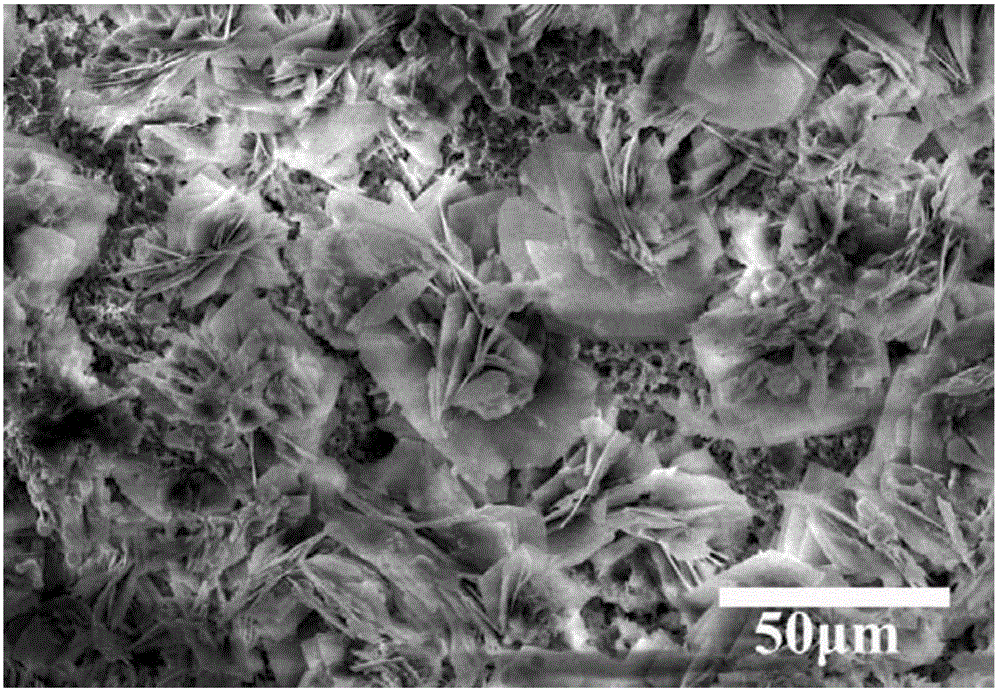

[0033] The material of the present invention is a super-hydrophobic film with two layers of micro-nano multi-level structure coated on an alloy substrate. The composition of the super-hydrophobic film is a long-chain fatty acid salt; the first super-hydrophobic layer above the substrate is a micro-nano sheet layer The network crystal structure built, the second layer of super-hydrophobic crystal micro-nano non-uniform distribution sheet structure.

[0034] The preparation method of this material is:

[0035] (1) AZ31 magnesium alloy was selected to be polished with sandpaper and soaked in absolute ethanol to ultrasonically clean the oxide film and oil stain on the surface of the alloy, cleaned with deionized water, and dried to obtain material A;

[0036] (2) according to 0.5-10mL / cm 2 Soak material A into a mixture of equal volumes of 0.01mol / L stearic acid ethanol solution and 0.01mol / L nickel sulfate aqueous solution, heat at 140°C for 7 hours; take out and dry after cooli...

Embodiment 2

[0040] The material preparation method of this example is basically the same as that of Example 1, except that the heating temperature of the second hydrothermal heating is 90°C.

[0041] The material obtained by this method has a special double-layer micro-nano structure, the bottom layer is a network structure built by micro-nano sheets, and the upper layer is a complementary micro-nano three-dimensional sheet structure.

