Patents

Literature

51results about How to "Realize heat recovery and utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

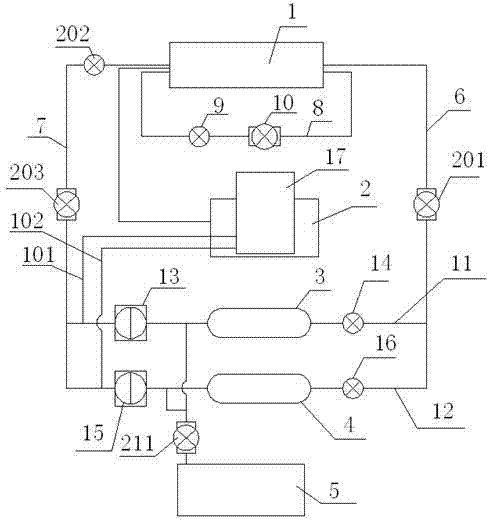

Three-tube multi-split air-conditioning system oil return or defrosting control method and system thereof

InactiveCN104792076APrevent freezingAvoid cloggingMechanical apparatusCorrosion preventionUnit systemEngineering

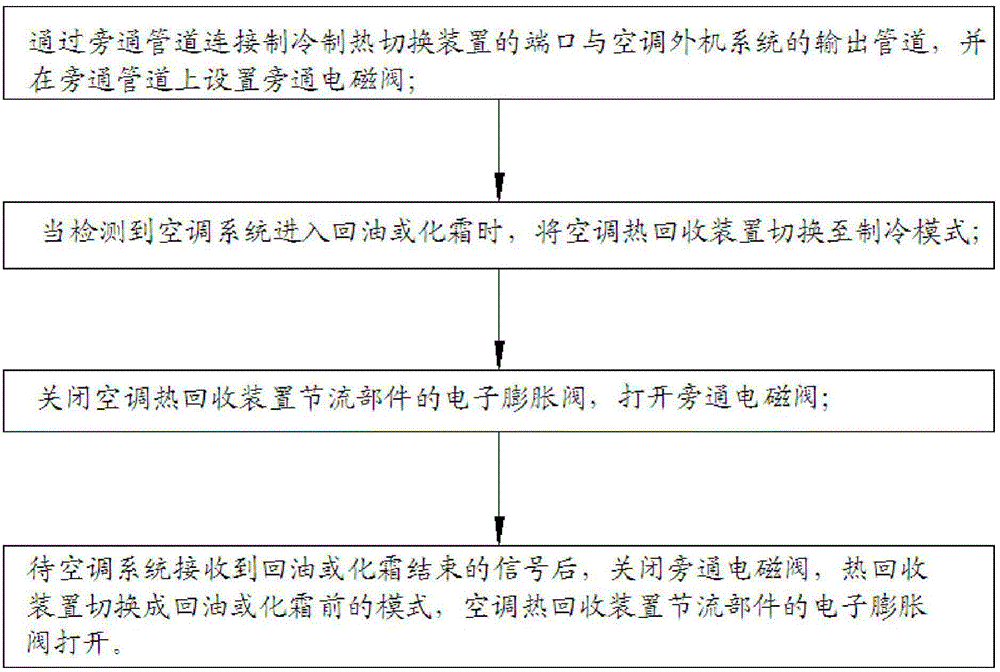

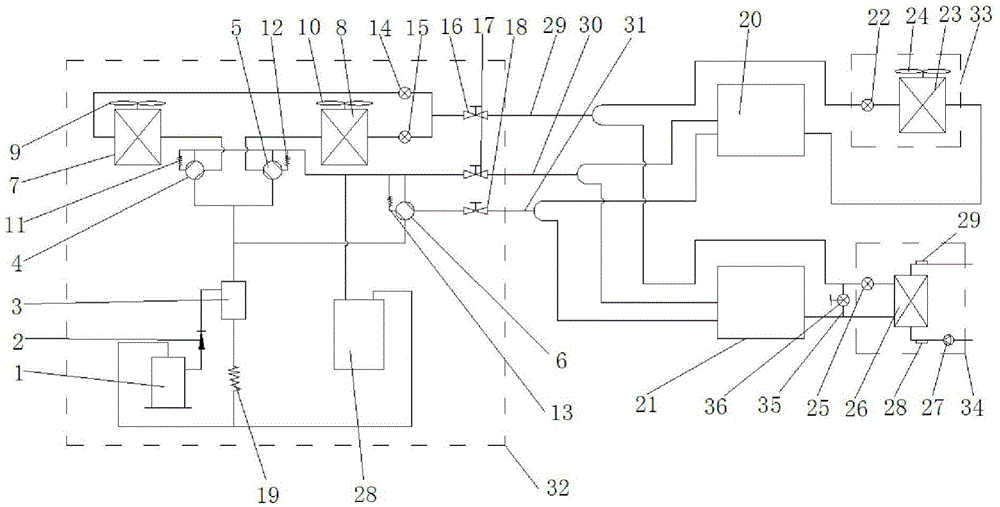

The invention relates to a three-tube multi-split air-conditioning system oil return or defrosting control method and a system thereof. The method includes the following steps that step1, a port of refrigerating / heating switching device and an output pipe of an air-conditioning external unit system through a bypass pipe, the bypass pipe is provided with a bypass electromagnetic valve, and whether an air-conditioning system enters the oil return or defrosting state or not is detected in real time; step 2, when the air-conditioning system enters the oil return or defrosting state, an air-conditioning heat recycling device is switched into the refrigerating mode; step 3, an electromagnetic expansion valve of a throttling part of the air-conditioning heat recycling device is turned off, and the bypass electromagnetic valve is turned on; step 4, after the air-conditioning system receives the ending signal of oil return or defrosting, the bypass electromagnetic valve is turned off, and the electromagnetic expansion valve of the throttling part of the air-conditioning recycling device is turned on. According to the three-tube multi-split air-conditioning system oil return or defrosting control method and the system thereof, coolants do not pass through a hydraulic module system, and the situations that the hydraulic module system is frozen due to the coolants, and thus pipes are blocked are avoided on the premise of meeting the oil return and defrosting requirements.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

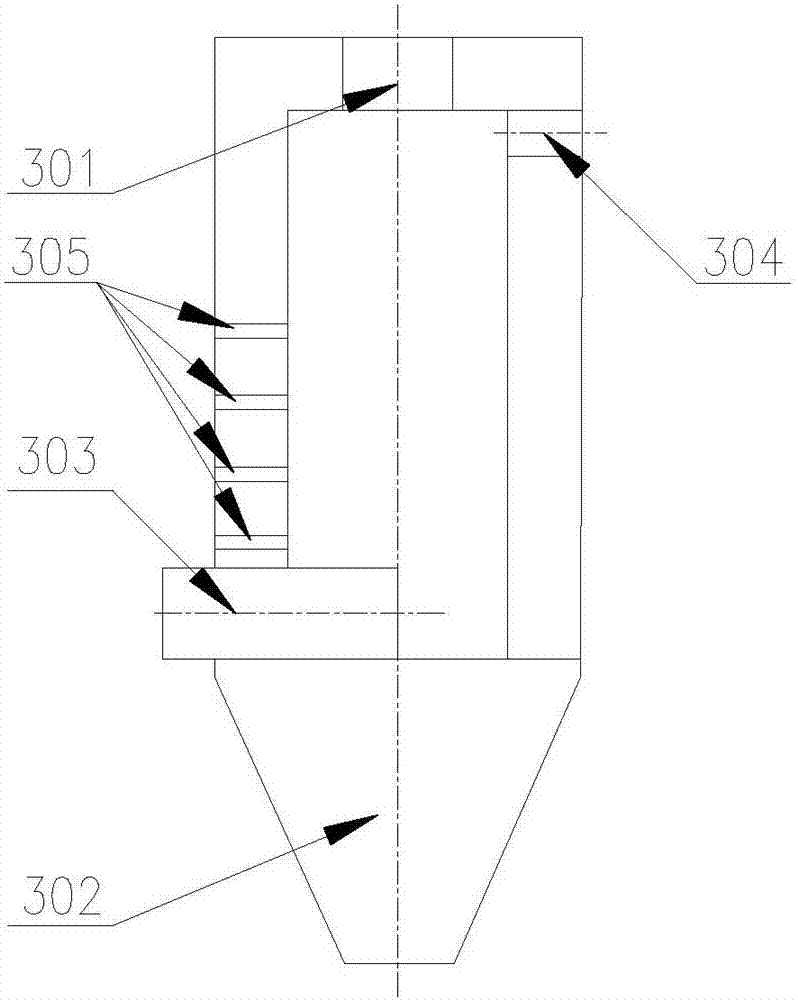

Boiler system utilizing garbage incineration synthesis gas

ActiveCN105444145ABurn fullyIncrease temperatureSteam engine plantsIncinerator apparatusSyngasCombustion chamber

The invention discloses a boiler system utilizing garbage incineration synthesis gas, which has small heat conversion efficiency loss and higher heat recovery efficiency. The boiler system comprises a boiler body, wherein the boiler body is provided with a cyclone combustion chamber, a furnace chamber a and a furnace chamber b, which communicate with one another; a water wall is arranged in the cyclone combustion chamber; a superheater is arranged in the furnace chamber a; an evaporator is arranged is the furnace chamber b; a steam drum is arranged at the top end of the boiler body; a steam-water inlet is formed in the steam drum; the steam drum is connected with a water inlet of the water wall through a first downcomer to output water; the steam drum is connected with a water inlet of the evaporator through a second downcomer to output water; a steam outlet of the water wall and a steam outlet of the evaporator are connected with a steam inlet of the steam drum to reflux high-temperature steam; a saturated steam outlet of the steam drum is connected with a steam inlet of the superheater through a pipeline to input high-temperature steam to the superheater; and a steam outlet of the superheater outputs superheated steam.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

