Corrosion-resistant electric power steel pipe pole

An electric steel pipe, corrosion-resistant technology, applied in the direction of anti-corrosion paint, paint containing biocide, coating, etc., can solve the problems of low strength of the anti-corrosion layer on the outer surface of the root, economic loss, short service life, etc., to avoid steel pipe The strength of the tower structure is reduced, the corrosion resistance is good, and the effect of wear resistance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

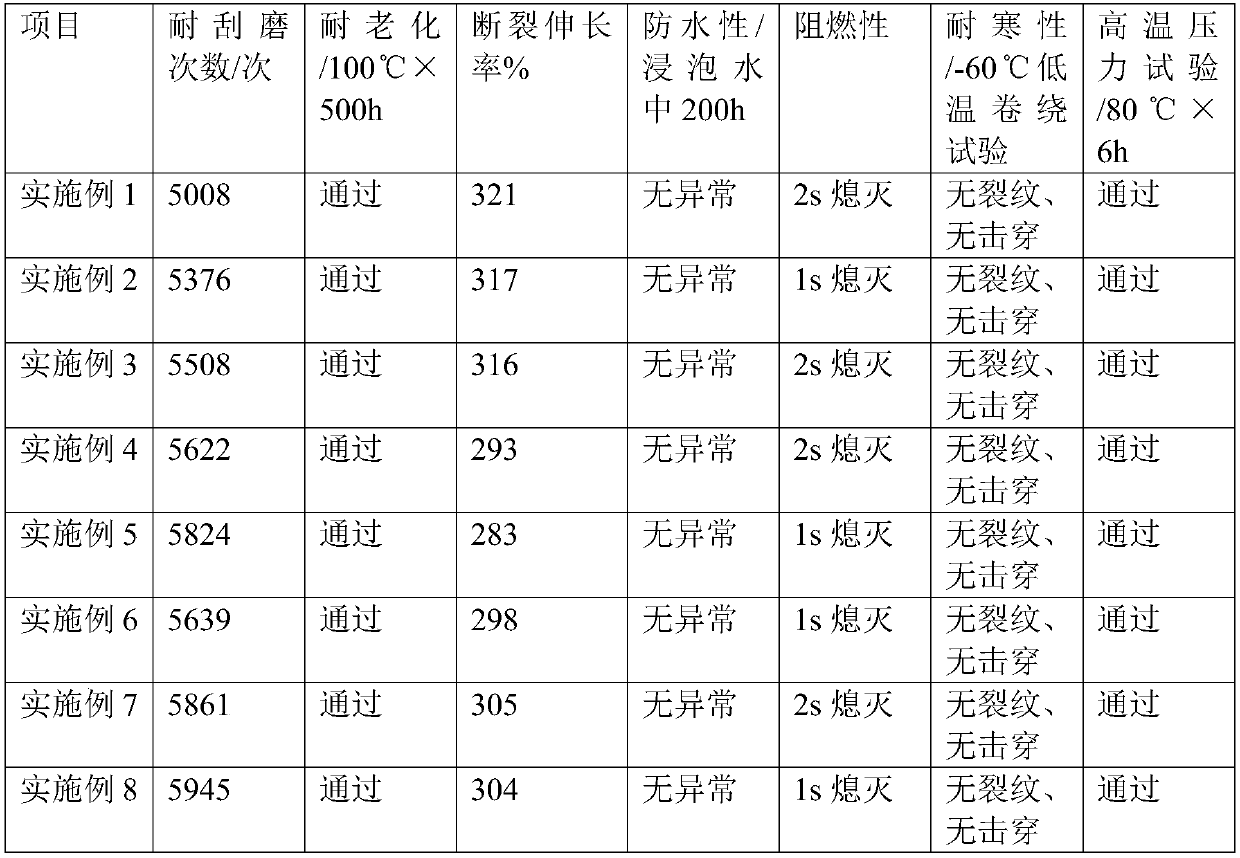

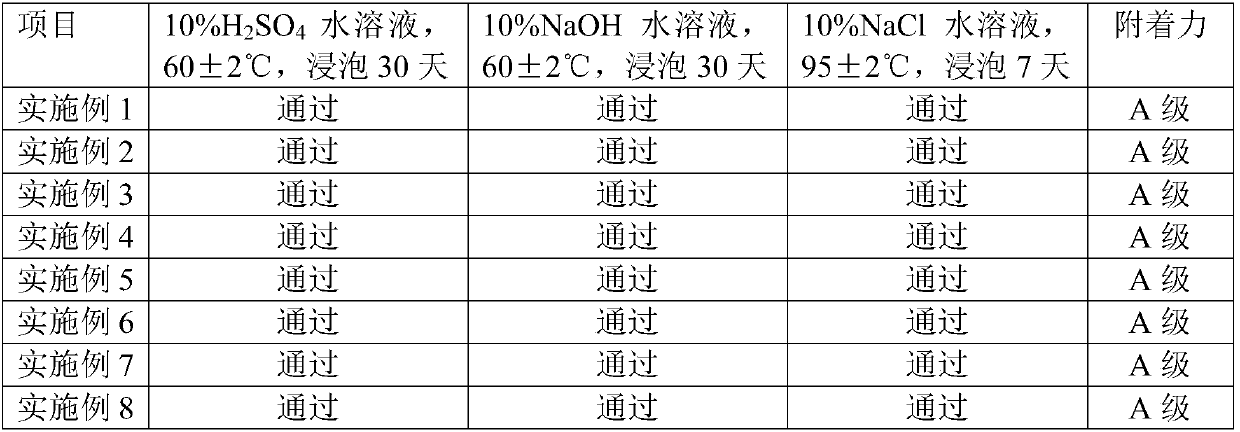

Examples

Embodiment 1

[0025] A corrosion-resistant electric steel pipe tower pole, the raw material composition of the protective layer includes, in parts by weight, 30 parts of hydroxyethyl cellulose aqueous solution, 0.1 part of glycerin, 2.85 parts of propylene glycol, 5 parts of propylene glycol butyl ether, and pure acrylic silicon emulsion 60 parts, 0.05 parts of sodium trichlorophenolate, 0.2 parts of magnesium hydroxide, 0.2 parts of zinc dimethyl dithiocarbamate, 0.2 parts of castor bean carbonized powder, 0.5 parts of hydroxypropyl starch ether, ethylene bisstearamide 0.4 part, magnesium aluminum silicate 0.1 part, corn pollen 0.1 part, cyclodextrin 0.1 part, adjust the pH value to 8.

Embodiment 2