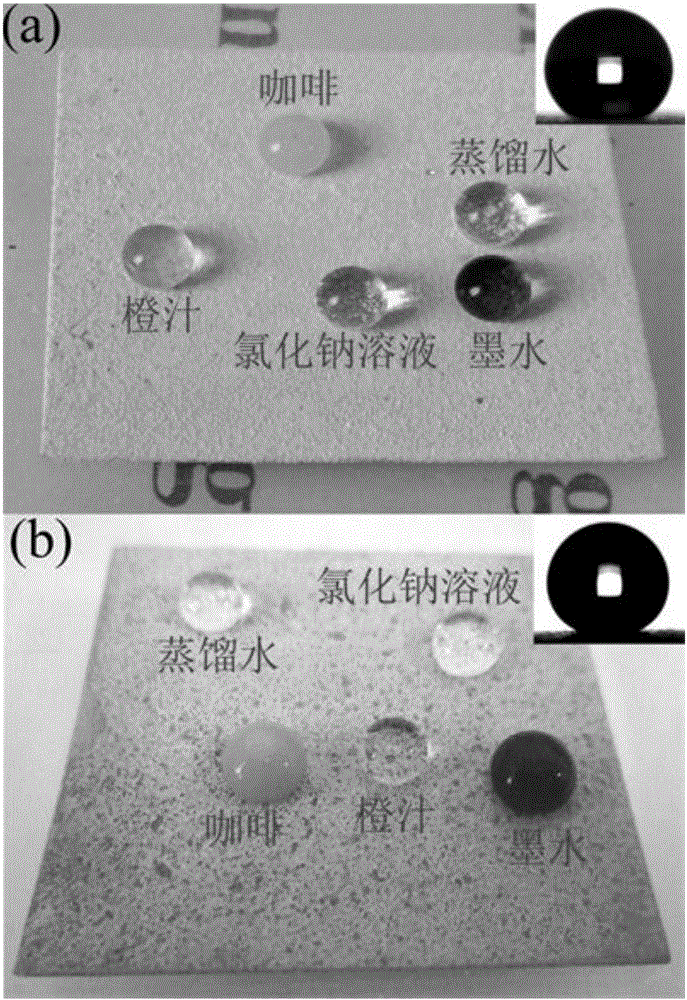

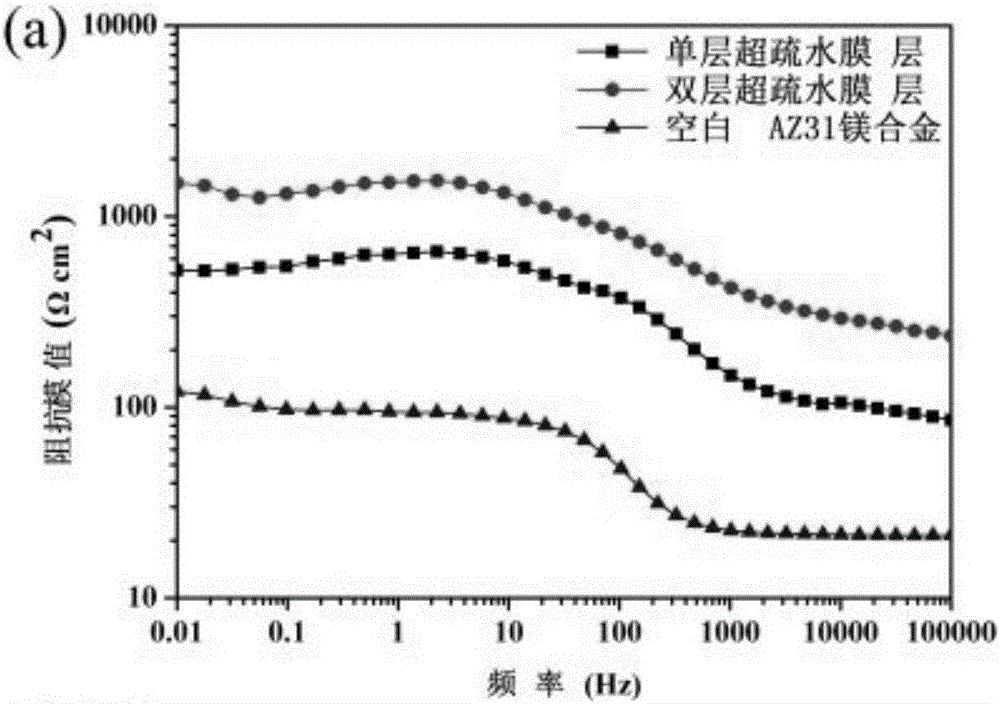

[0042] The material synthesized by the two-step hydrothermal method of the method has excellent hydrophobic properties, the surface contact angle reaches 152°, does not adhere to various complex liquids, and has good self-cleaning properties and antifouling properties. The material has good corrosion resistance, and after soaking in 3.5wt.% NaCl solution for 24 hours, the impedance modulus can still reach 800Ωcm 2 .

Embodiment 3

[0044] The material preparation method of this example is basically the same as that of Example 1, except that the heating temperature of the second hydrothermal heating is 120°C.

[0045] The material obtained by this method has a special double-layer micro-nano structure, the bottom layer is a network structure built by micro-nano sheets, and the upper layer is a sheet-like structure with a relatively uniform micro-nano distribution complementary to it.

[0046]The surface contact angle of the double-layer superhydrophobic material reaches 151°, which also achieves the double-layer superhydrophobic effect; it has self-cleaning, anti-fouling and corrosion resistance properties, and after soaking in 3.5wt.% NaCl solution for 24 hours, the impedance modulus can still reach 700Ωcm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface contact angle | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com