Hydrothermal synthesis method for IVB-group metal oxide

An IVB group, oxide technology, applied in the direction of titanium oxide/hydroxide, zirconia, etc., can solve the problems of low yield, air pollution, increased cost, etc., to achieve obvious effect, excellent performance, and reduce the introduction of impurities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A specific but non-limiting embodiment of the present invention is to use the hydrothermal synthesis method of the present invention to produce zirconia powder. The hydrothermal synthesis method of described zirconia comprises:

[0026] (1) adding the zirconium salt solution to the alkaline precipitating agent to obtain zirconium hydroxide precipitation;

[0027] (2) washing the precipitate to remove other impurities;

[0028] (3) After adding water to the zirconium hydroxide precipitate to prepare a suspension, carry out a hydrothermal reaction to obtain a zirconium oxide suspension;

[0029] (4) Post-processing the zirconia suspension to obtain zirconia powder.

[0030] Specifically, in the above-mentioned step (1), the concentration of the zirconium salt solution is generally 0.02-0.2 mol / L (based on zirconium dioxide), preferably 0.2 mol / L. As the zirconium salt, zirconium oxychloride, zirconium nitrate or zirconium chloride can be used, and zirconium oxychloride...

Embodiment 1

[0040] Preparation of zirconia powder

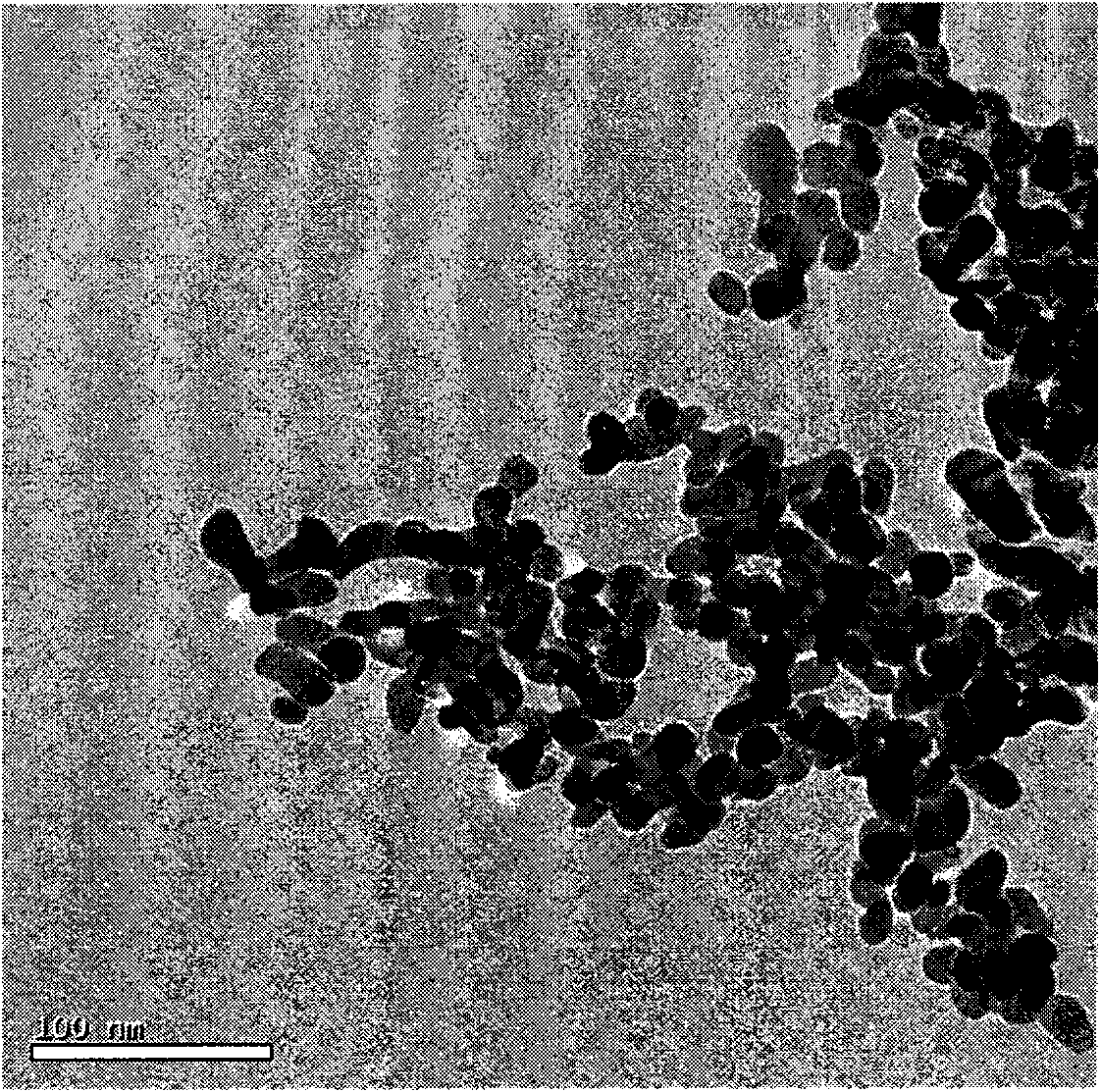

[0041] Weigh 75.0kg of industrial-grade zirconium oxychloride (zirconia content is 36%), add it to 1 cubic meter of ultrapure water, stir into a transparent solution to obtain a zirconium oxychloride solution, and slowly add the solution to 2.5m 2 In the urea solution with pH = 9-10, white flocculent precipitate was obtained, and the reaction ended when pH = 8. Wash the precipitate with Class II electronic industrial water until there is no Cl in the precipitate - exist. Centrifuge the precipitate, then transfer the precipitate to a hydrothermal reactor, add 0.5m3 Heat ultrapure water to 150°C and keep it for 16 hours. When the temperature is lowered to below 100°C, wash the precipitate with II-grade electronic industrial water until no impurity ions exist in the precipitate. After spraying granulation and jet crushing, the zirconia powder can be obtained. figure 1 TEM photo of the obtained powder.