[0027] A corrosion-resistant electric steel pipe tower rod, the raw material composition of the protective layer includes, in parts by weight, 26 parts of hydroxyethyl cellulose aqueous solution, 0.15 parts of glycerin, 2.5 parts of propylene glycol, 4.5 parts of propylene glycol butyl ether, pure acrylic silicon emulsion 65 parts, 0.1 parts of sodium trichlorophenolate, 0.15 parts of magnesium hydroxide, 0.15 parts of zinc dimethyl dithiocarbamate, 0.1 parts of castor bean carbonized powder, 0.5 parts of hydroxypropyl starch ether, ethylene bisstearamide 0.35 parts, 0.05 parts of magnesium aluminum silicate, 0.1 parts of corn pollen, 0.05 parts of cyclodextrin, 5 parts of ammonium polyphosphate, 1 part of melamine, 0.5 parts of pentaerythritol, 0.3 parts of expanded graphite, adjust the pH value to 8.5.

Embodiment 3

[0029] A corrosion-resistant electric steel pipe tower rod, the raw material composition of the protective layer includes, in parts by weight, 20 parts of hydroxyethyl cellulose aqueous solution, 0.2 parts of glycerin, 3 parts of propylene glycol, 5 parts of propylene glycol butyl ether, pure acrylic silicon emulsion 70 parts, 0.05 parts of sodium trichlorophenolate, 0.2 parts of magnesium hydroxide, 0.2 parts of zinc dimethyl dithiocarbamate, 0.2 parts of carbonized castor bean powder, 0.4 parts of hydroxypropyl starch ether, ethylene bisstearamide 0.3 part, 0.1 part of magnesium aluminum silicate, 0.05 part of corn pollen, 0.1 part of cyclodextrin, adjust the pH value to 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com