Method for forming multilayered patterns on aluminium composite board surface

The technology of a composite material board and a manufacturing method is applied in the process of producing decorative surface effects, decorative arts and other directions, which can solve the problems of high design difficulty and increase equipment cost, and achieve the effect of beautiful color and high corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The manufacturing method for forming a multi-layer pattern on the surface of an aluminum composite material plate disclosed by the present invention can be used to make a multi-layer metal pattern of an aluminum composite material plate, and can be applied to a notebook computer, a personal digital assistant or other devices with an aluminum composite material plate product.

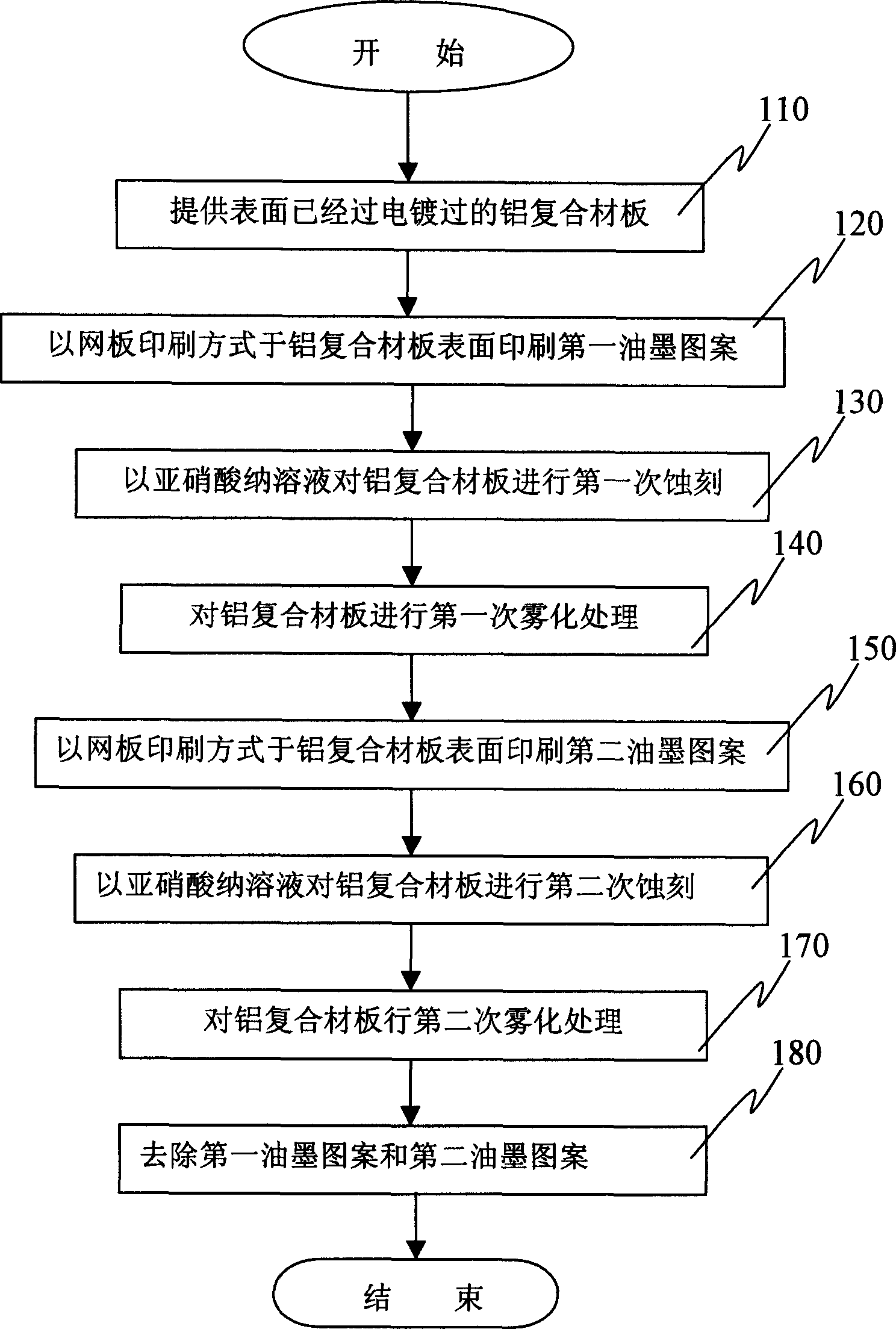

[0043] For a further description of the invention, please refer to figure 1 , which is an etching flow chart of the first embodiment of the present invention. Making patterns with different levels on the surface of the aluminum composite material board, the steps include: step 110, providing the aluminum composite material board whose surface has been electroplated; step 120, printing the first ink on the surface of the aluminum composite material board by screen printing Pattern; step 130, etching the aluminum composite material plate for the first time with sodium nitrite solution, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com