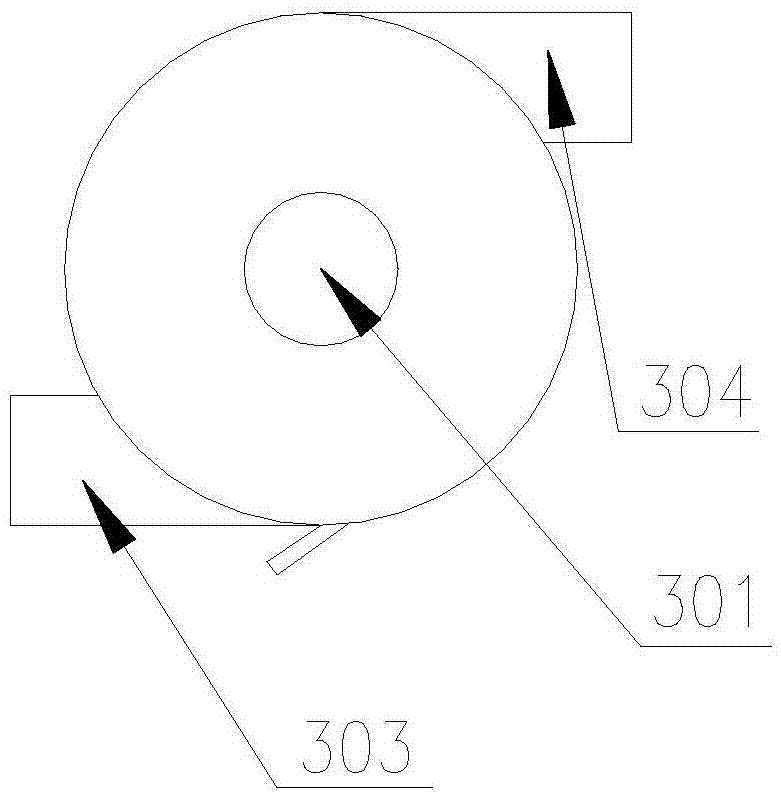

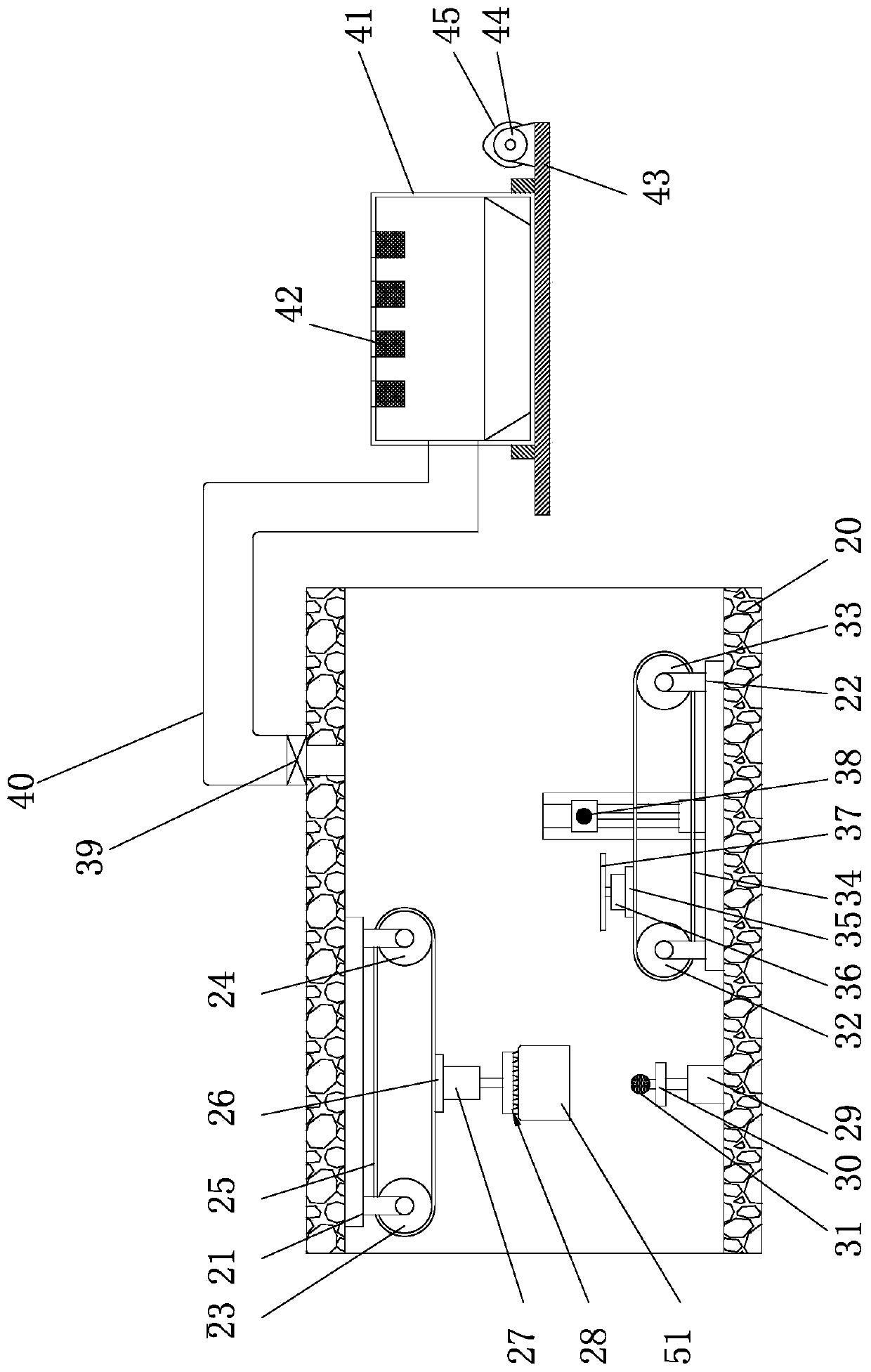

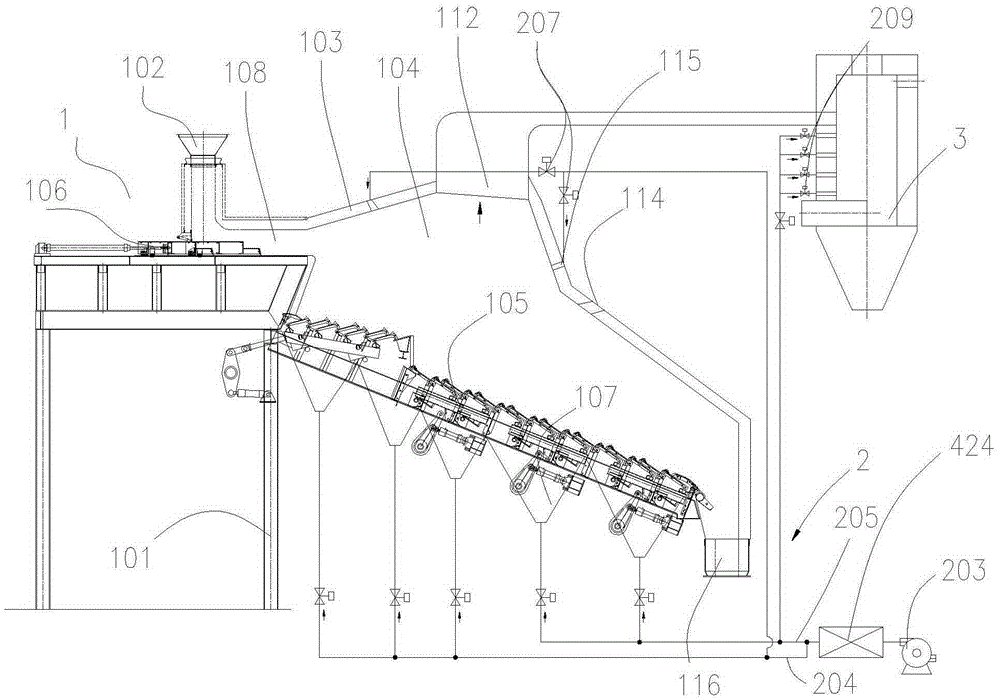

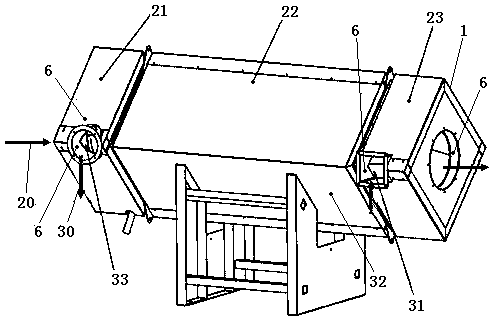

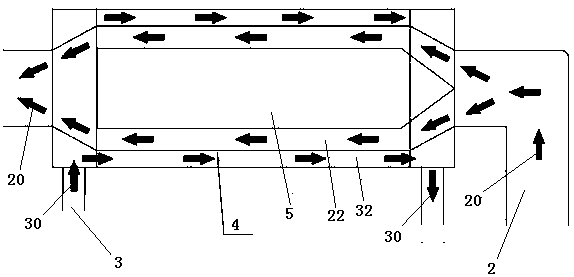

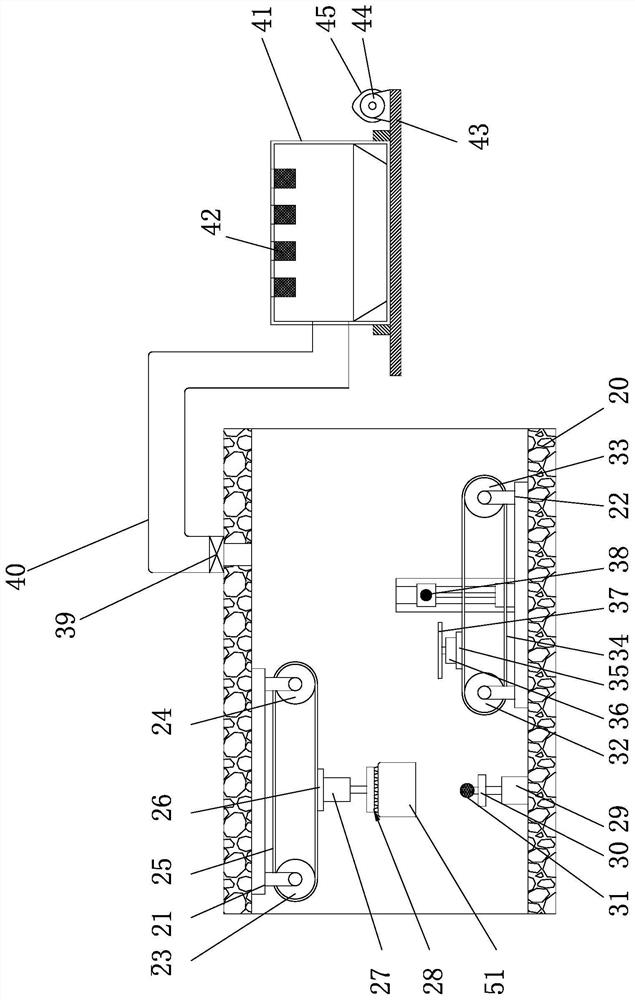

Powder spraying process and device of heat preservation cover

ActiveCN109926250ADry fastRealize the function of one water and two usesHollow article cleaningPretreated surfacesMachiningPowder Spray

The invention provides a powder spraying process and equipment of a heat preservation cover, and belongs to the technical field of machining. The powder spraying equipment of the heat preservation cover comprises a cleaning machine, a powder spraying device and a curing device, the cleaning machine comprises a machine body and a rack, the machine body is arranged on the rack, the machine body is internally provided with a cleaning groove and a liquid accumulation groove, a conveying mechanism is arranged on the rack, the powder spraying device comprises a case, an upper conveying structure anda lower conveying structure are arranged in the case, the heat preservation cover sequentially passes through the upper conveying structure and the lower conveying structure, a first powder sprayingmechanism is arranged on the lower end of the upper conveying structure, at least one set of opposite second powder spraying mechanisms are arranged on the two sides of the lower conveying structure,the case further communicates with a powder recycling device, the upper conveying structure is arranged on the top in the case through an upper support, the lower conveying structure is arranged on the bottom in the case through a lower support, the curing device comprises a curing box, and a preheating cavity, a curing cavity and a cooling cavity are formed in the curing box. The heat preservation cover can be kept clean and is subjected to non-dead-corner powder spraying, and in addition, during curing, powder falling is not prone to happening.

