Micro-channel radiator structure and preparation method thereof

A heat sink and micro-channel technology, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of low heat dissipation efficiency, simple structure of silicon-based micro-channels, and inability to meet chip heat dissipation, etc., to achieve Uniform heat dissipation capacity, strong heat dissipation effect, and uniform heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

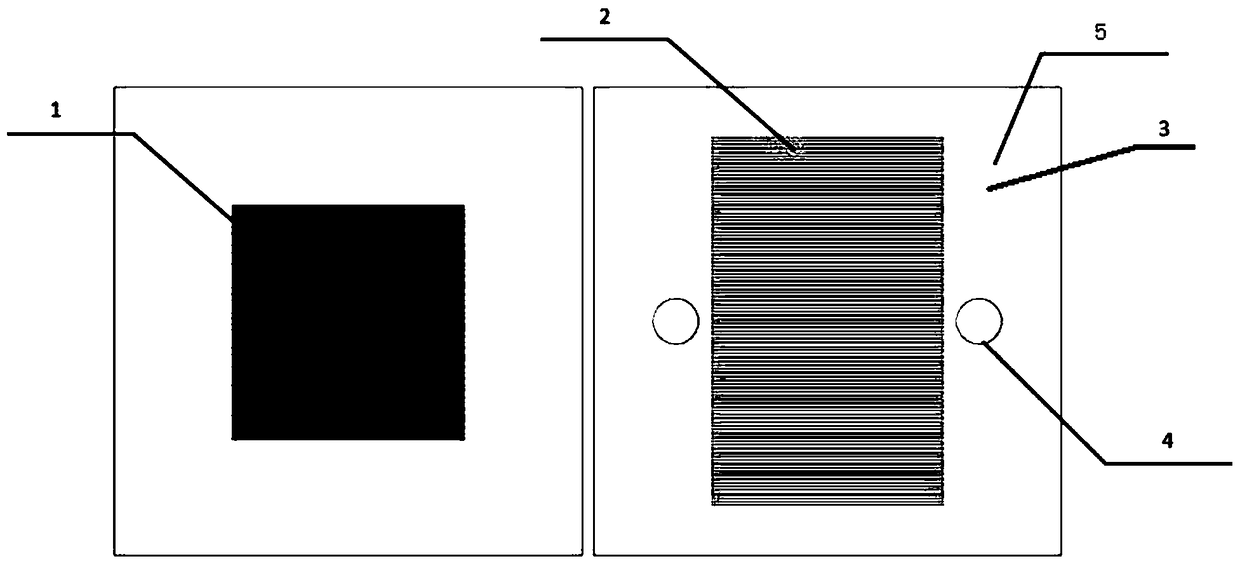

[0034] As an embodiment of the present invention, the distribution channels 3 are evenly arranged to make the cooling liquid spread evenly between the embedded channel 2 and the liquid inlet / outlet port 4 .

[0035] As an embodiment of the present invention, the width of the open channel 1 is the same as that of the embedded channel 2 .

[0036] The embedded channel 2 has a width of 5µm-100µm and a depth of 30µm-500µm. Preferably, the embedded channel 2 has a width of 10µm to 50µm and a depth of 100µm to 300µm. As an embodiment of the present invention, the width is 50 µm and the depth is 300 µm.

[0037] As an embodiment of the present invention, the depth of the branch flow channel 3 is the same as that of the embedded flow channel 2 .

[0038] As an embodiment of the present invention, the branch flow channel 3 is arranged inside the A silicon wafer.

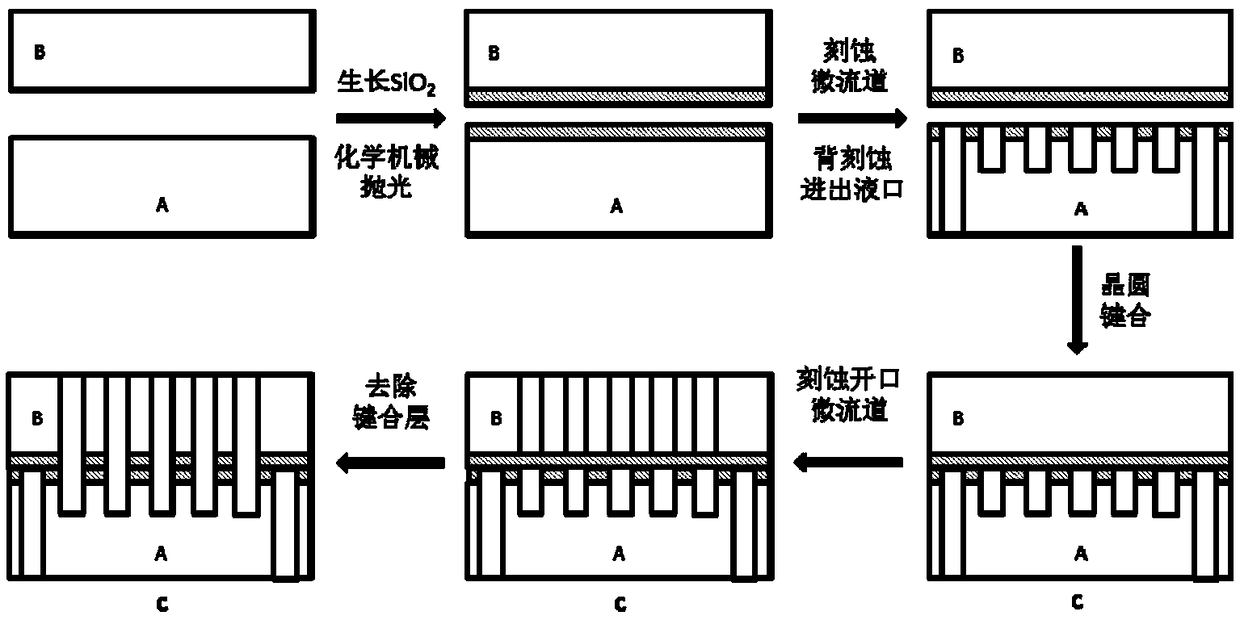

[0039] Such as image 3 As shown, a method for preparing a microchannel heat sink structure is used to prepare the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com