Ceramic bovine flame retardant polymer composite material and application thereof

A technology of ceramicized flame retardant and composite materials, applied in the field of refractory materials, can solve the problems of poor mechanical properties of cable materials, poor ceramic strength, and high temperature, and achieve the effects of good mechanical properties, good high temperature strength and flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

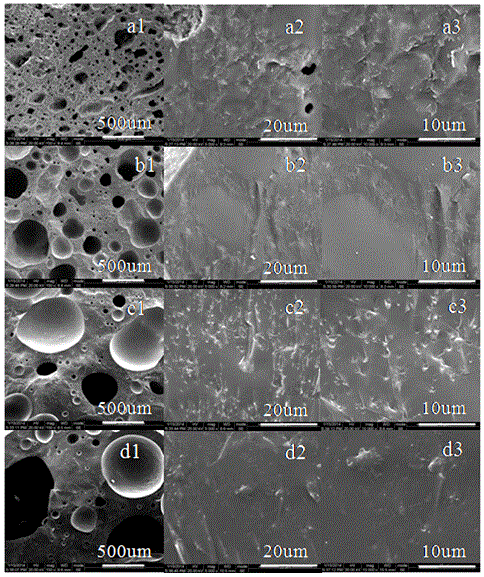

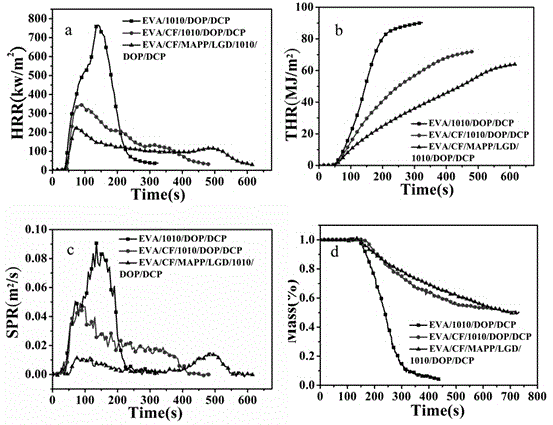

Image

Examples

Embodiment 1

[0036] Ethylene-vinyl acetate copolymer EVA: 35 parts, low softening point glass powder: 26.25 parts, E-glass fiber: 8.75 parts, flame retardant MAPP: 28 parts, LDH: 2 parts, antioxidant 1010: 1 part, Plasticizer DOP: 2.5 parts, crosslinking agent DCP: 0.05 parts.

Embodiment 2

[0038] Ethylene-vinyl acetate copolymer EVA: 35 parts, low softening point glass powder: 26.25 parts, E-glass fiber: 8.75 parts, flame retardant APP / CA (3 / 1): 28 parts, halloysite: 2 parts , antioxidant 1010: 1 part, plasticizer DOP: 2.5 parts, crosslinking agent DCP: 0.05 parts;

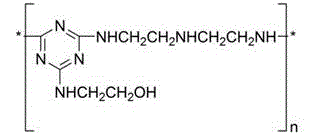

[0039] The structural formula of CA is ;n is 10.

Embodiment 3

[0041] Ethylene-vinyl acetate copolymer EVA: 35 parts, low softening point glass powder: 26.25 parts, E-glass fiber: 8.75 parts, flame retardant MCA: 28 parts, LDH: 2 parts, antioxidant 1010: 1 part, Plasticizer DNOP: 2.5 parts, crosslinking agent DCP: 0.05 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com