Universal vinyl acetate-vinyl versatate-acrylate copolymer emulsion interface agent and preparation method thereof

A copolymer emulsion, a general-purpose technology, applied in the field of architectural decoration coatings, can solve the problems of poor compatibility between interface agents and cement, insufficient permeability, low wall adhesion, etc., and achieves excellent comprehensive performance, excellent thermal storage stability, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

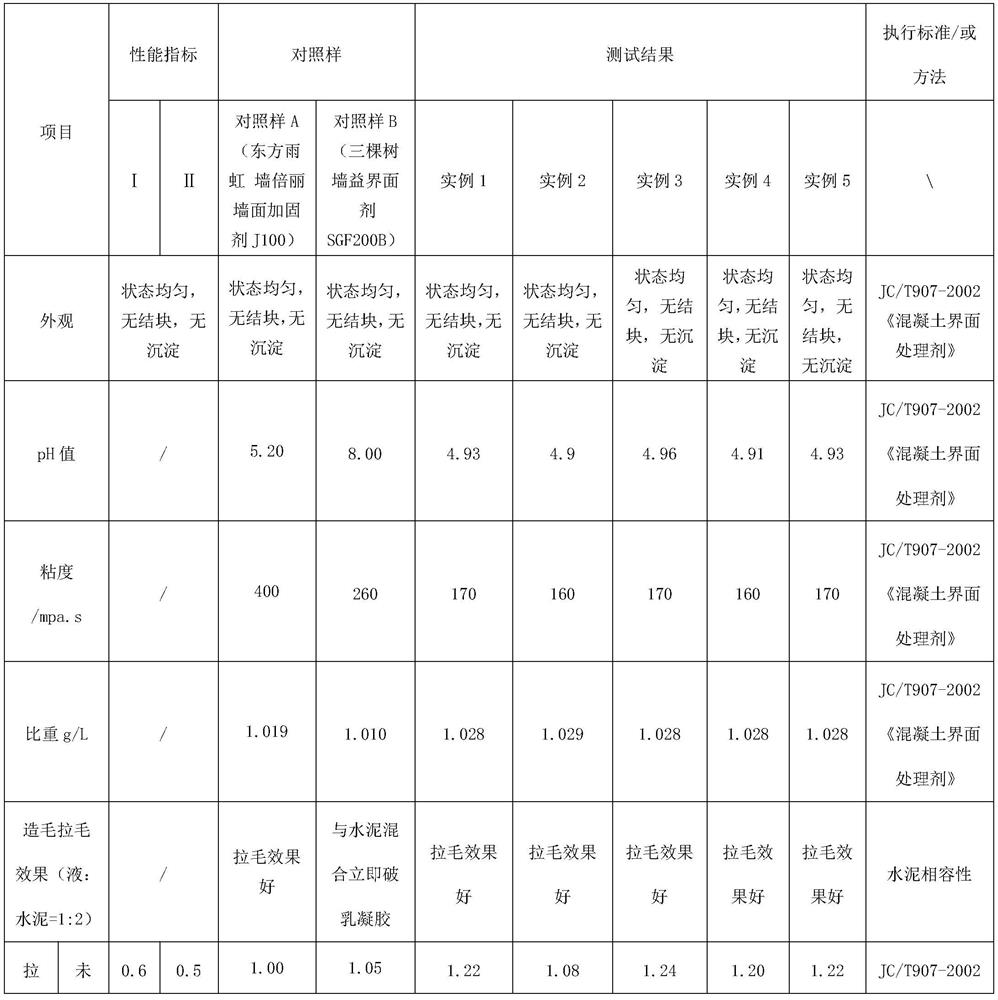

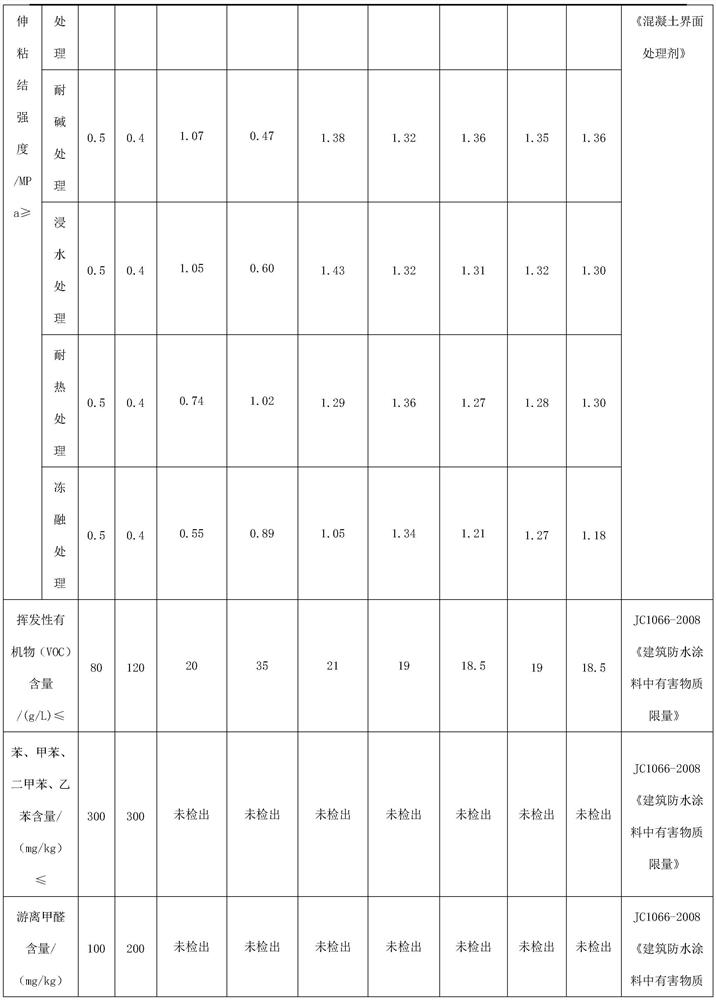

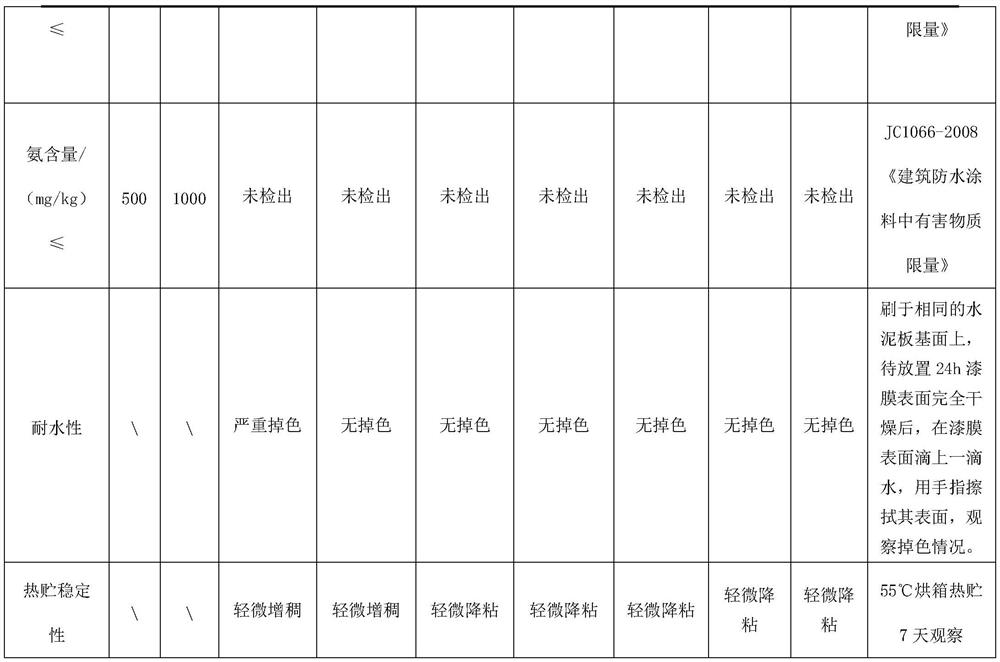

Examples

Embodiment 1

[0052] A general-purpose vinegar, tertiary, acrylic copolymer emulsion interface agent according to the present invention is mainly prepared from the following components according to the following weight and number ratios:

[0053] Mass percent concentration is 10% polyvinyl alcohol: 20 parts

[0054] Vinegar, tertiary, acrylic copolymer emulsion: 22 parts

[0055] Water: 58 parts;

[0056] Wherein, vinegar, tert-acrylic copolymer emulsion is mainly prepared from the following components according to the following ratios by weight:

[0057] Water: 49.7 parts

[0058] Polyvinyl alcohol: 2 parts

[0059] pH regulator: 1.5 parts

[0060] Mixed emulsifier: 1.0 parts

[0061] Defoamer: 0.1 parts

[0062] Mass percent concentration is 4% potassium persulfate solution: 2.5 parts

[0063] Mixed monomer: 45 parts

[0064] Diethylene glycol dibenzoate: 2.0 parts

[0065] Preservatives: 0.2 parts;

[0066] Among them, the mixed emulsifier is mainly prepared from the following ...

Embodiment 2

[0086] A general-purpose vinegar, tertiary, acrylic copolymer emulsion interface agent according to the present invention is mainly prepared from the following components according to the following weight and number ratios:

[0087] Mass percent concentration is 12% polyvinyl alcohol: 15 parts

[0088] Vinegar, tertiary, acrylic copolymer emulsion: 25 parts

[0089] Water: 60 parts;

[0090] Wherein, vinegar, tert-acrylic copolymer emulsion is mainly prepared from the following components according to the following ratios by weight:

[0091] Water: 54.3 parts

[0092] Polyvinyl alcohol: 2.5 parts

[0093] pH regulator: 1.8 parts

[0094] Mixed emulsifier: 1.3 parts

[0095] Defoamer: 0.15 parts

[0096] Mass percent concentration is 3.5% potassium persulfate solution: 3.0 parts

[0097] Mixed monomer: 40 parts

[0098] Dipropylene glycol dibenzoate: 1.5 parts

[0099] Preservatives: 0.25 parts;

[0100] Among them, the mixed emulsifier is mainly prepared from the fol...

Embodiment 3

[0120] A general-purpose vinegar, tertiary, acrylic copolymer emulsion interface agent according to the present invention is mainly prepared from the following components according to the following weight and number ratios:

[0121] Mass percent concentration is 15% polyvinyl alcohol: 10 parts

[0122] Vinegar, tertiary, acrylic copolymer emulsion: 28 parts

[0123] Water: 62 parts;

[0124] Wherein, vinegar, tert-acrylic copolymer emulsion is mainly prepared from the following components according to the following ratios by weight:

[0125] Water: 59 parts

[0126] Polyvinyl alcohol: 3 parts

[0127]pH adjuster: 2 parts

[0128] Mixed emulsifier: 1.5 parts

[0129] Defoamer: 0.2 parts

[0130] Mass percent concentration is 3.0% potassium persulfate solution: 3.5 parts

[0131] Mixed monomer: 35 parts

[0132] Diethylene glycol dibenzoate: 1 part

[0133] Preservatives: 0.3 parts;

[0134] Among them, the mixed emulsifier is mainly prepared from the following compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com