[0042] The zirconia powder is bidi...

Embodiment 2

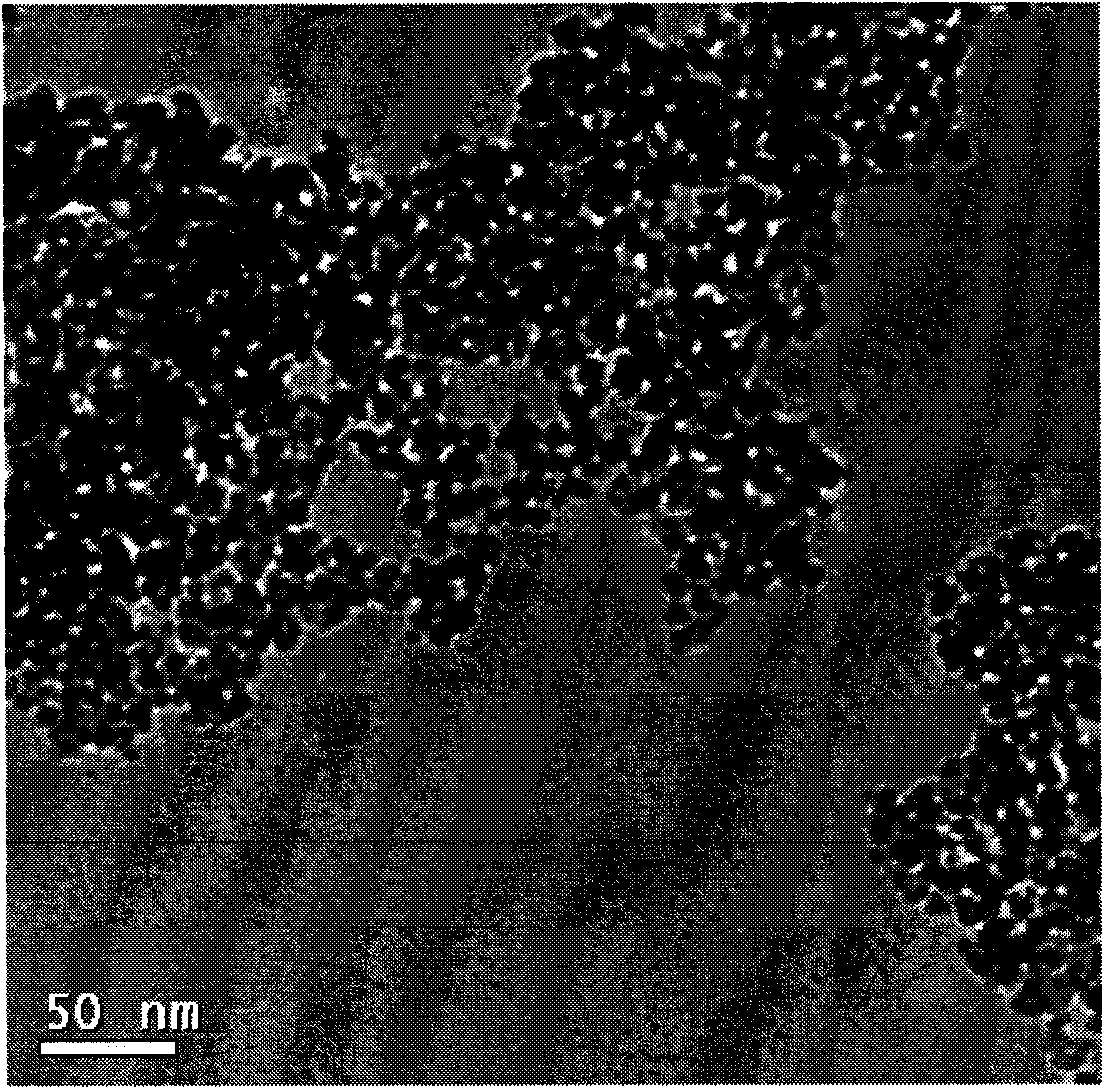

[0044] Preparation of zirconia powder (with mineralizer added)

[0045] Weigh 75.0kg of industrial-grade zirconium oxychloride (the content of zirconia is 36%), add it to 1 cubic meter of ultrapure water, and stir it into a transparent solution to obtain a zirconium oxychloride solution, which is slowly added to 2.5m 2 In the urea solution with pH = 9-10, white flocculent precipitate was obtained, and the reaction ended when pH = 8. Wash the precipitate with Class II electronic industrial water until there is no Cl in the precipitate - exist. Centrifuge the precipitate, then transfer the precipitate to a hydrothermal reactor, add 0.5m 3 Add 500g of magnesium hydroxide to ultrapure water, heat it to 150°C and keep it for 16 hours. When the temperature drops below 100°C, wash the precipitate with II-grade electronic industrial water until there are no impurity ions in the precipitate. Spray granulation and jet crushing. Zirconia powder was obtained. figure 2 TEM photo of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com