Owner:浙江东蓝机电有限公司

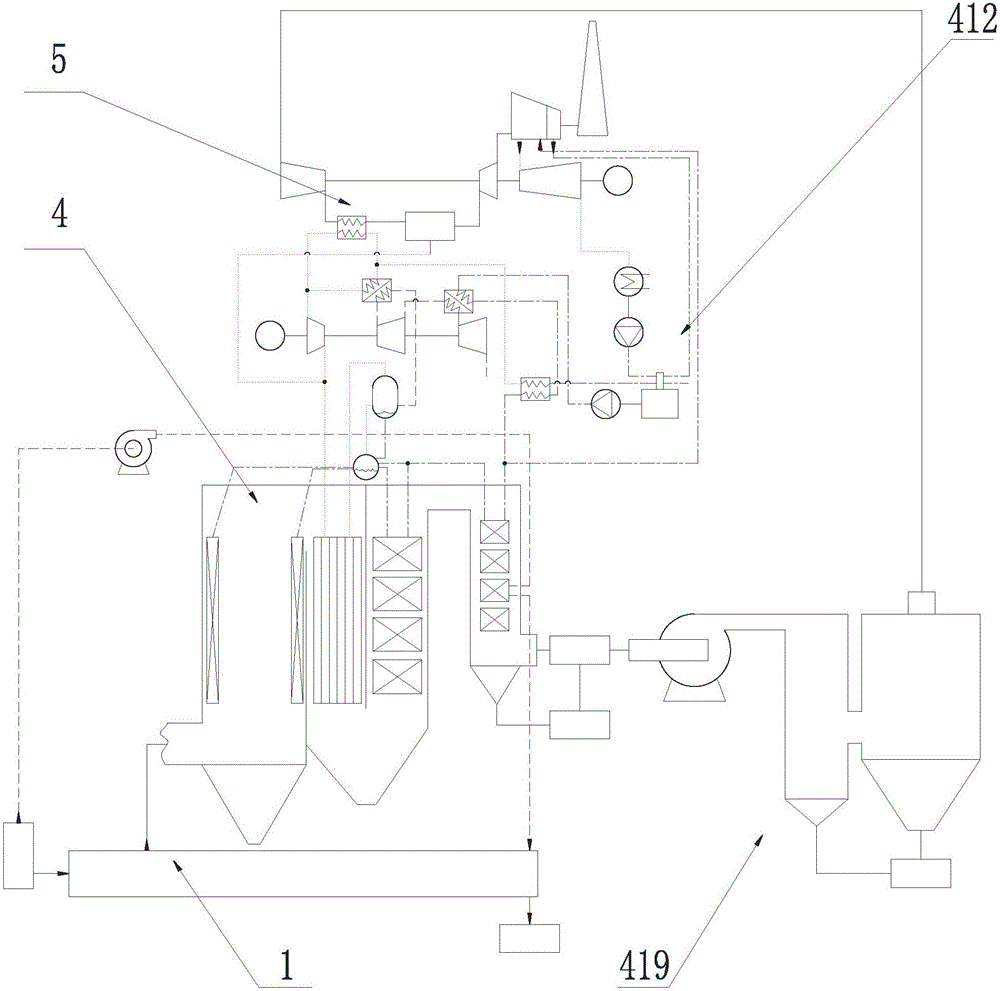

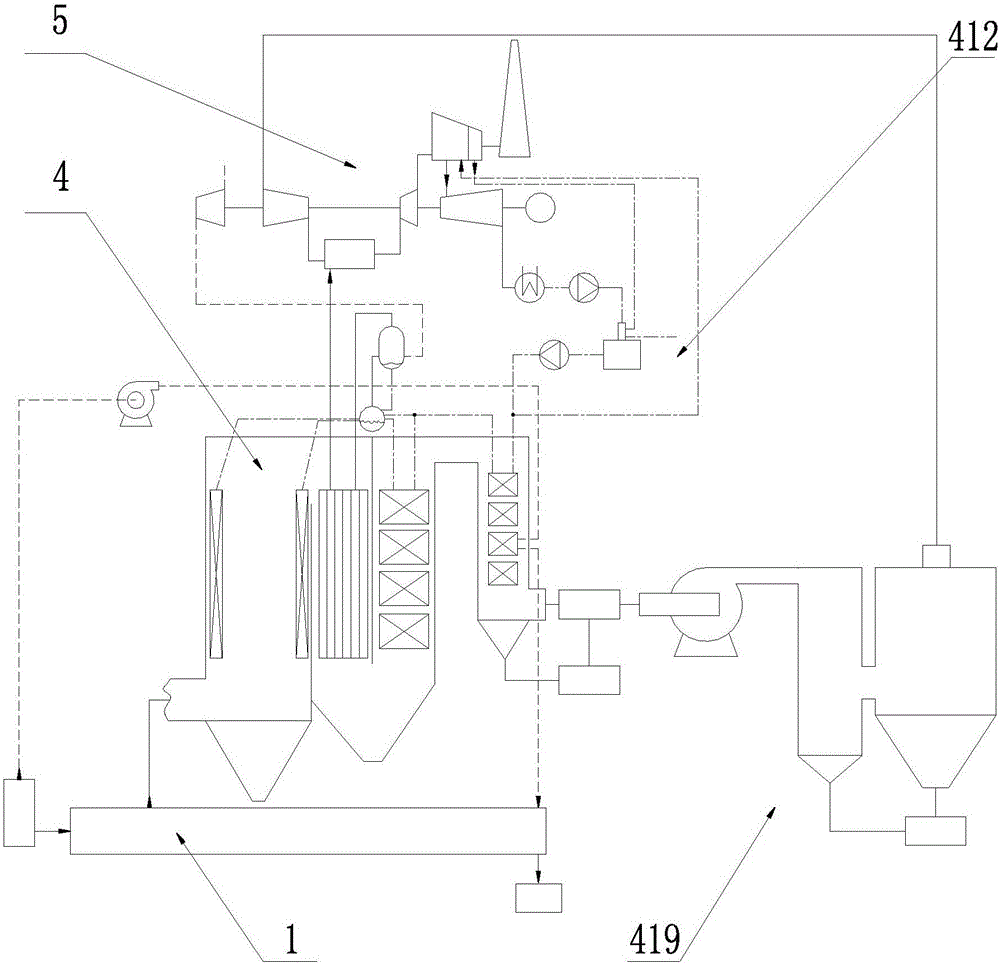

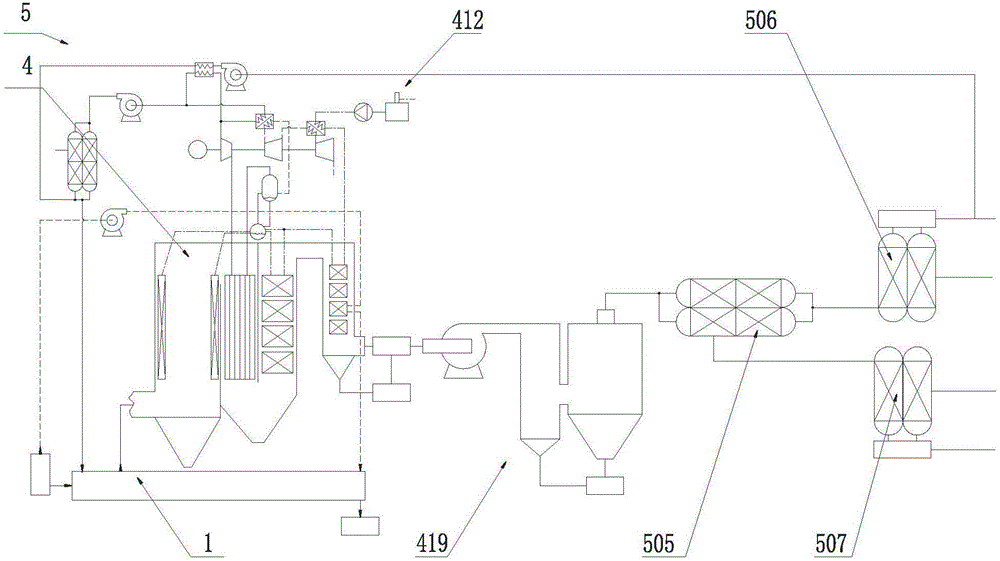

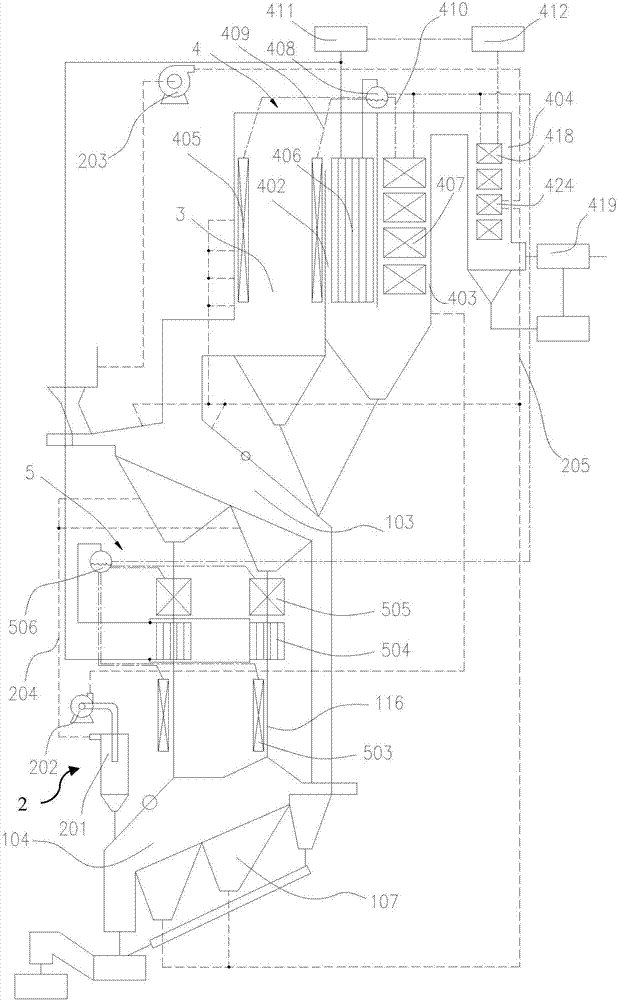

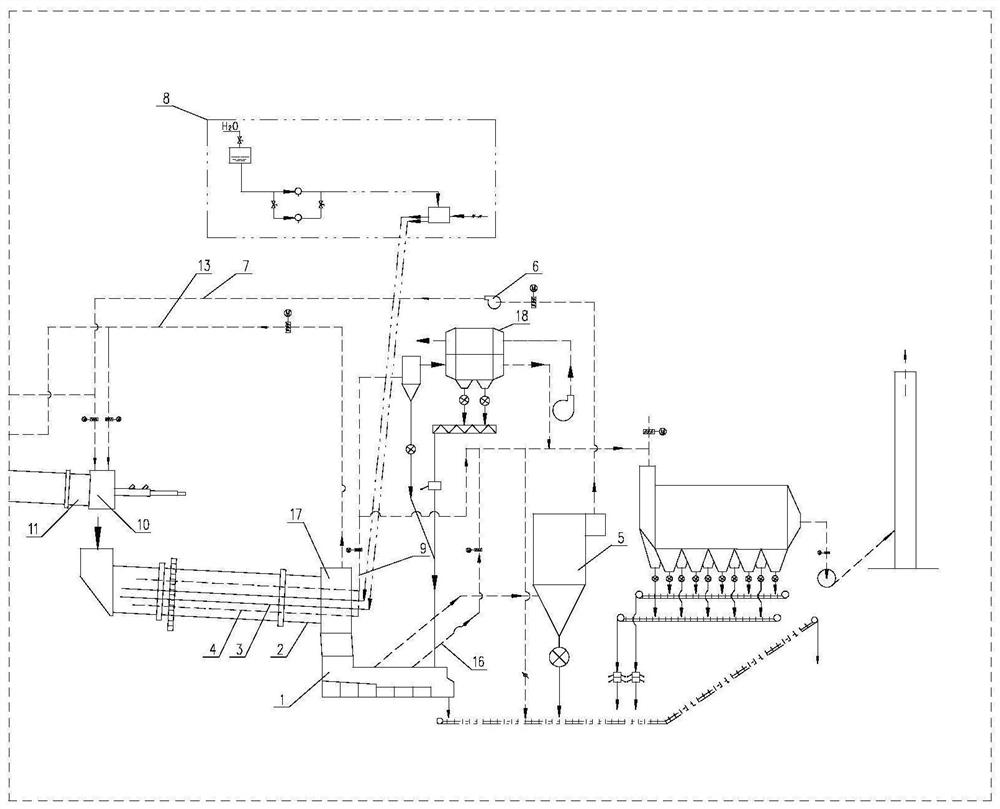

Garbage gasified fuel gas and steam turbine combined power generation system adopting multi-stage heat exchange mode

ActiveCN106224036AEmission reductionImprove recycling efficiencyGas turbine plantsSolid fuel combustionCombustion chamberGas compressor

The invention discloses a garbage gasification fuel gas and steam turbine combined power generation system adopting a multi-stage heat exchange mode. The garbage gasified fuel gas and steam turbine combined power generation system comprises a garbage gasification system, a boiler system and a power generation system; the power generation system comprises a mixer, an air compressor, a synthesized smoke gas compressor, a synthesized smoke gas combustion chamber, a turbine a, a turbine b, a steam turbine, a power generator a, a power generator b and a waste heat boiler. A heating channel of a synthesized gas steam-gas heat exchanger, a heating channel of an air steam-gas heat exchanger and a heating channel of a steam-water heat exchanger are connected between a gas outlet of the turbine a and a water feeding hole of a water feeding input system. A heated channel of a gas-water heat exchanger is connected between a low-pressure air compressor and a high-pressure air compressor. According to the garbage gasification fuel gas and steam turbine combined power generation system adopting the multi-stage heat exchange mode disclosed by the invention, large-scale garbage continuous gasification treatment is realized, garbage treatment capacity is greater, heat recycling efficiency is high, and emission of pollutants can be effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

