Flue gas desulfurization process for comprehensively utilizing hot waste gas of circulation cooler in sintering process

A desulfurization process and a technology for hot waste gas, applied in the field of waste gas treatment and comprehensive utilization process, can solve the problems of resource and energy waste, adverse impact on the atmospheric environment, etc., and achieve the effect of saving energy, protecting the quality of the atmospheric environment, and facilitating dilution and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

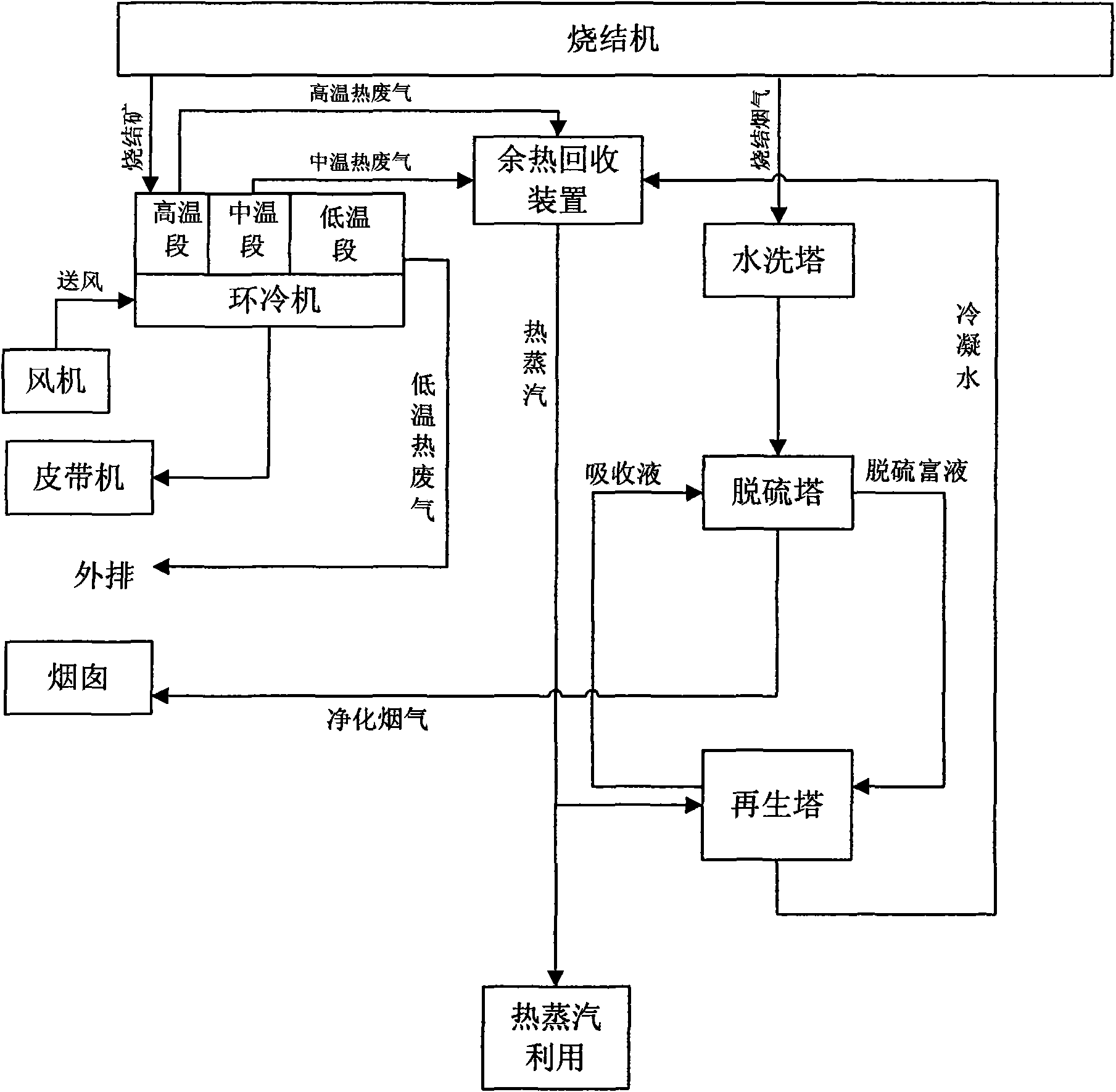

