Method and apparatus for substrate temperature control

a temperature control and substrate technology, applied in the direction of instruments, liquid/fluent solid measurement, structural/machine measurement, etc., can solve the problems of reducing the accuracy of the correlation between the flow indicated and the actual flow to both, the deviation of the process performance of the substrate to the substrate, and the effect of affecting the accuracy of the correlation between the flow and the actual flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

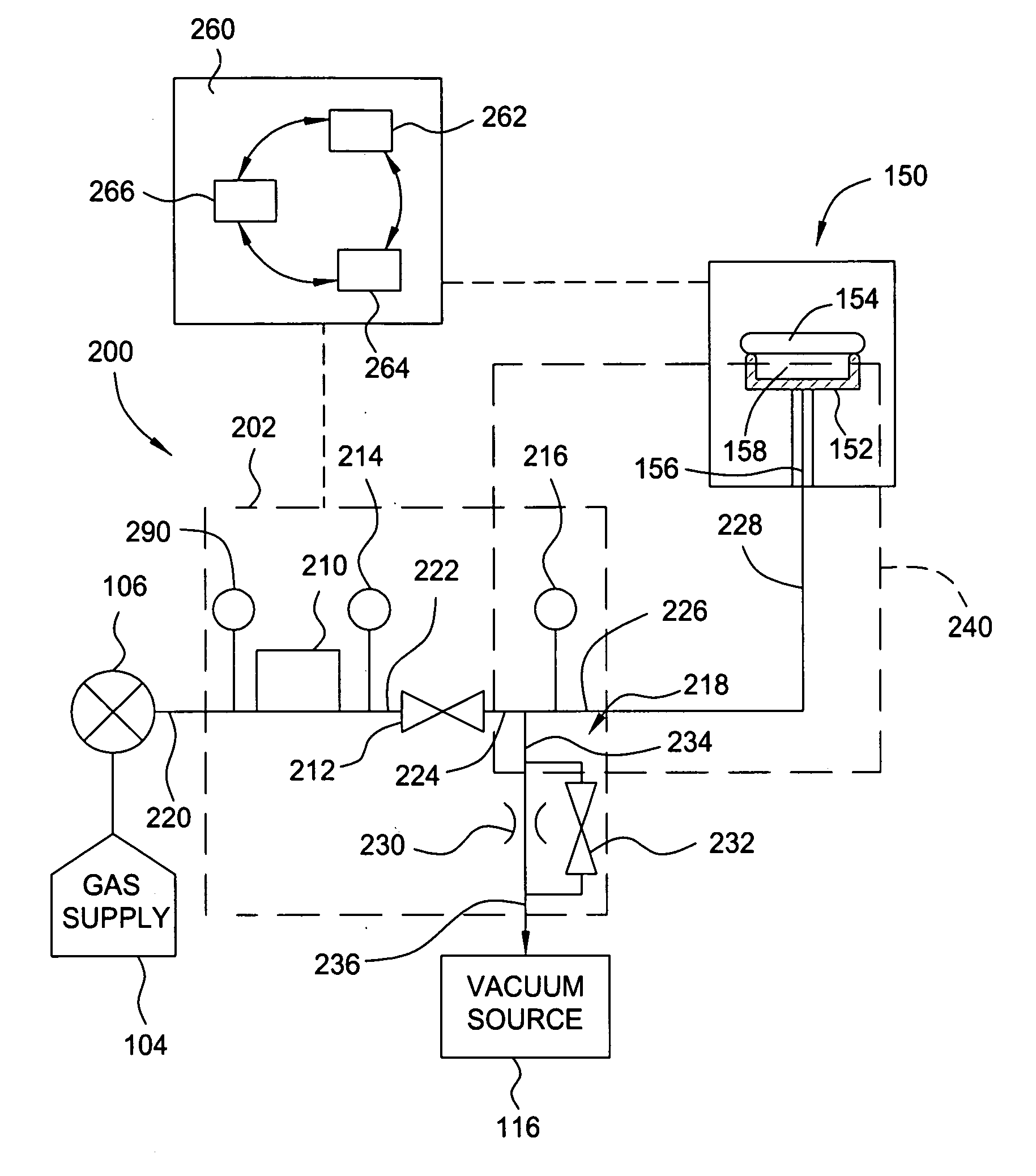

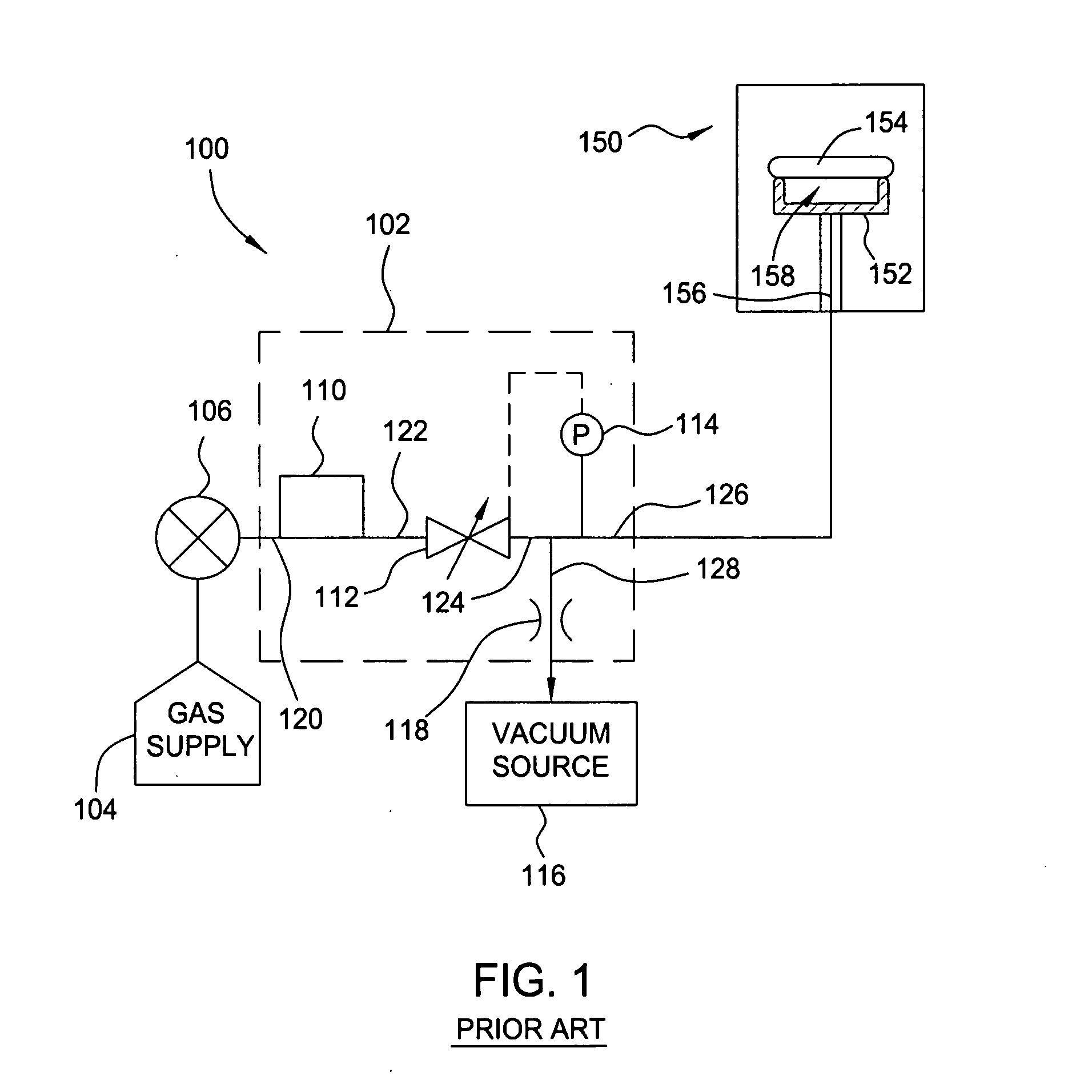

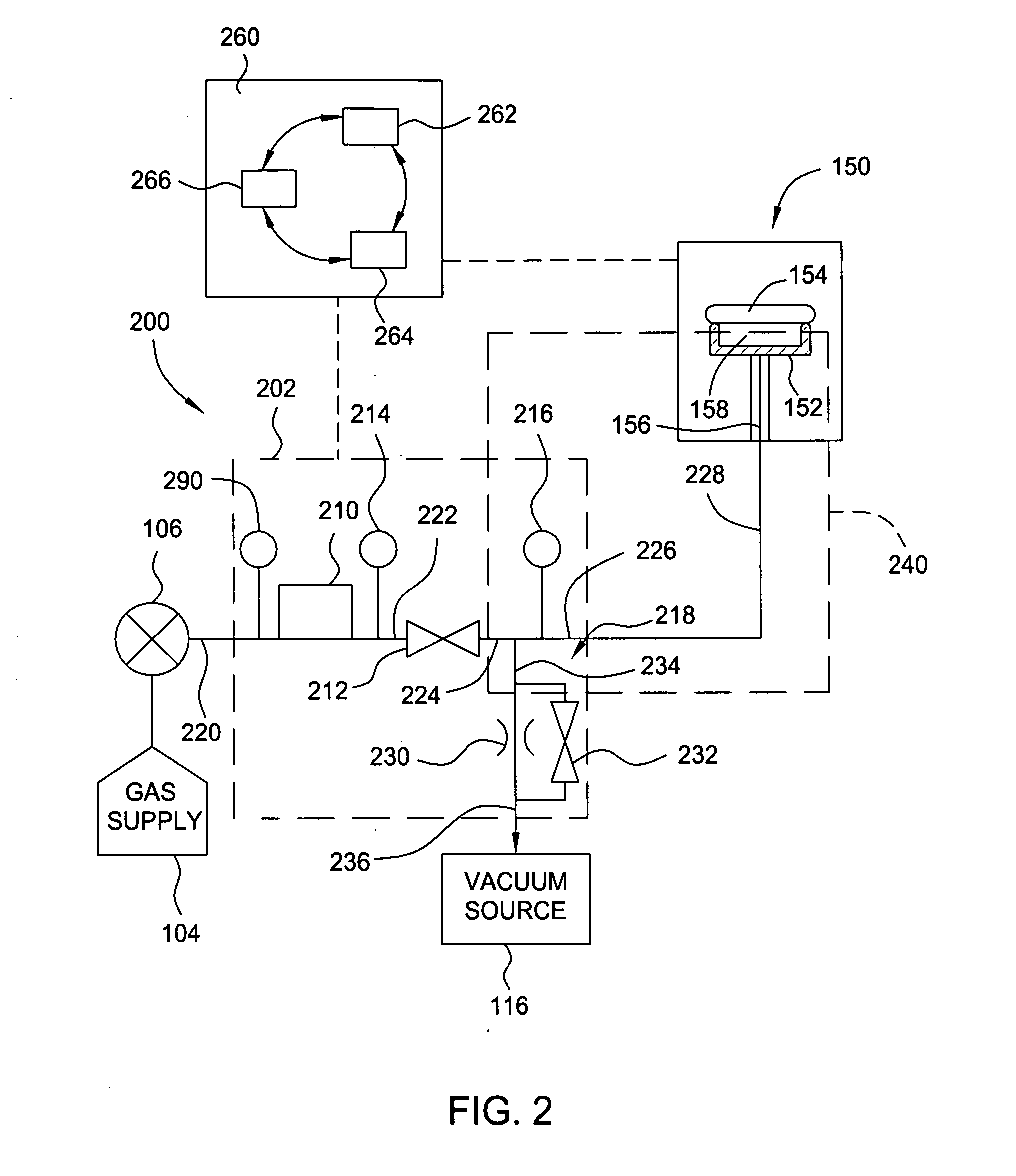

[0024]FIG. 2 depicts a simplified schematic of one embodiment of a gas delivery system 200 of the invention coupled to an exemplary a semiconductor processing chamber 150. As described above, the processing chamber 150 includes a substrate support 152 disposed therein which supports a substrate 154 during processing. The processing chamber 150 may be configured to perform chemical vapor deposition (CVD), physical vapor deposition (PVD), etch chamber or other vacuum processing technique. Process gas delivery systems, pumping systems and the like for controlling processes performed within the processing chamber are well-known and have been omitted for the sake of brevity.

[0025] The substrate support 152 generally includes a passage 156 formed therethrough for delivering a heat transfer gas (hereinafter referred to as backside gas) to an area 158 defined between the substrate 154 and substrate support 152. The size of the area 158 has been exaggerated in FIG. 2 for clarity. The backsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com