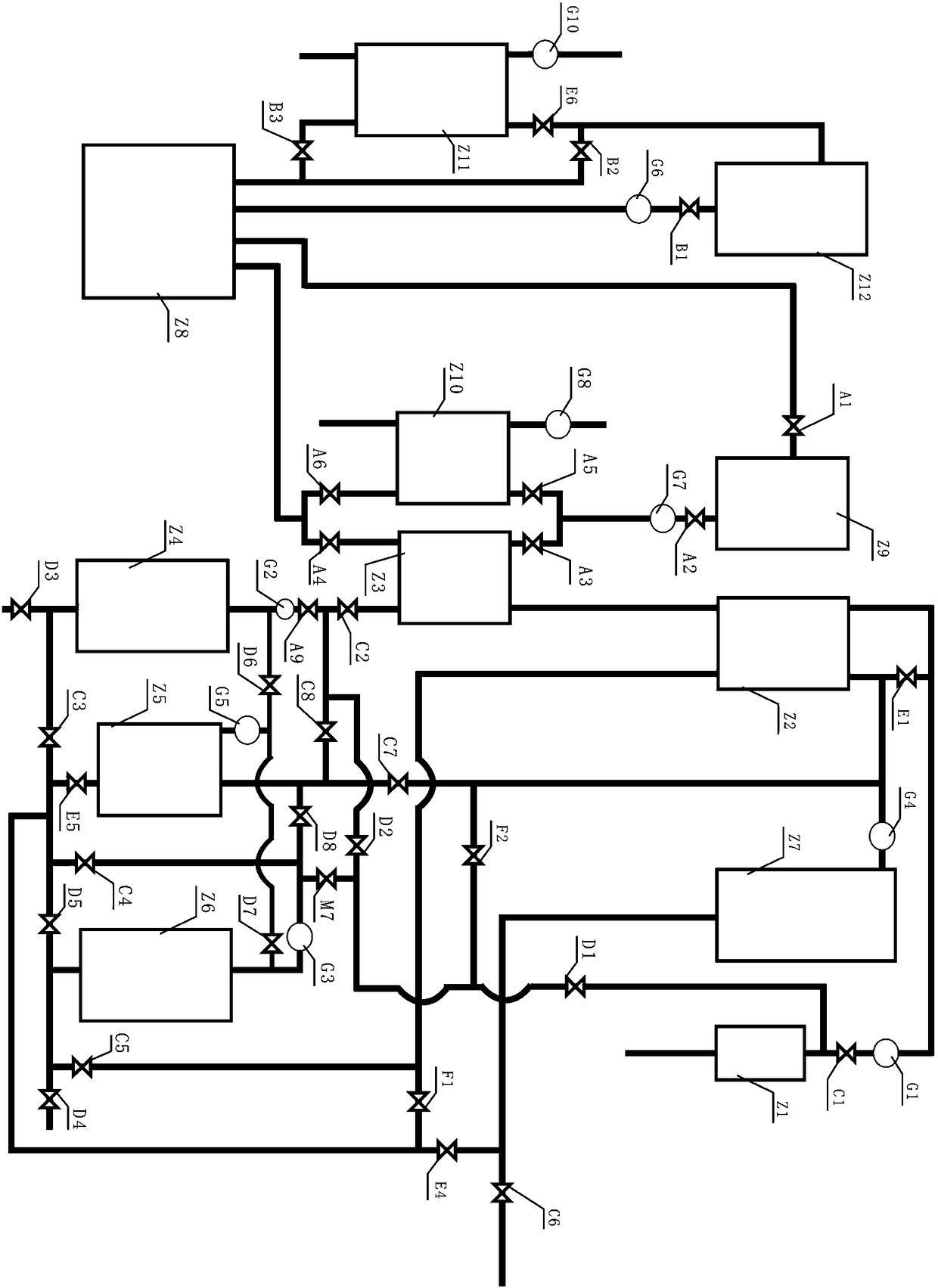

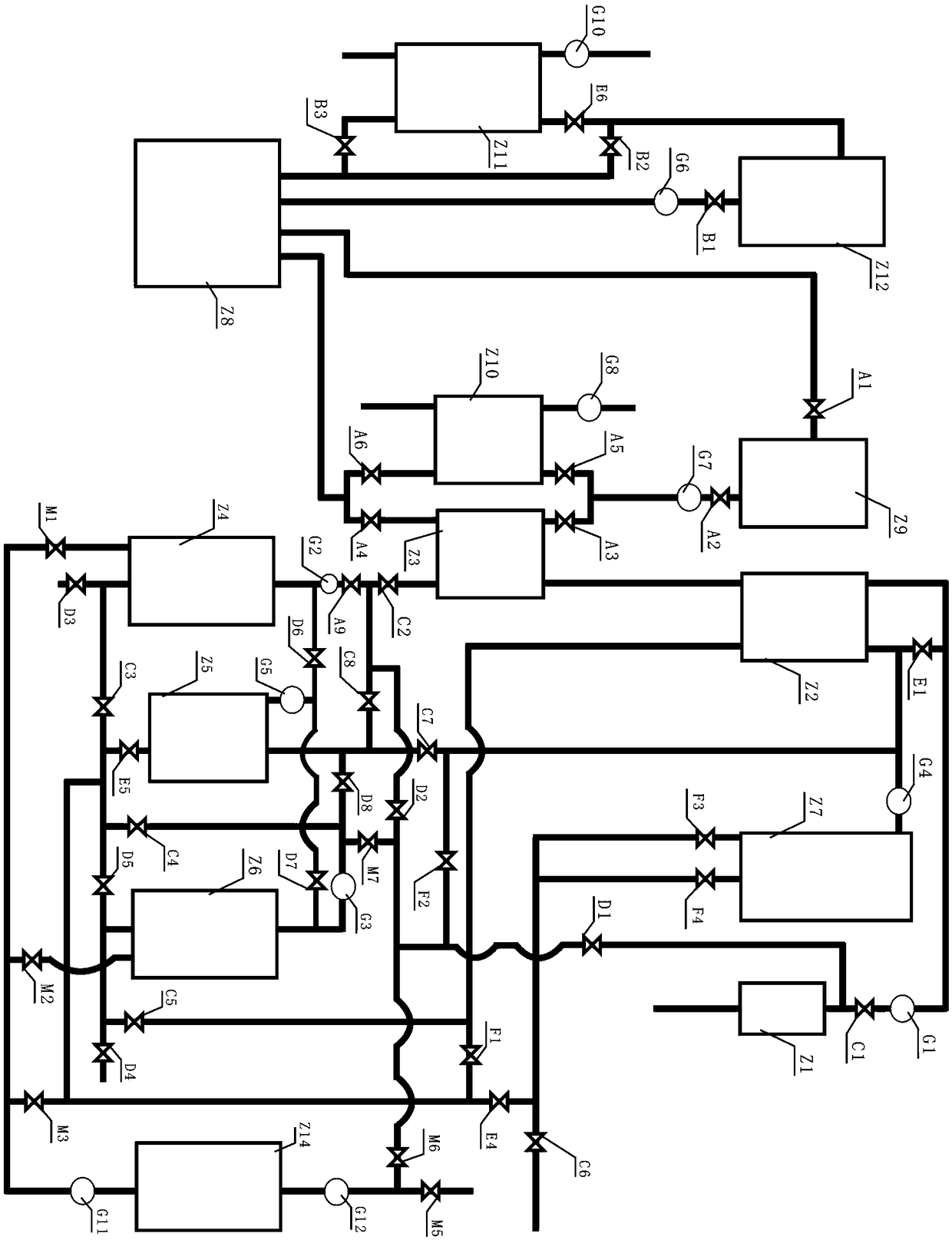

Air conditioner water cold storage system

InactiveCN106969452AReduce cooling lossImprove work efficiencyMechanical apparatusSpace heating and ventilation safety systemsIce waterEngineering

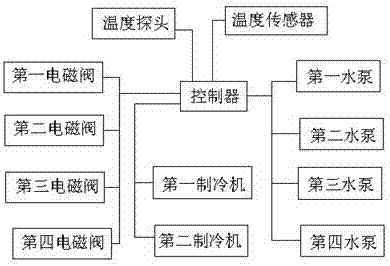

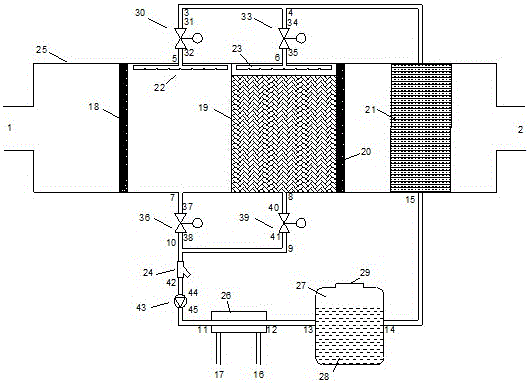

The invention discloses an air conditioner water cold storage system. The air conditioner water cold storage system comprises an air conditioner fan coil, a water pool, a first ice water storage tank, a second ice water storage tank, a water replenishing tank and a controller. The water inlet end of the air conditioner fan coil is provided with a water inlet pipeline. The water outlet end of the air conditioner fan coil is provided with a water outlet pipeline. The air conditioner fan coil is provided with a circulation pipeline. A first pipeline and a second pipeline are connected between the water inlet pipeline and the water outlet pipeline. The first ice water storage tank is arranged on the first pipeline. The second ice water storage tank is arranged on the second pipeline. A water return tank connected with the water outlet end of the air conditioner fan coil through a pipeline is arranged in the water pool. The water inlet pipeline is provided with a second water pump. The water outlet pipeline is provided with a third water pump and a fourth electromagnetic valve. A temperature sensor is arranged at the water outlet end of the air conditioner fan coil. A temperature probe is arranged in the air conditioner fan coil. The temperature sensor and the temperature probe are both connected with the controller. The water replenishing tank is connected with the first pipeline and the second pipeline through water pipes. The air conditioner energy consumption is lowered, and heat recycling of hot water obtained after heat exchange is achieved.

Owner:上海碳誉节能环保科技有限公司

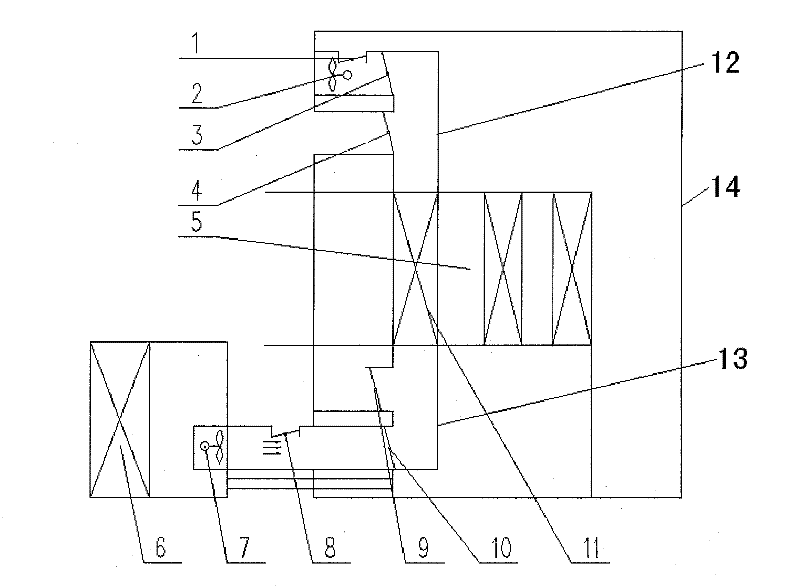

Air dewetting and dedusting integrated device and dewetting and dedusting method

ActiveCN106091132AAchieve dust removalRealize integrationEnergy recovery in ventilation and heatingMechanical apparatusParticulatesEngineering

The invention discloses an air dewetting and dedusting integrated device. The air dewetting and dedusting integrated device comprises a box, a first water stopping plate, a second water stopping plate, a dewetting device, a dedusting device and a connecting device, wherein the first water stopping plate, the second water stopping plate, the dewetting device and the dedusting device are arranged inside the box; the connecting device is arranged outside the box; the first water stopping plate and the second water stopping plate are fixedly connected to the inner wall of the box; the first water stopping plate is close to an air feeding end of the box; the dewetting device and the dedusting device are positioned between the first water stopping plate and the second water stopping plate; compared with the dewetting device, the dedusting device is closer to the air feeding end of the box; and the connecting device is respectively connected with the dewetting device and the dedusting device, so that a circulating loop is formed. According to the device and the dewetting and dedusting method, two circulations are carried out by the same solution, dewetting, dedusting and reheating are organically combined, therefore, a system has the advantages of energy conservation and environmental protection on solution dewetting, meanwhile, extra filter equipment is not required, but a function of removing particulate matters and pollutants in air can be fulfilled, air supply resistance of the system is reduced, and energy is saved.

