Air conditioner gas bypass noise reduction method and structure

A technology for air conditioning and noise reduction, applied in the direction of noise suppression, etc., can solve the problems of severe vibration of bypass pipeline and suction pipe, obvious low-frequency noise, and large air flow noise, and achieve the goal of reducing air bypass noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is further described.

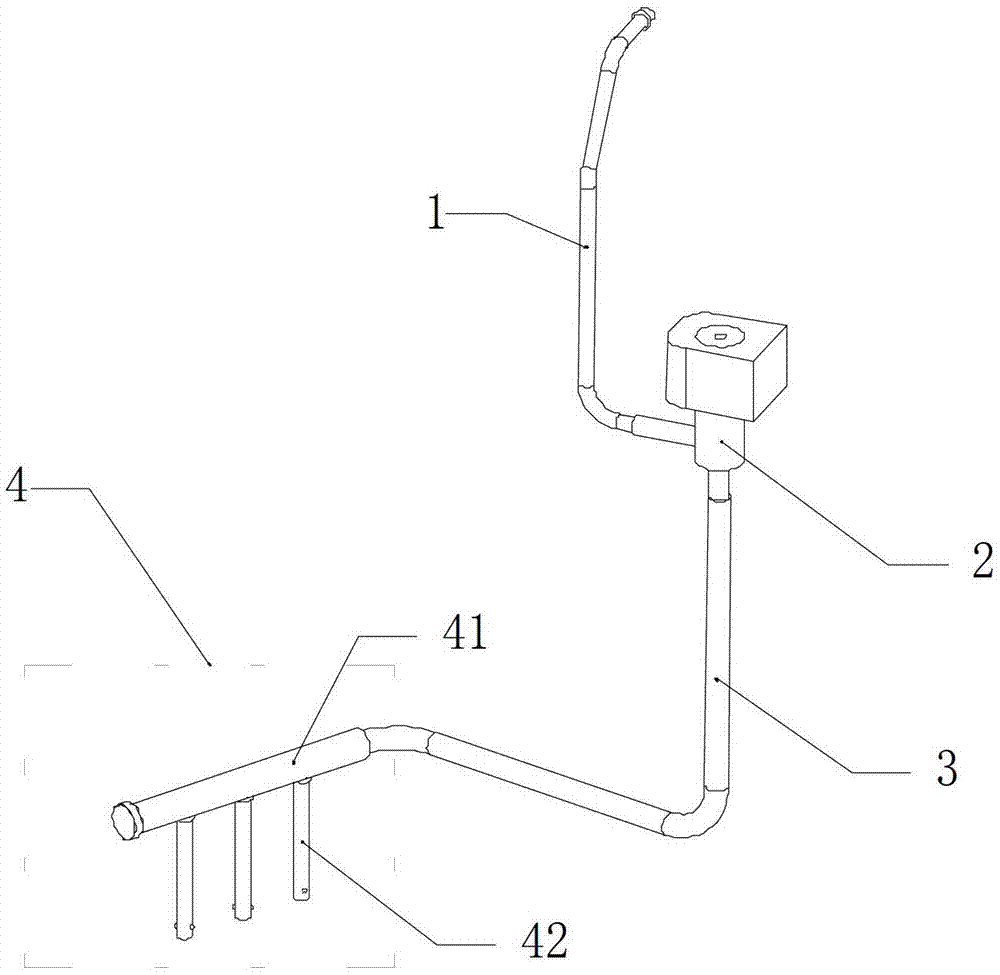

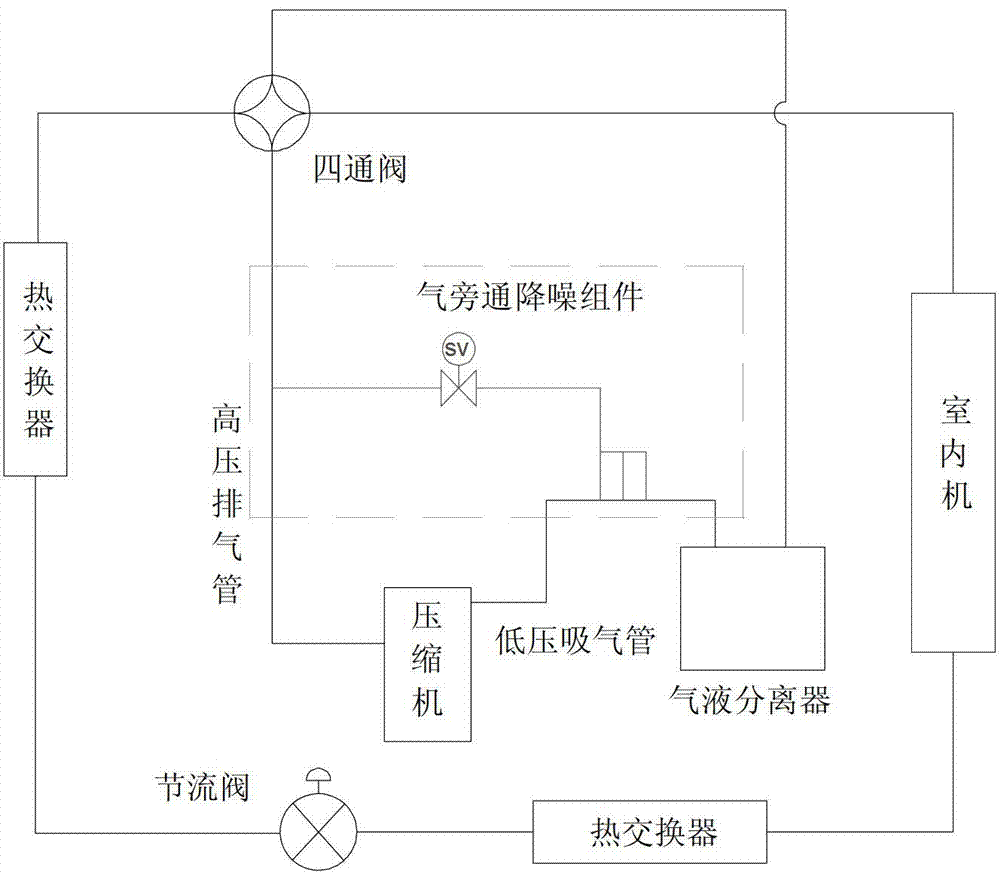

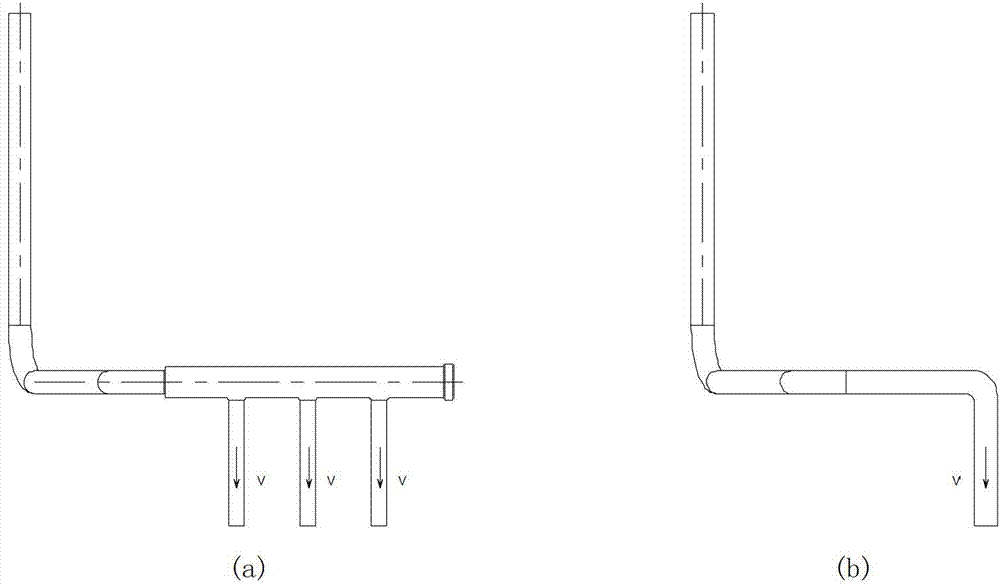

[0021] A kind of air-conditioning air bypass noise reduction method, comprises the following steps: A, an air bypass noise reduction structure is set between the high-pressure exhaust pipe and the low-pressure suction pipe of the air conditioner, the air-bypass noise reduction structure is located between the low-pressure suction pipe One end is a split flow noise reduction component; B. Use the high and low pressure bypass refrigerant flow split calculation to determine the number and diameter of the split pipes of the split flow noise reduction component and the air flow velocity in each tube. The suction side bypass connecting pipe of the present invention adopts multi-way shunting to enter the suction pipe, and the number of multi-way shunting pipes and the selection of pipe diameters are calculated by the method of high and low pressure bypass refrigerant shunting.

[0022] The high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com