Stepped recycle method for residual heat of fuel gas

A flue gas waste heat and cascaded recovery technology, applied in the direction of preheating, feed water heater, heat exchanger, etc., can solve the problem of low cost performance of heat recovery, achieve the effect of reducing content, reducing emissions, and improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

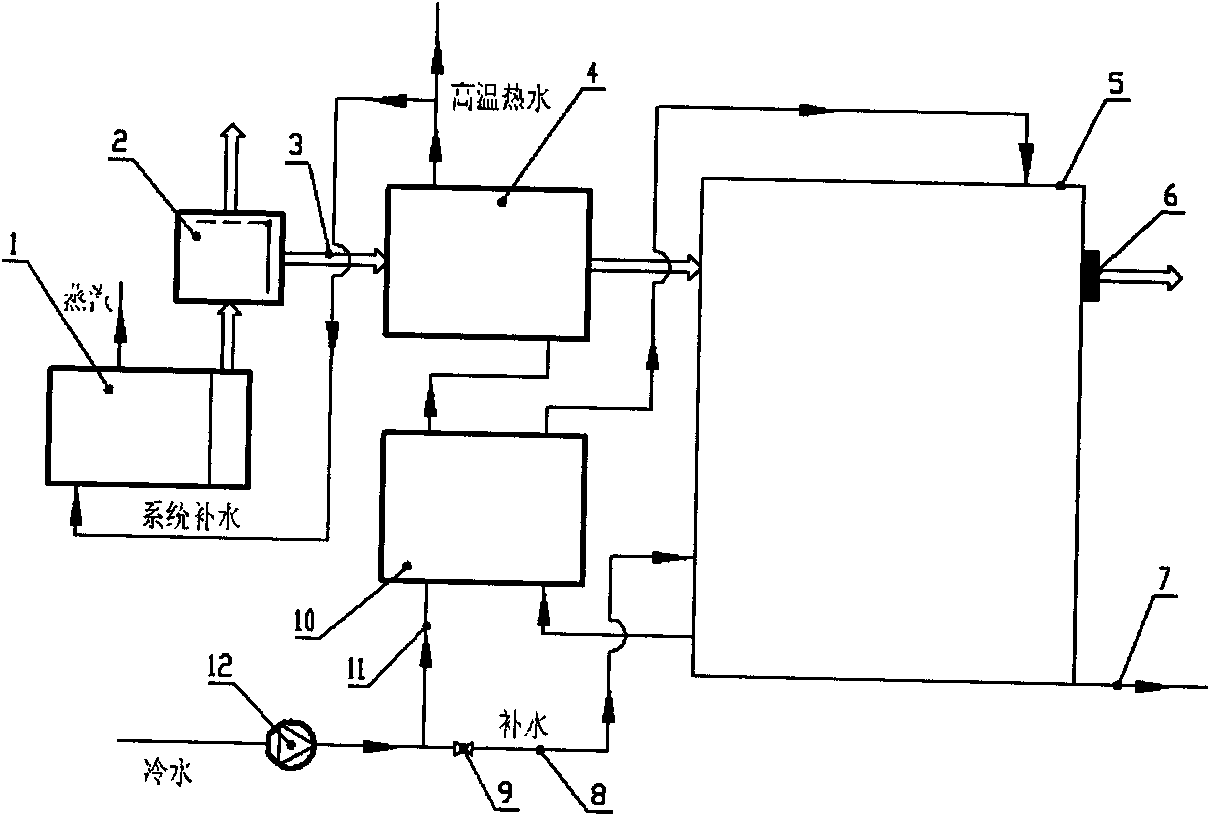

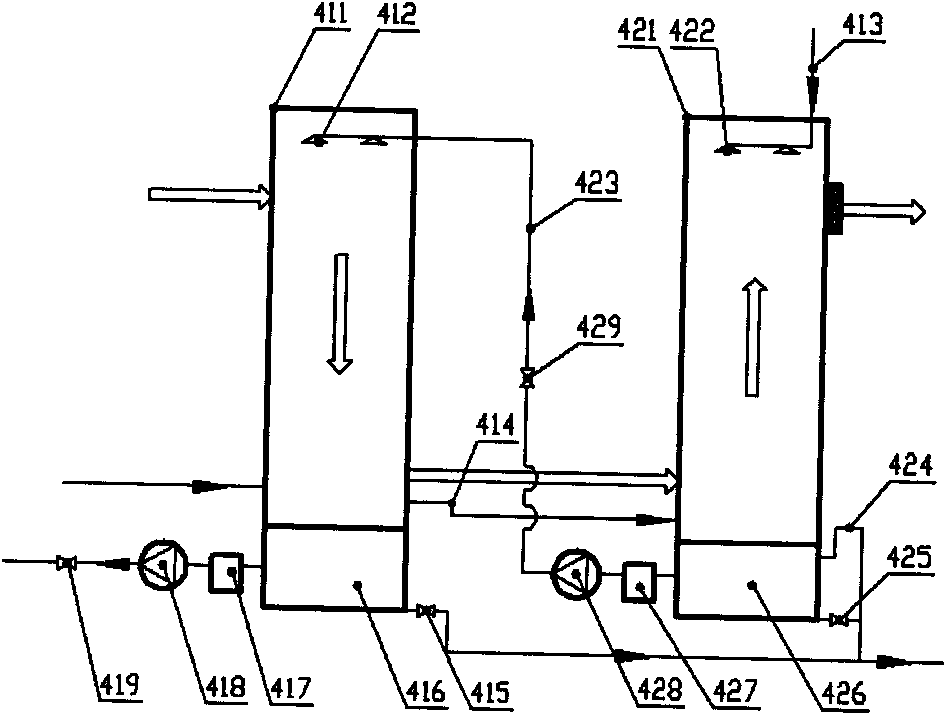

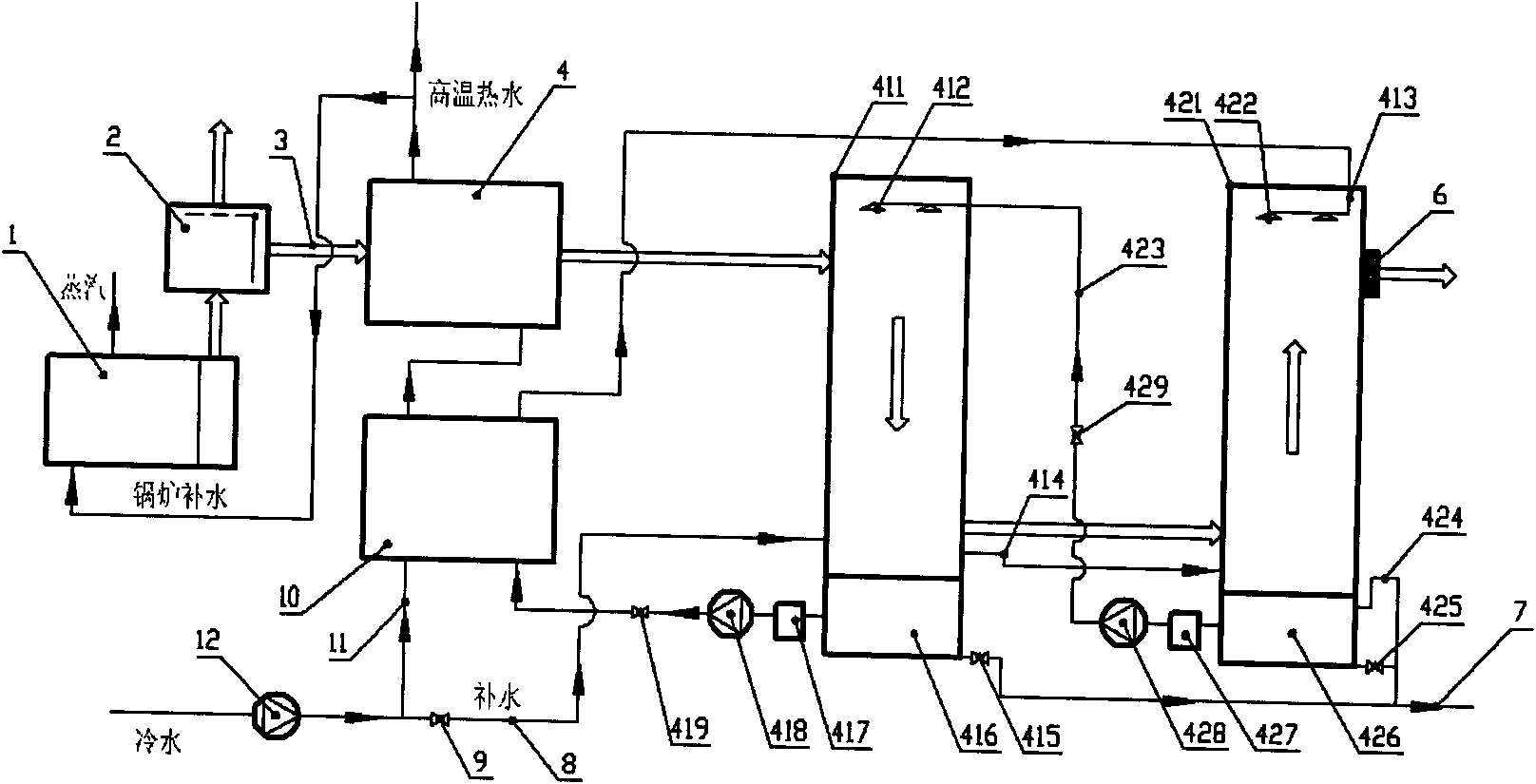

[0025] exist image 3 Among them, the 200°C high-temperature flue gas discharged from the gas-fired steam boiler 1 enters the gas-water heat exchanger 3 through the flue gas switching device 2 along the flue gas pipeline 3, and the high-temperature flue gas and the passing water in the gas-water heat exchanger 3 The heat exchanger 12 absorbs the heat of the spray water for indirect heat exchange, the temperature drops to 100°C, and after releasing part of the sensible heat, it enters the primary spray tower 411; in the primary spray tower 411, the flue gas Up-down movement, the liquid droplets sprayed from the first-stage nozzle 412 on the top of the first-stage spray tower 411 move from top to bottom, the liquid droplets and the flue gas move in the same direction, and perform direct contact heat exchange while reducing the resistance of the flue gas. The flue gas temperature is reduced to 65°C at the outlet of the primary spray tower 411, and most of the sensible heat is rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com