Device for smoke condensation haze-eliminating and white-removing after wet desulphurization and technical method

A flue gas condensation, wet desulfurization technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low exhaust gas temperature, equipment corrosion, uneconomical and other problems, and achieve the reduction of concentration and total emission, The effect of reducing system water consumption and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

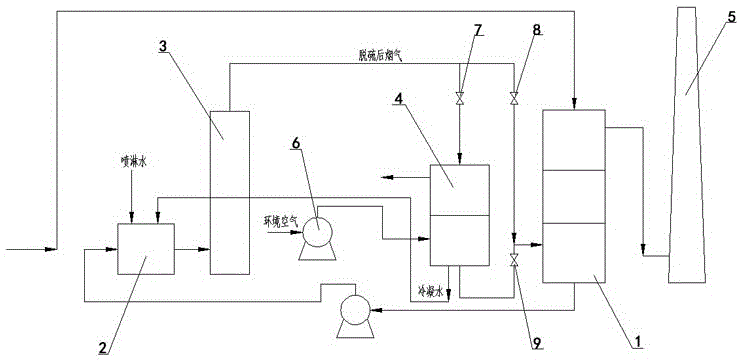

[0024] As shown in the figure: a flue gas condensation and haze removal equipment after wet desulfurization, including a flue gas dehumidifier 1, a water spray tower 2, a desulfurization tower 3 and a flue gas deep cooler 4, the flue gas dehumidifier 1 has a first medium channel and a second medium channel for mutual heat exchange, and the flue gas cryocooler 4 has a flue gas channel and an air channel for mutual heat exchange, and both the flue gas dehumidifier 1 and the flue gas cryocooler 4 are of glass plate type Heat Exchanger. The air channel inlet of the flue gas cryocooler 4 is connected with a blower 6 for introducing ambient air into the flue gas cryocooler 4 for heat exchange. The inlet of the first medium channel of the flue gas dehumidifier 1 is connected to the pretreated flue gas, the outlet of the first medium channel is connected to the water spray tower 2, and the gas outlet of the water spray tower 2 is connected to the desulfurization tower through a pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com