Owner:NANJING TECH UNIV

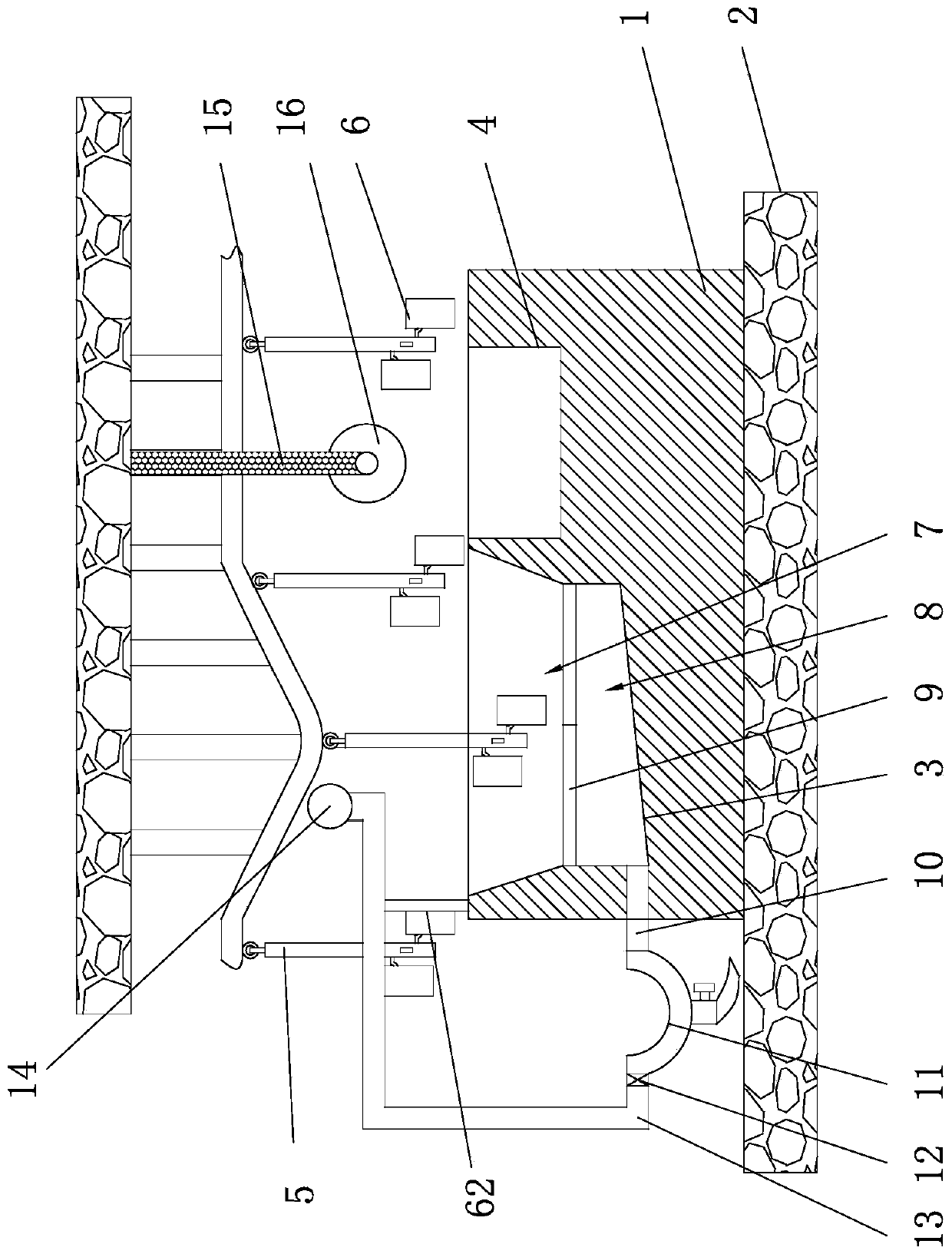

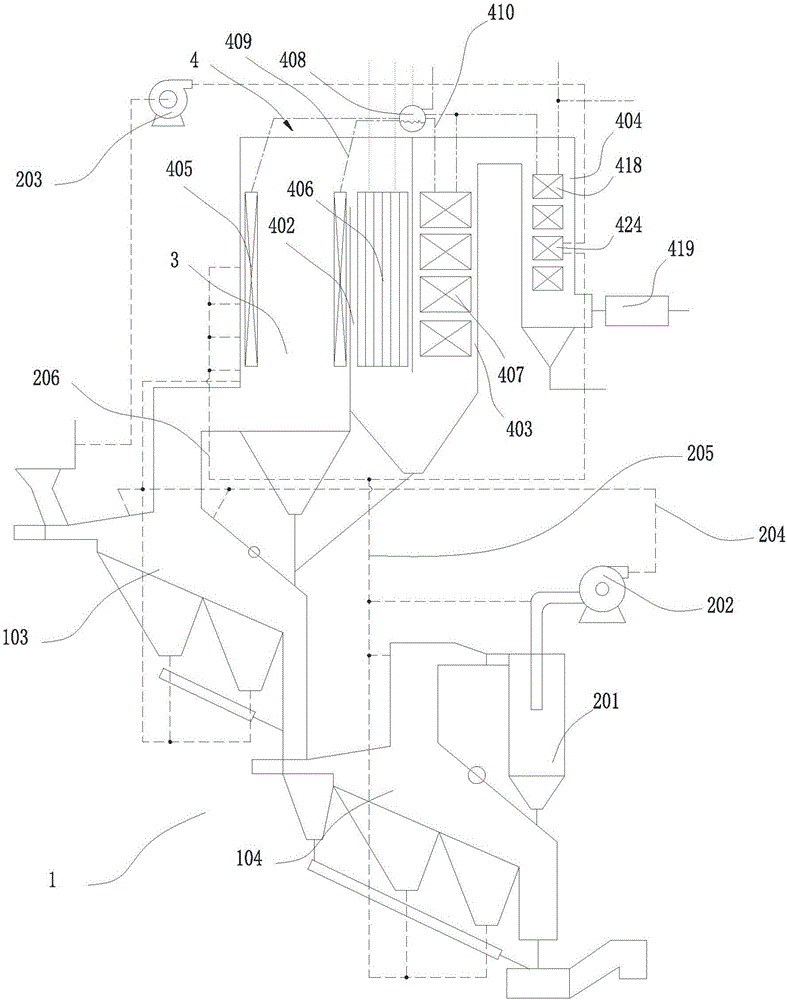

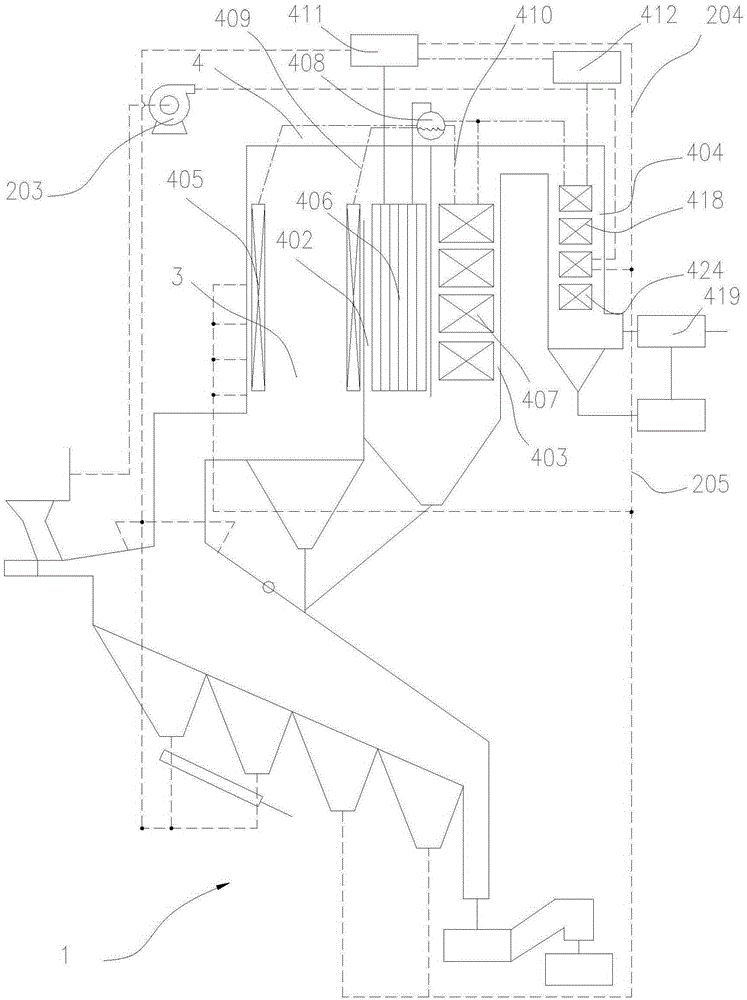

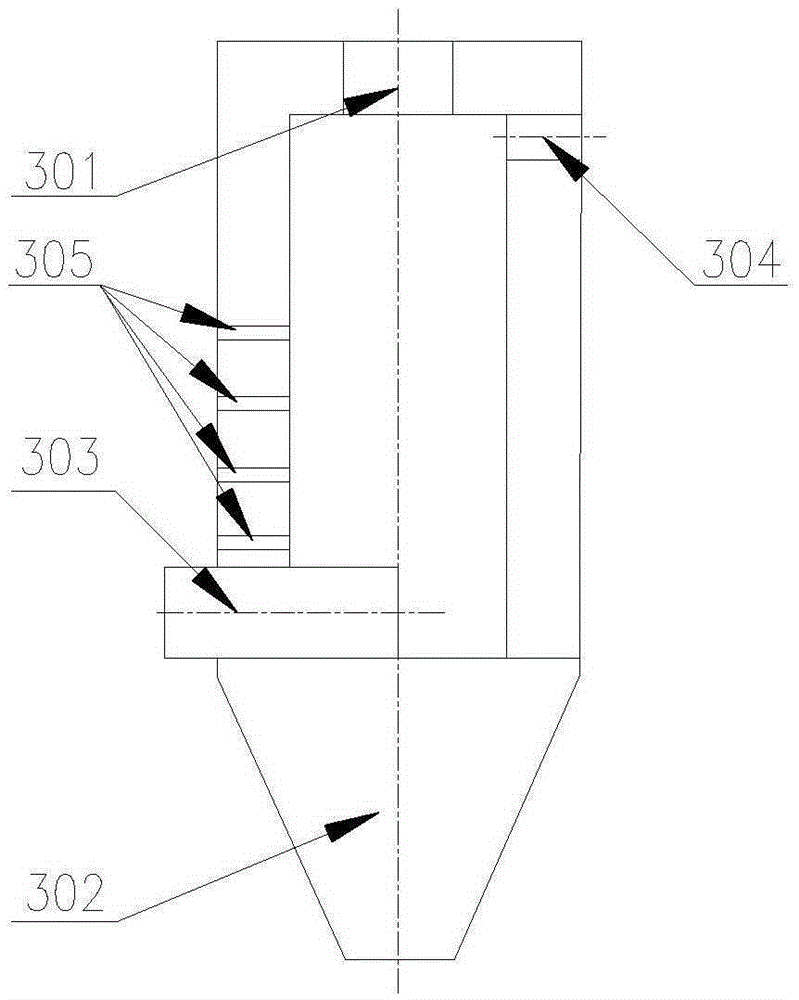

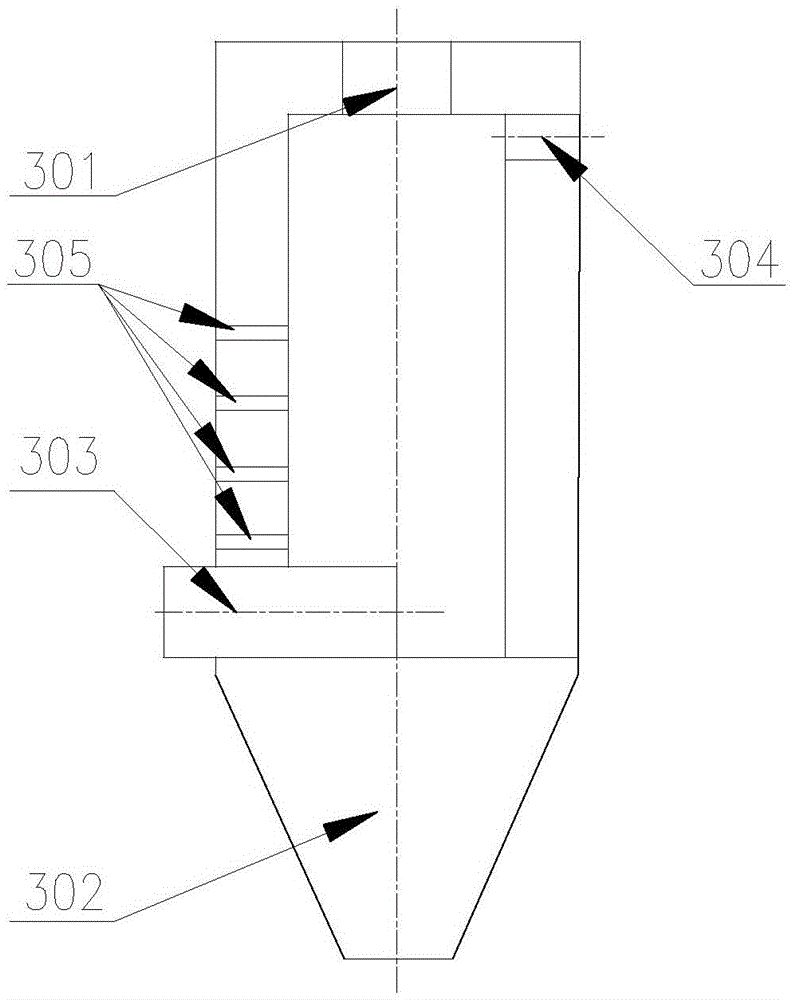

