Liquid flow frame for liquid flow battery

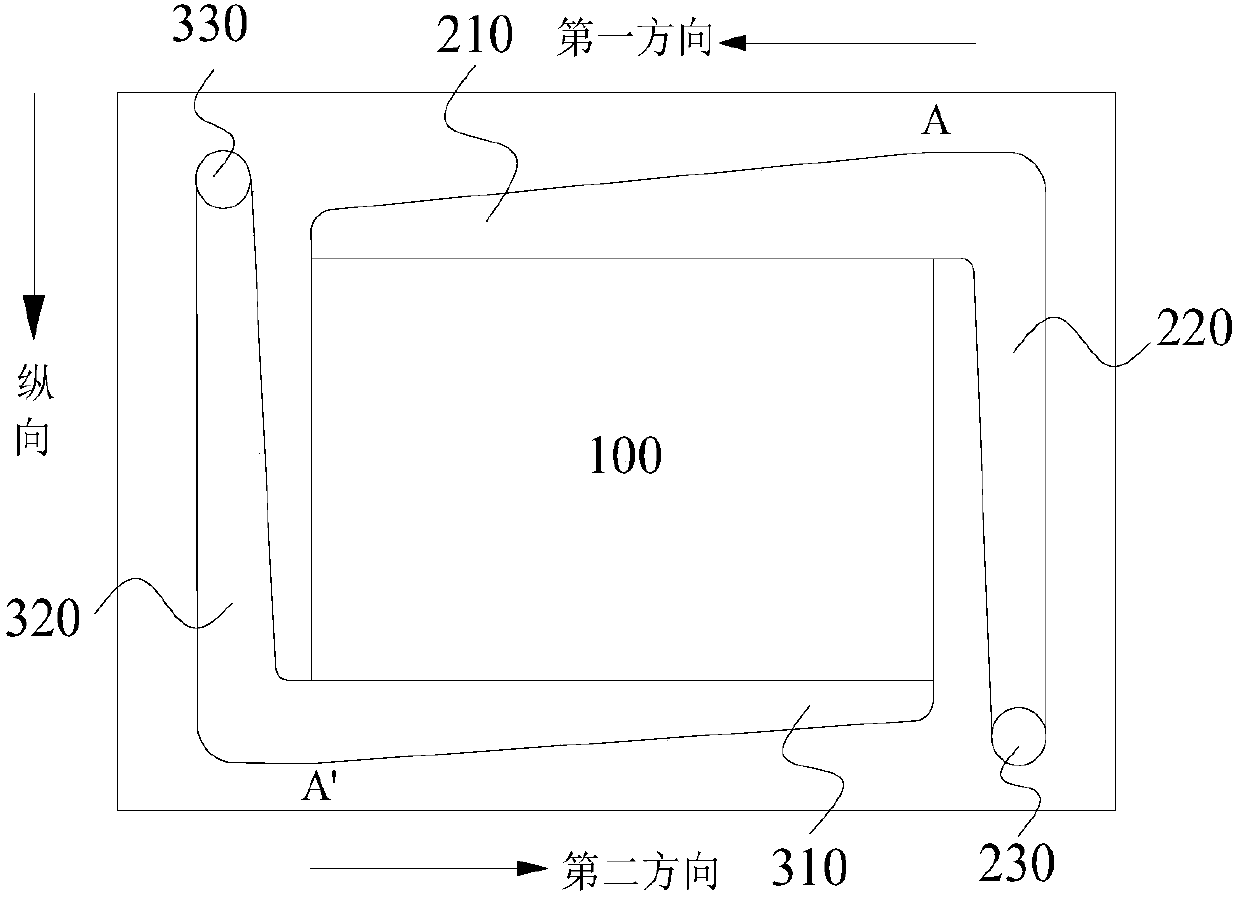

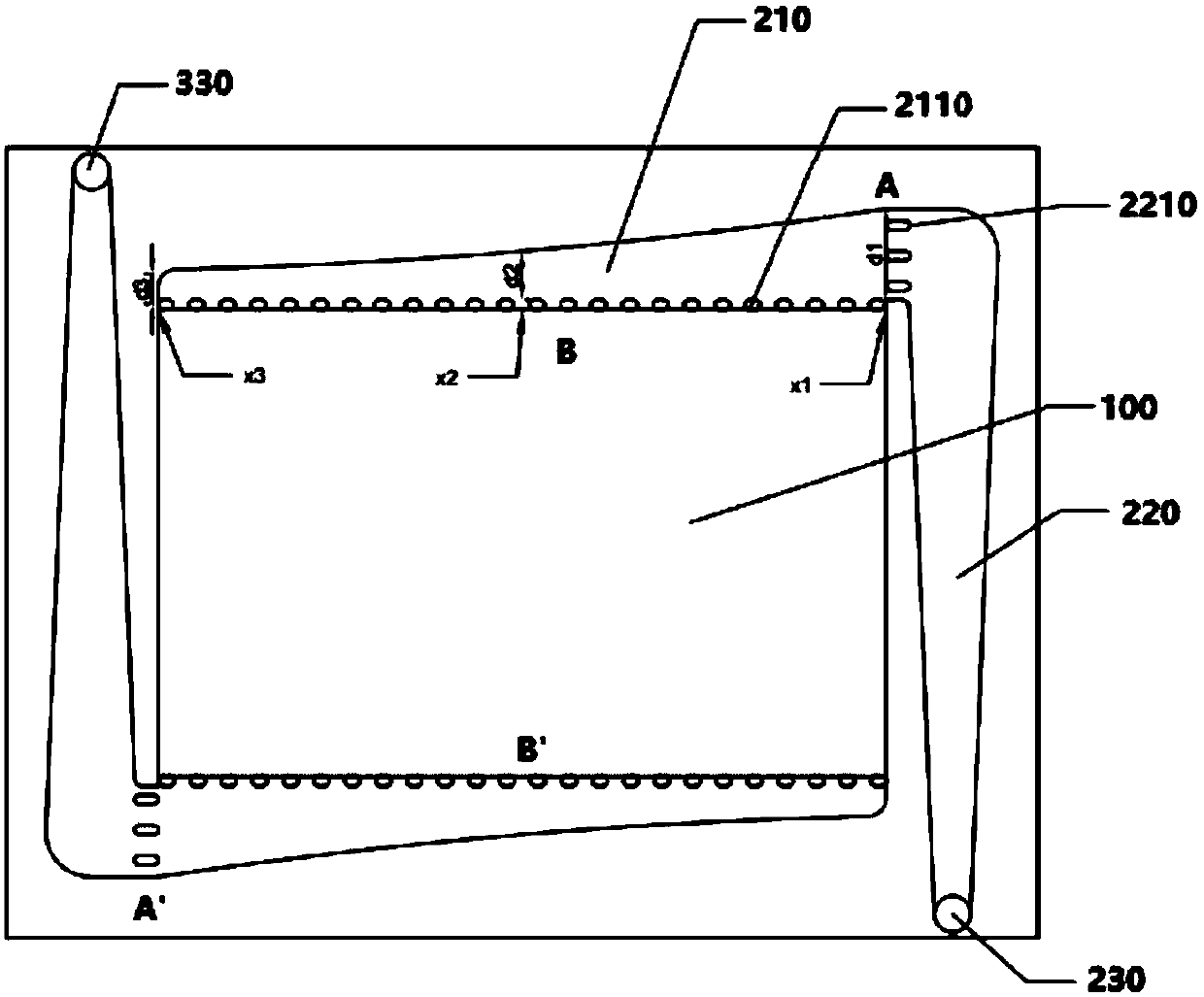

A flow battery and flow frame technology, applied in the field of flow frame, can solve the problems of unsatisfactory battery efficiency of all-vanadium flow battery, short battery life, and the structure of the flow frame of all-vanadium flow battery needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

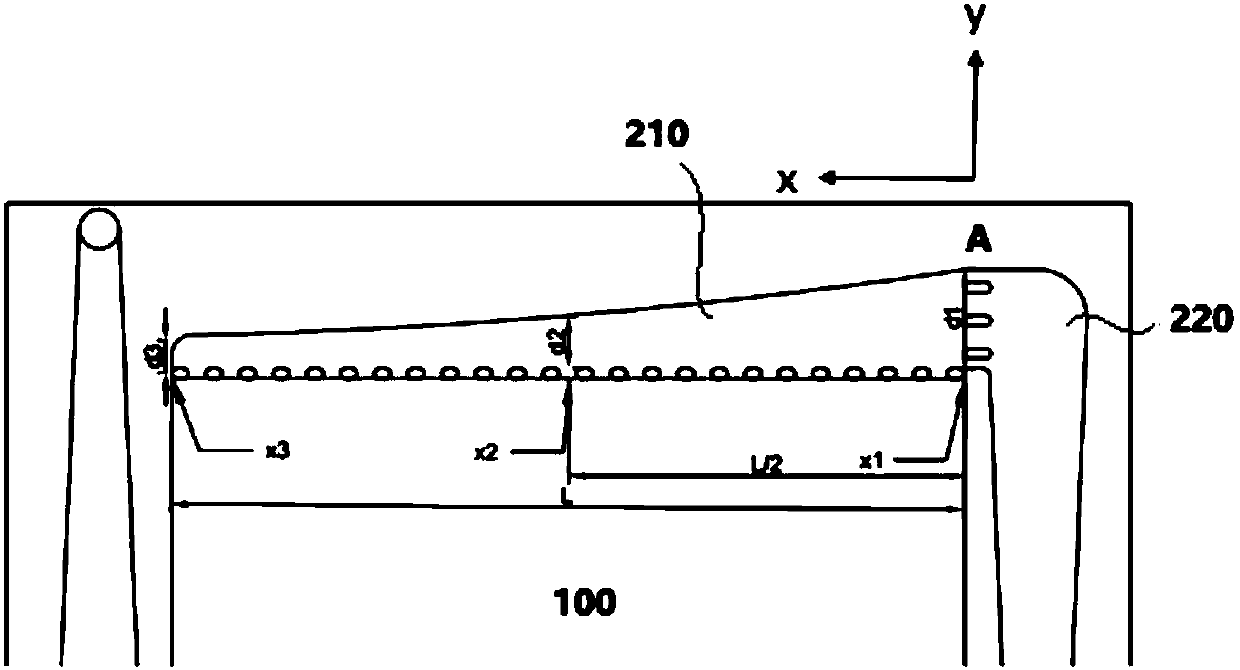

[0059] In this embodiment, a fluid dynamics simulation is performed on the liquid inlet channel of the liquid flow frame. Among them, the specific conditions of the simulation are that the inlet flow velocity is set to be equal to 0.4m / s, and the outlet is set to be equal pressure outlet. In this example, the length of the tapered flow channel is 120mm, and the parameters in formula 1 are a=1 / 1800, b =1 / 60, c=5.

[0060] The fluid simulation results of this embodiment are as follows Figure 5 As shown, the simulation results indicate the distribution of electrolyte velocity (Velocity) inside the flow channel and out of the shunt flow channel with a tapered longitudinal cross-sectional area. Depend on Figure 5 It can be seen that the shunt channel with tapered longitudinal cross-sectional area can realize the uniform distribution of the flow rate and velocity of the electrolysis flowing into the porous electrode, which can meet the uniform distribution effect of the electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com