Novel standard metal measuring vessel with double-layer structure and internally-clamped heat insulation layer for testing oiling machine

A standard metal gauge, metal gauge technology, applied in instruments, measuring devices, test/calibration devices, etc., can solve the problems of poor comprehensive function and unreasonable design, achieve simple structure, stable measurement performance, and improve oil filling position. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

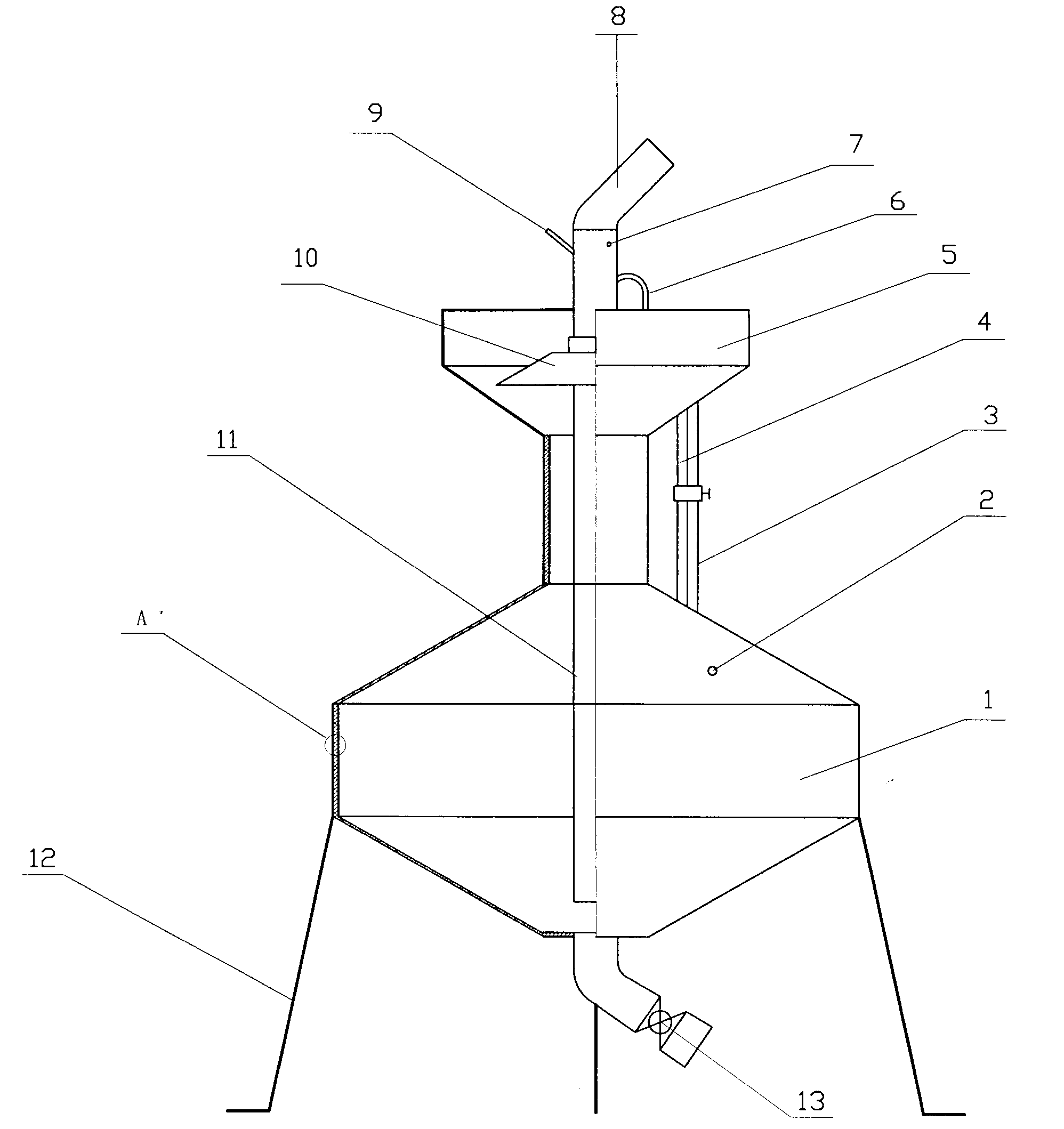

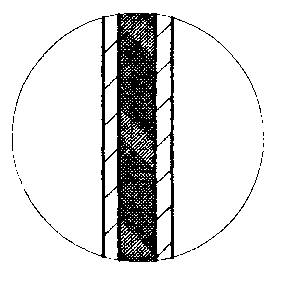

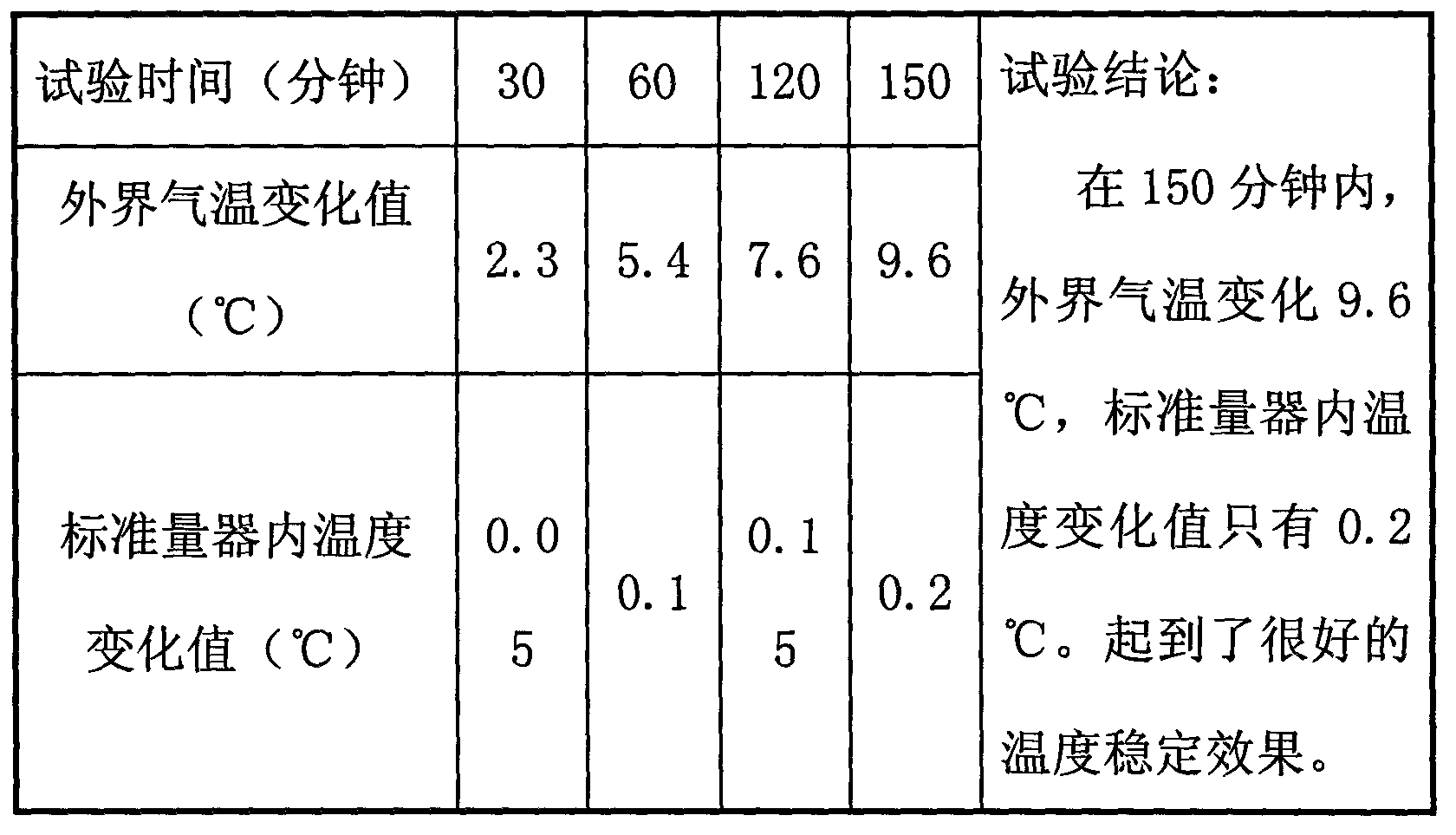

[0033] as attached figure 1 In the illustrated embodiment, the present invention is provided with: a standard metal measuring instrument main body, a liquid level tube 1, a refueling gun bracket 8, a catheter tube 4, an overflow cover 11, a gun mouth temperature measuring hole sleeve 7, and a metal measuring instrument main body Oil temperature measurement hole sleeve 10, liquid discharge valve 8, bracket 9, liquid splash-proof cone cover plate 5, pressure relief diverter elbow 12, the main body of the standard metal gauge is a metal gauge body with a double-layer metal plate structure and an insulating layer inside 3. The top of the liquid level tube 1 is connected with two vernier calipers 2 installed at 90° to each other (for example, one vernier caliper faces south and the other faces east), and the refueling gun bracket 6 is a movable refueling gun bracket 6. The catheter tube 4 connected to the gun bracket 6 is equipped with a pressure relief shunt elbow 12 and is shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com