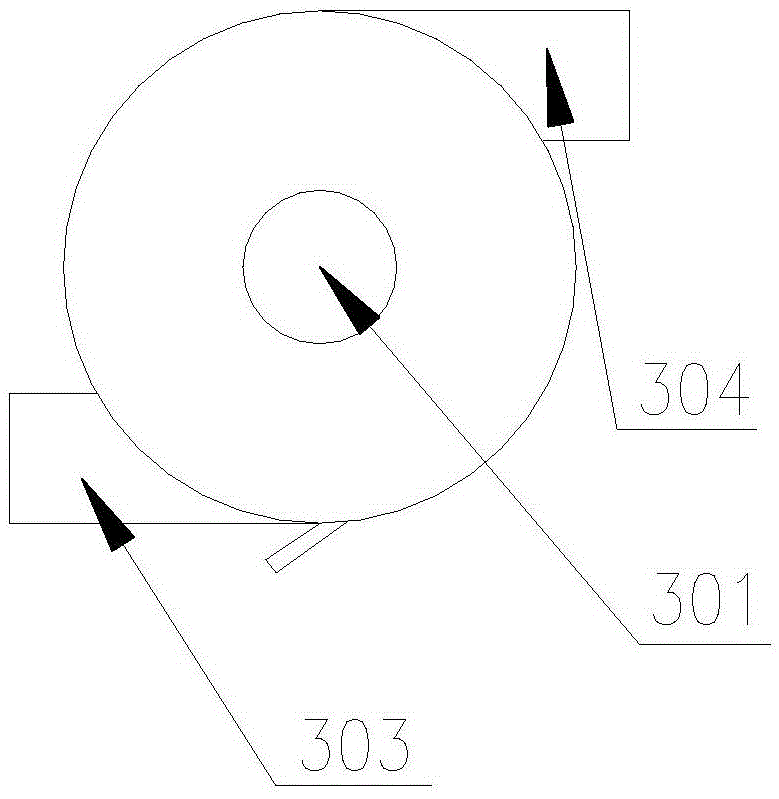

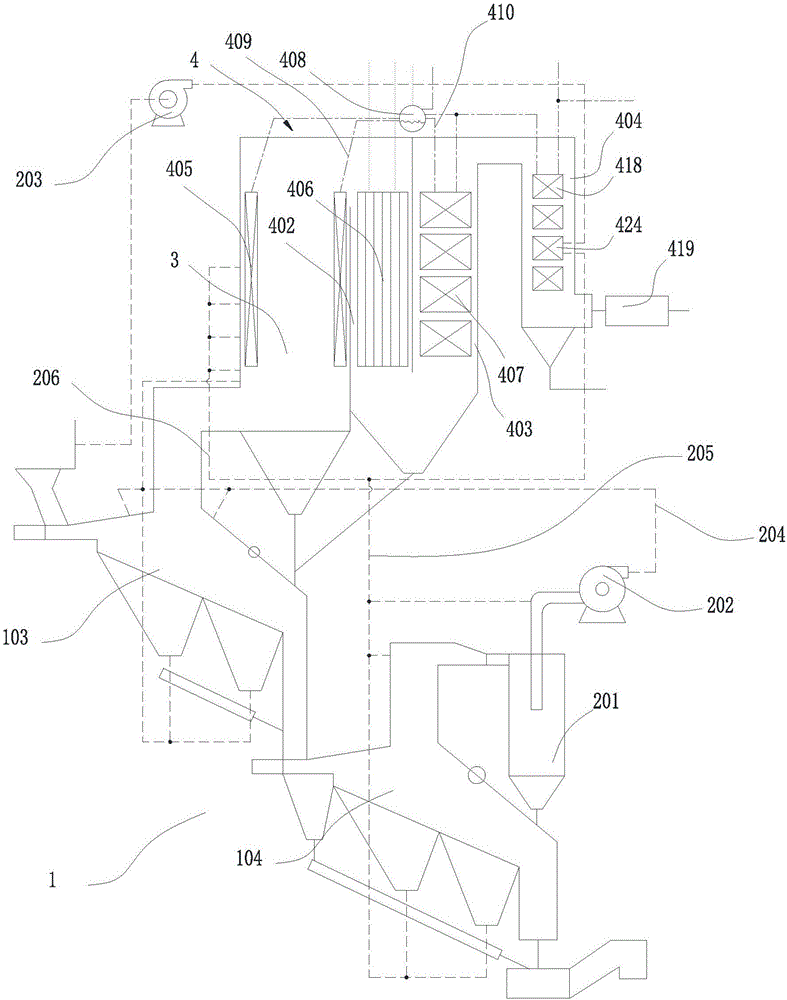

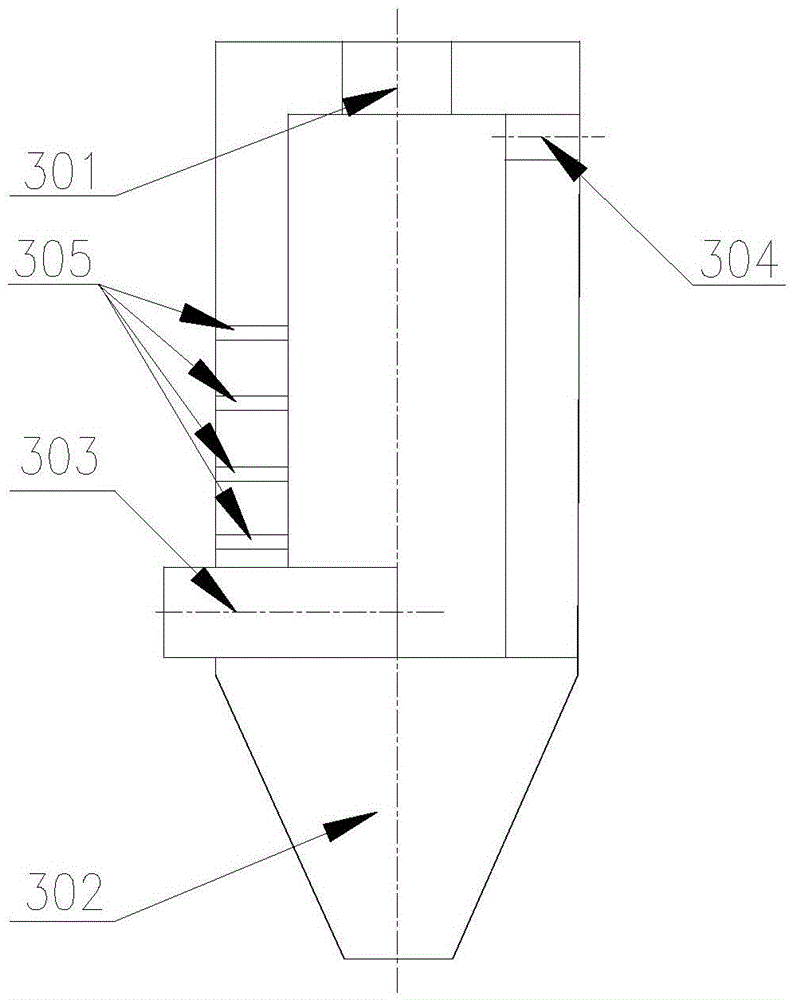

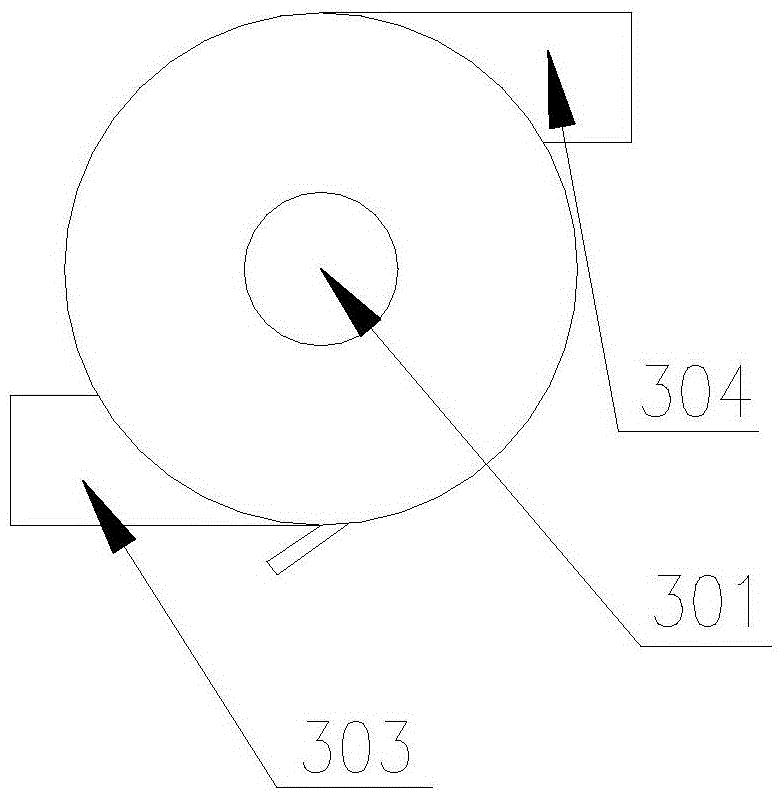

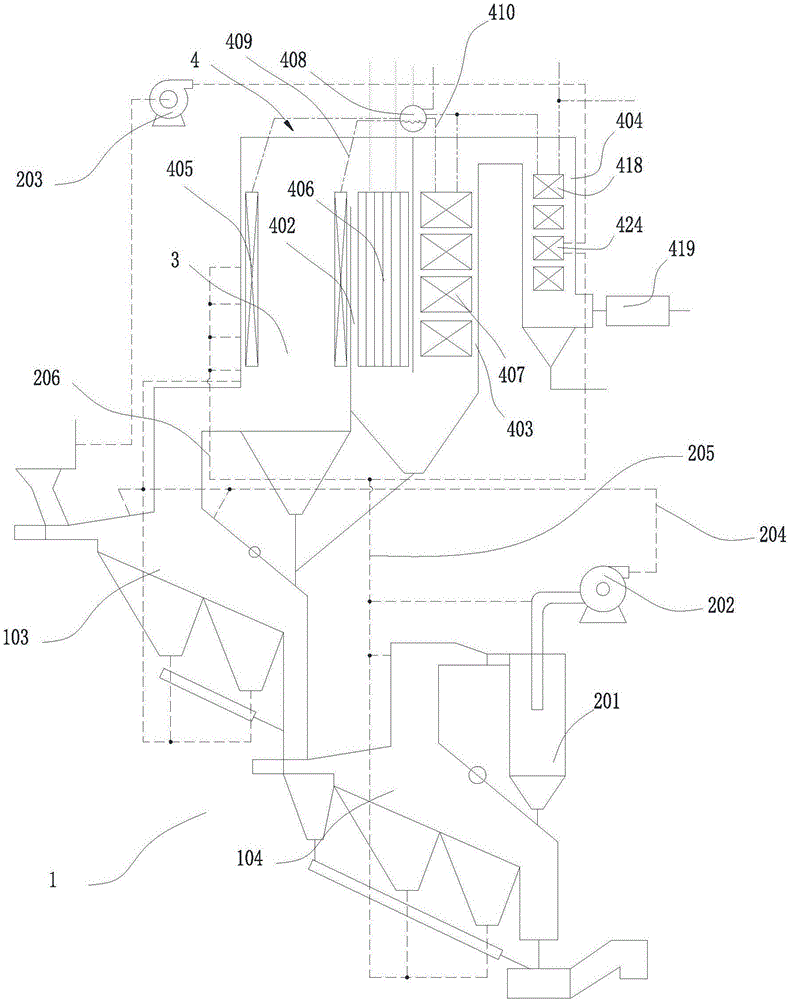

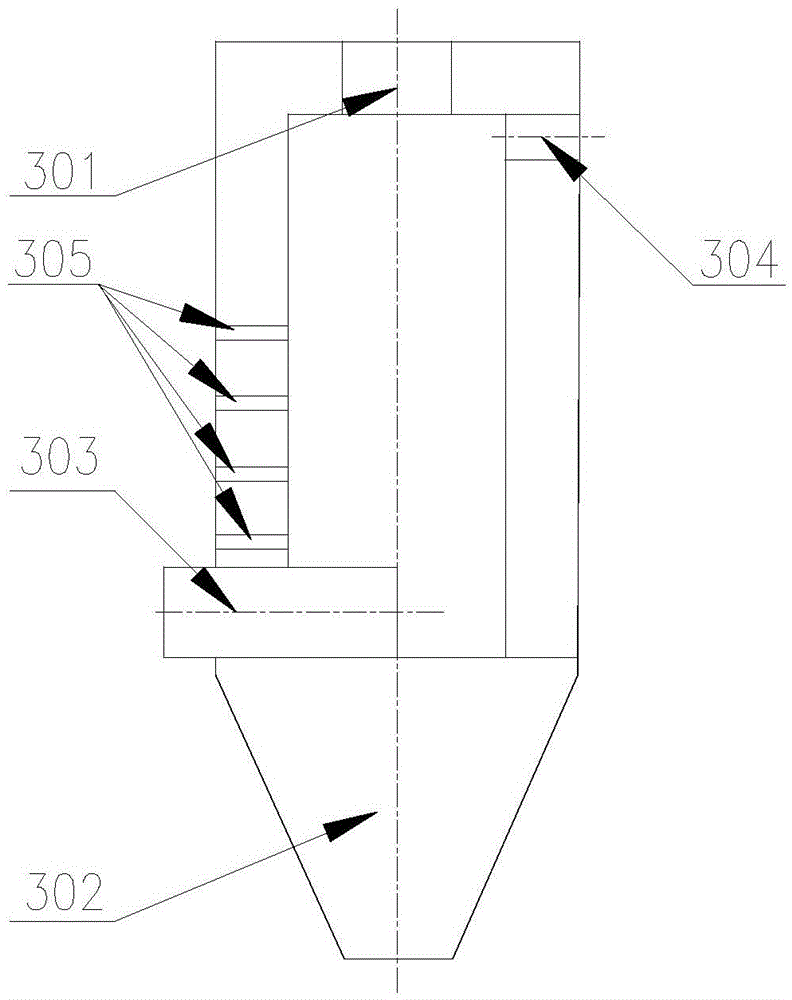

