Refining method of rebamipide

A technology of rebamipide and its refining method, which is applied in the field of preparation of high-purity rebamipide, can solve problems such as difficulty in obtaining high-purity rebamipide and residual impurities, and achieve beautiful color, simple operation and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

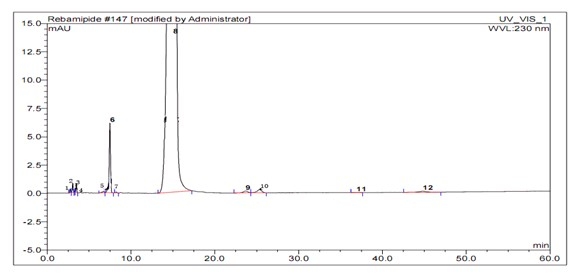

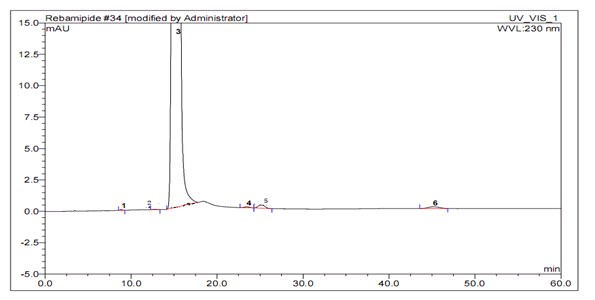

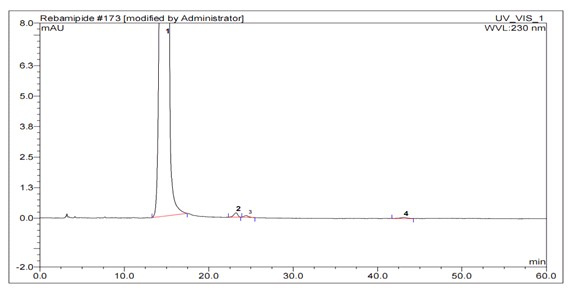

Image

Examples

Embodiment 1

[0033] 1) Preparation of crude rebamipide potassium salt

[0034] Put 370ml of methanol, 37g (0.10mol) of crude rebamipide, and 8.4g of potassium hydroxide into a 1000ml four-necked bottle in sequence, stir, and raise the temperature to 60~65°C to dissolve the solid. Add 2g of activated carbon, decolorize at this temperature for 1 hour, filter, and cool the filtrate to 0°C to crystallize. Filter, and dry the filter cake under reduced pressure at 60° C. for 8 hours to obtain 32 g of crude rebamipide potassium salt;

[0035] 2) Refined rebamipide potassium salt

[0036] Put 450ml of isopropanol and 32g of crude rebamipide potassium salt into a 500ml four-neck bottle, and heat up to 65°C to dissolve the solid. Add 2 g of activated carbon, reflux for decolorization for 1 hour, filter, and cool the filtrate to 0°C for crystallization. Filter, and dry the filter cake under reduced pressure at 60°C to obtain 29 g of refined rebamipide potassium salt;

[0037] 3) High-purity rebam...

Embodiment 2

[0040] 1) Preparation of crude product of rebamipide sodium salt

[0041] Put 550ml of methanol, 37g (0.10mol) of crude rebamipide, and 4.5g (0.143mol) of sodium hydroxide into a 1000ml four-necked bottle in sequence, stir, and raise the temperature to 75-80°C to dissolve the solid. Add 2g of activated carbon, decolorize at this temperature for 1 hour, filter, and cool the filtrate to 0°C to crystallize. Filter, and dry the filter cake under reduced pressure at 60°C to obtain 30 g of crude rebamipide sodium salt;

[0042] 2) Refined rebamipide sodium salt

[0043] Put 240ml of isopropanol, 120ml of ethyl acetate, and 30g of crude rebamipide sodium salt into a 500ml four-necked bottle, and raise the temperature to 75~80°C to dissolve the solid. Add 2 g of activated carbon, reflux for decolorization for 1 hour, filter, and cool the filtrate to 0°C for crystallization. Filter and dry the filter cake under reduced pressure at 60°C to obtain 27g of refined rebamipide sodium salt...

Embodiment 3

[0064] 1) Preparation of the crude product of rebamipide potassium salt

[0065] Put 300ml of isopropanol, 37g (0.10mol) of crude rebamipide, 13g of potassium carbonate and 60ml of water into a 1000ml four-necked bottle in turn, stir, and raise the temperature to 75~80°C to dissolve the solid. Add 2 g of activated carbon, decolorize at this temperature for 1 hour, filter, and cool the filtrate to 0 °C to crystallize 8. Filter, and dry the filter cake under reduced pressure at 60° C. to obtain 28 g of crude rebamipide potassium salt;

[0066] 2) Refined rebamipide potassium salt

[0067] Put 350ml of isopropanol and 28g of crude rebamipide potassium salt into a 500ml four-neck bottle, and raise the temperature to 75~80°C to dissolve the solid. Add 2 g of activated carbon for decolorization for 1 hour, filter, cool the filtrate to 0°C, crystallize, filter, and dry the filter cake under reduced pressure at 60°C to obtain 26 g of refined rebamipide potassium salt;

[0068] 3) H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com