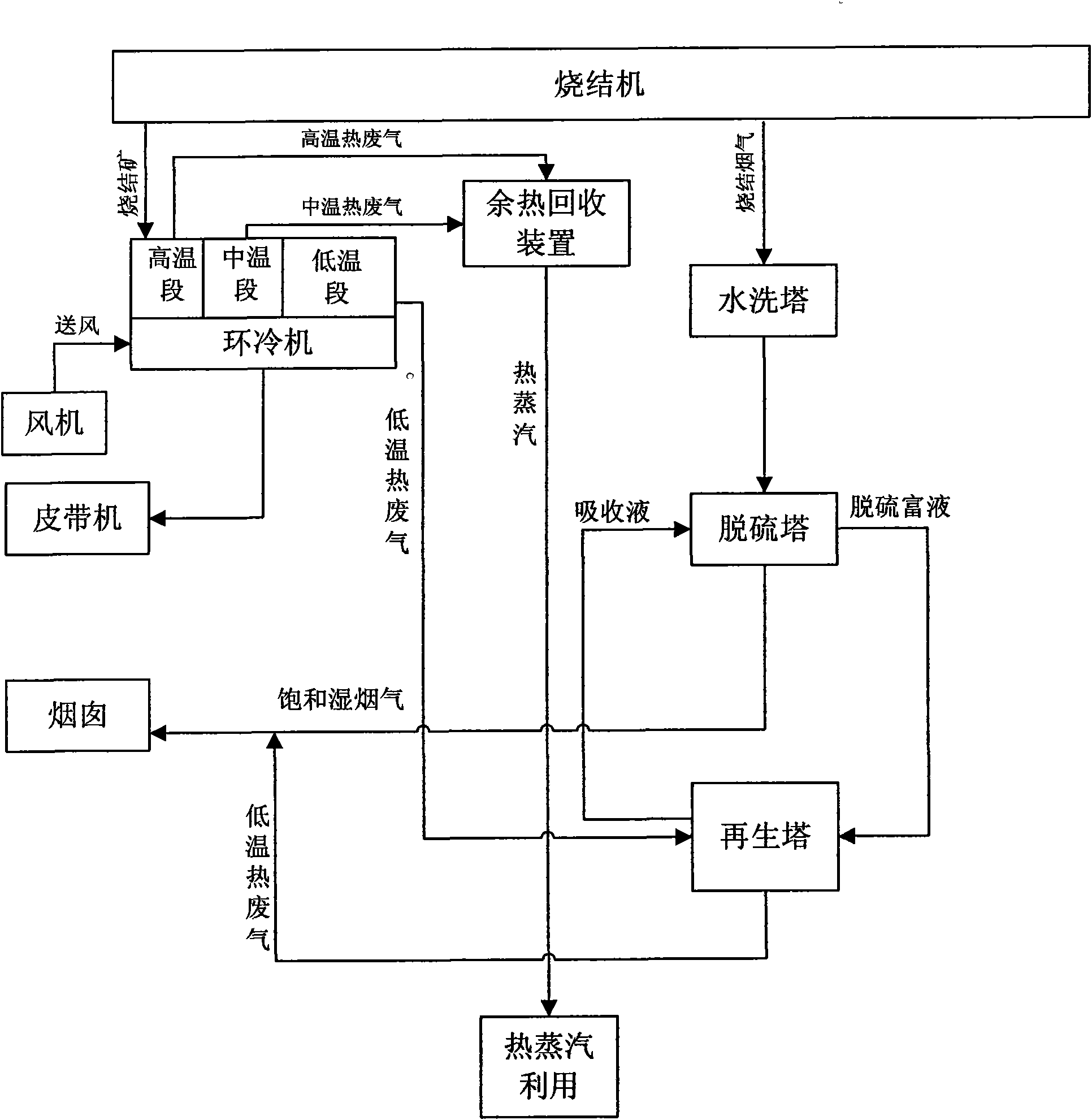

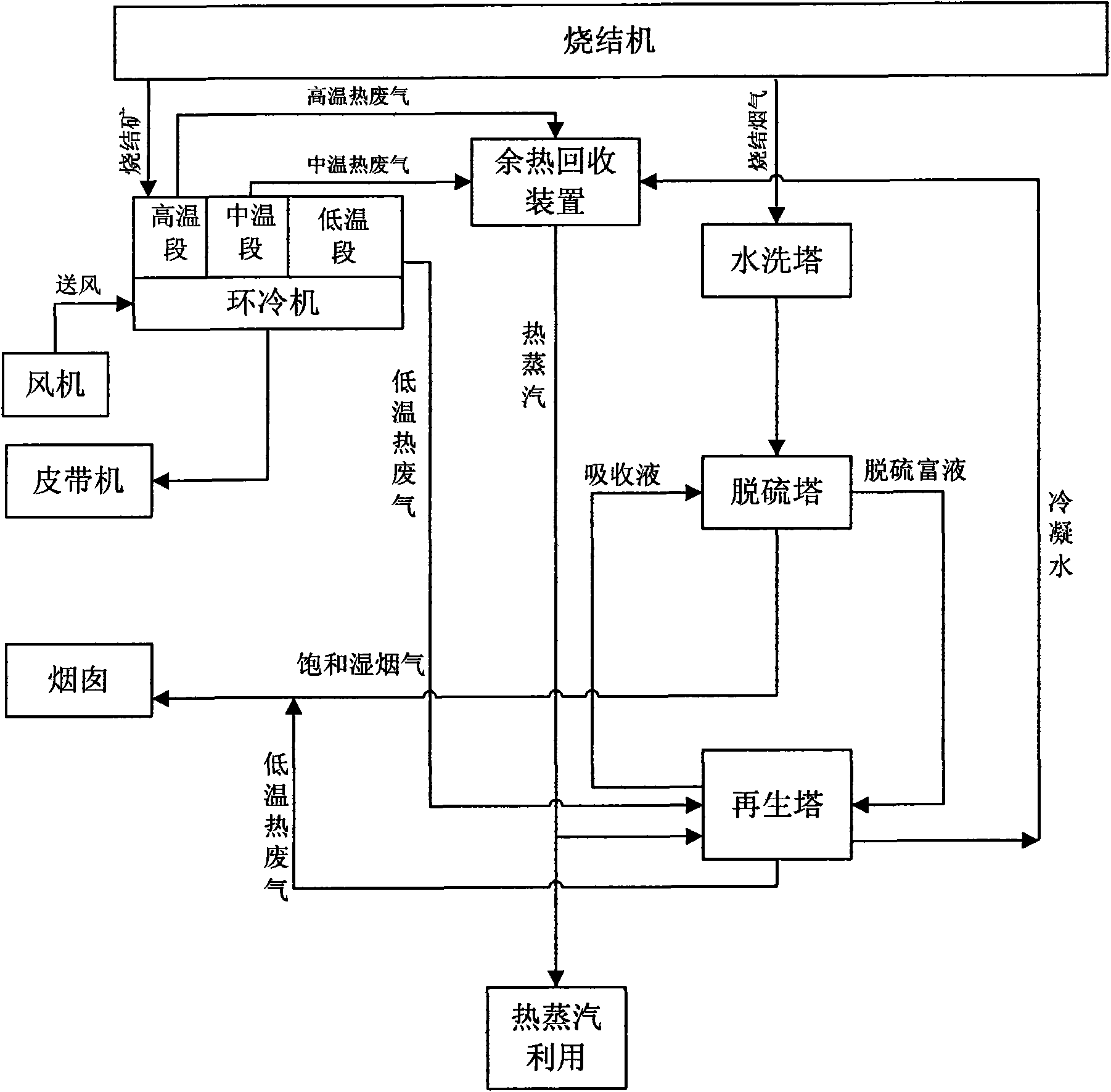

[0021] Such as figure 2 Shown is the flue gas desulfurization process of the present invention, which is used for the flue gas desulfurization of the iron ore sintering process. Sintering machine (effective sintering area is 360m 2 ) The roasted sinter passes through the ring cooler (the cooling air volume is about 2300000Nm 3 / h) After cooling, the grains are sized and then sent to the blast furnace by a belt conveyor. The sintering flue gas discharged from the sintering process of the sintering machine is pressurized by the booster fan and then enters the water washing tower (the water washing tower may not be installed, but a washing section is set in the desulfurization tower, and the sintering flue gas is directly sent to the washing section). After the tower is washed with washing water, cooled and dedusted, the temperature of the sintering flue gas is reduced to 40°C to 60°C.

[0022] The sintered flue gas washed with water is sent to the desulfurization tower again,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com