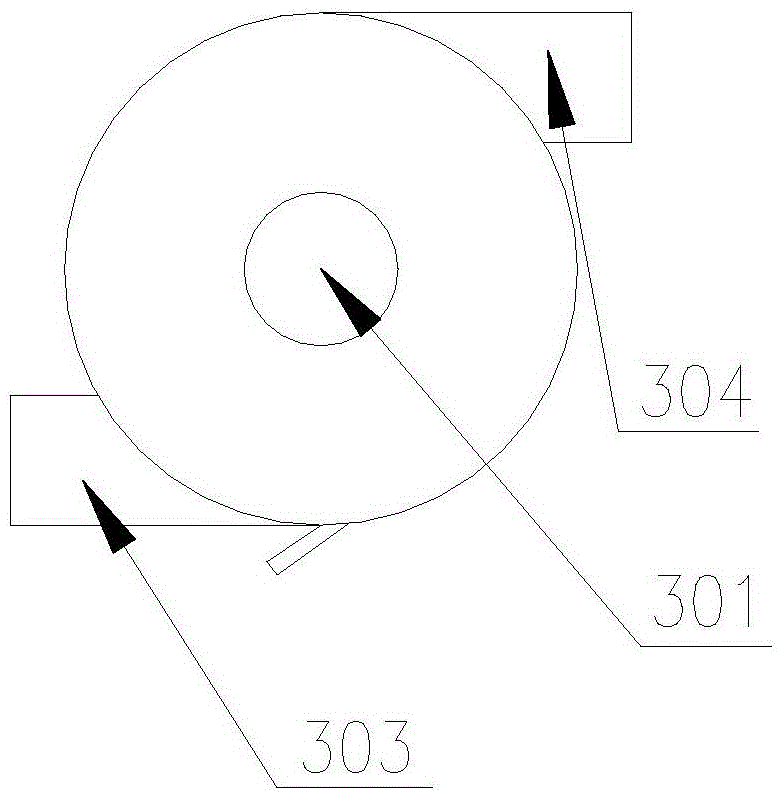

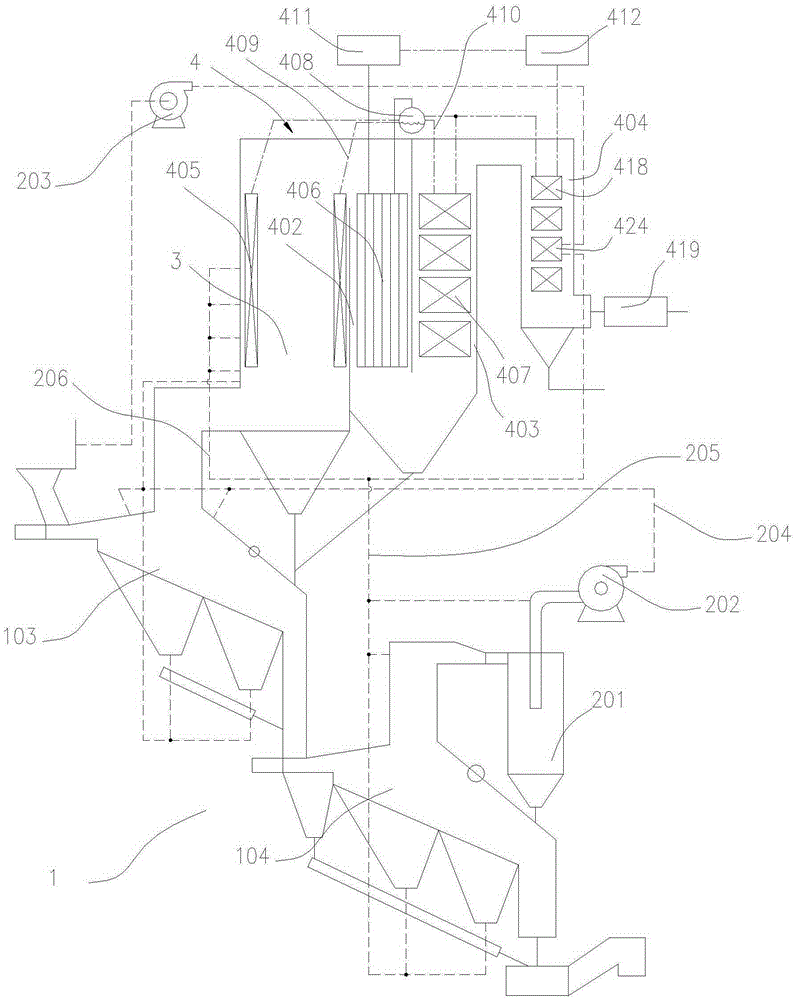

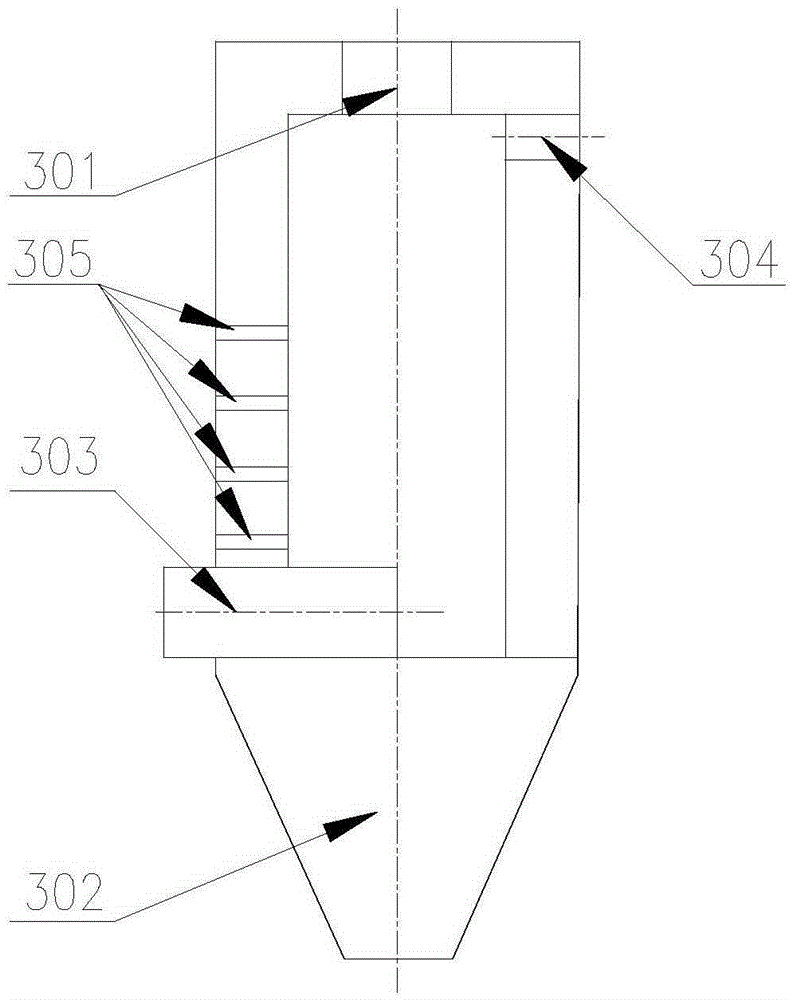

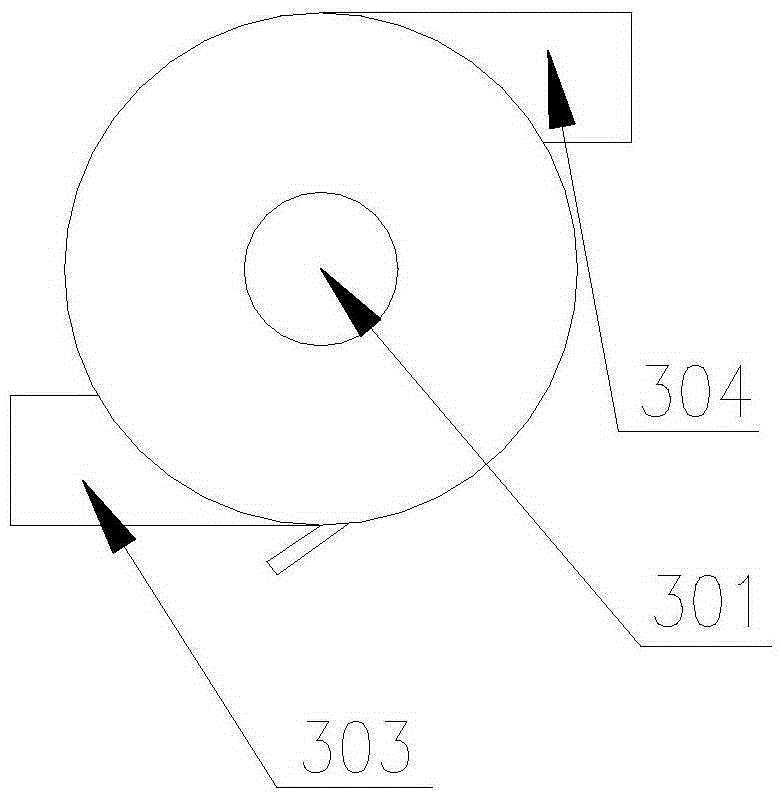

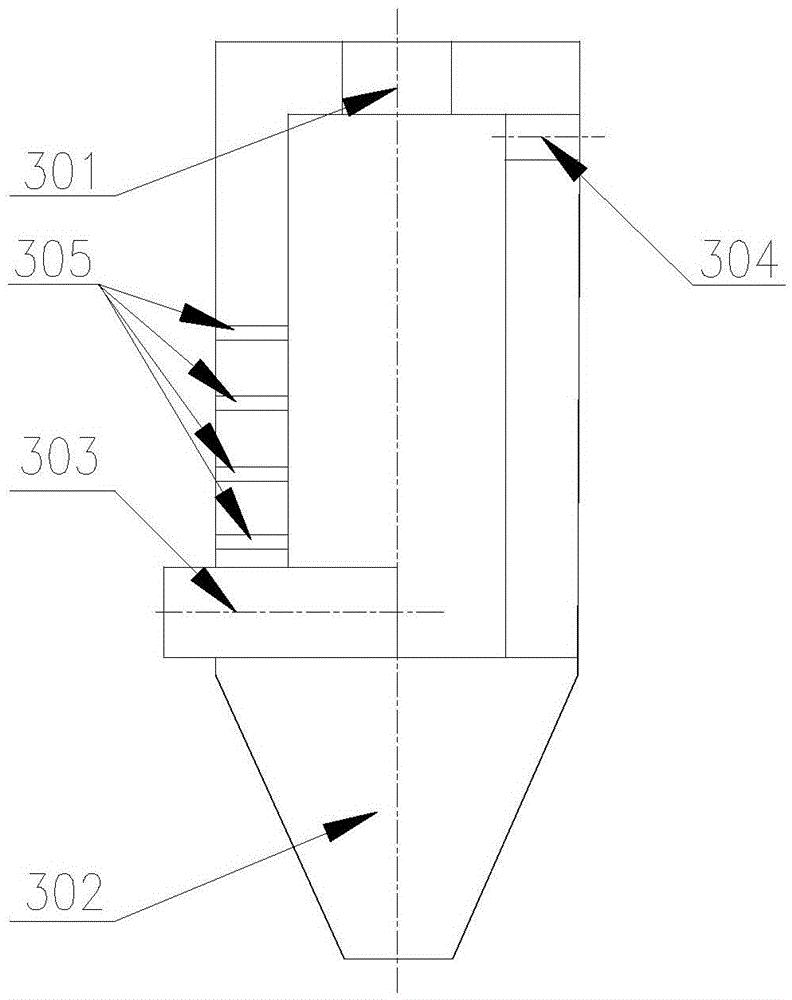

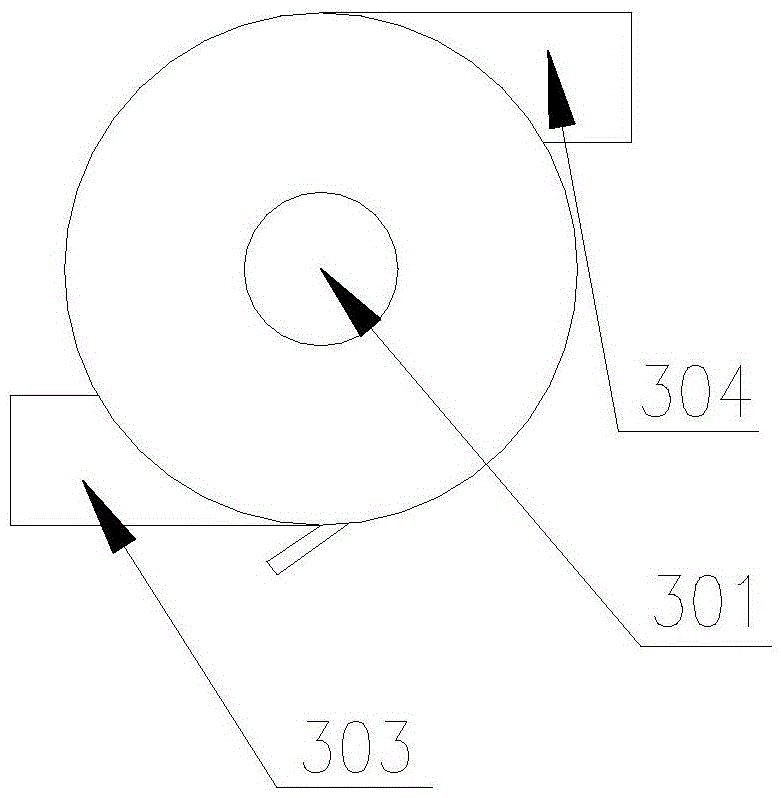

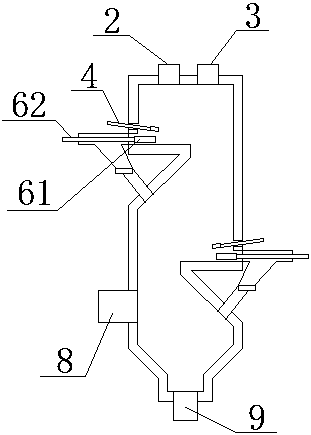

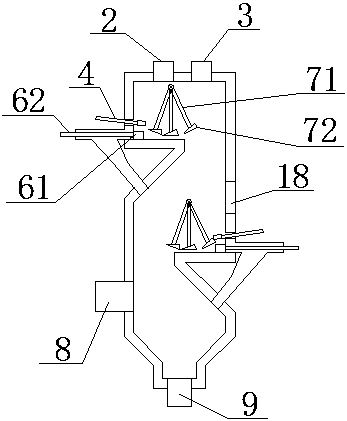

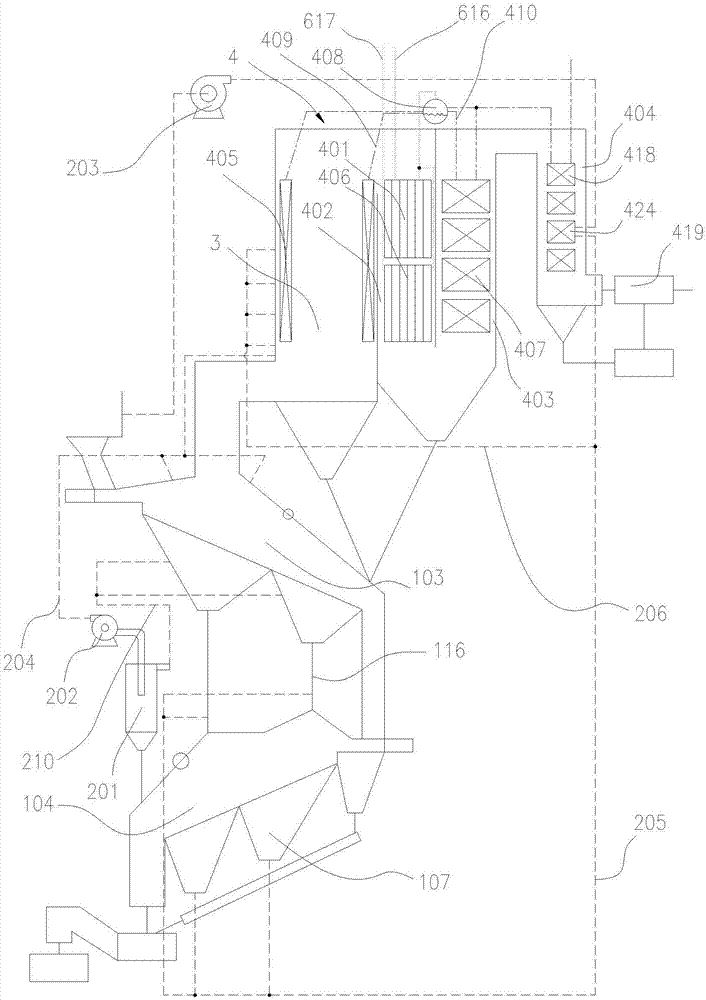

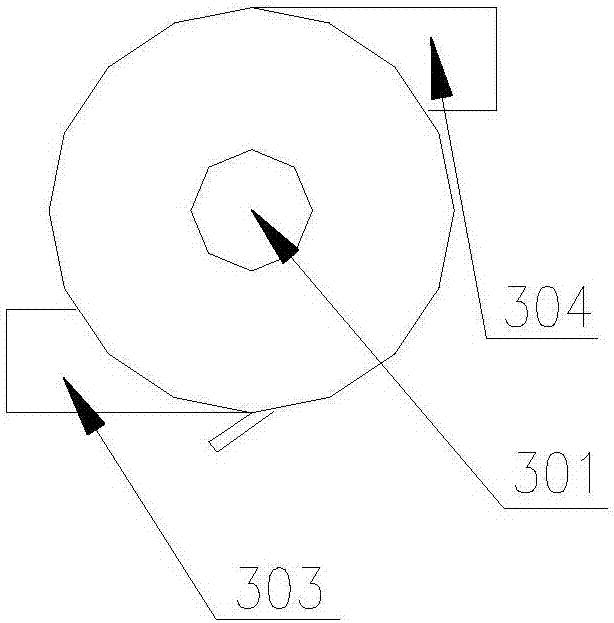

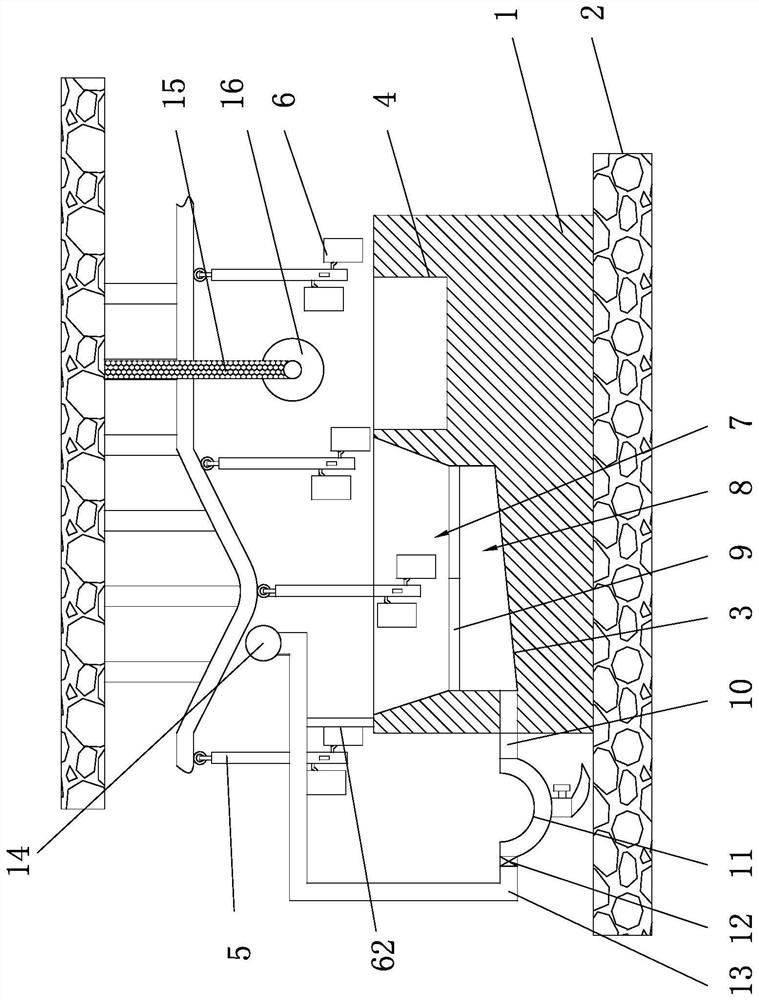

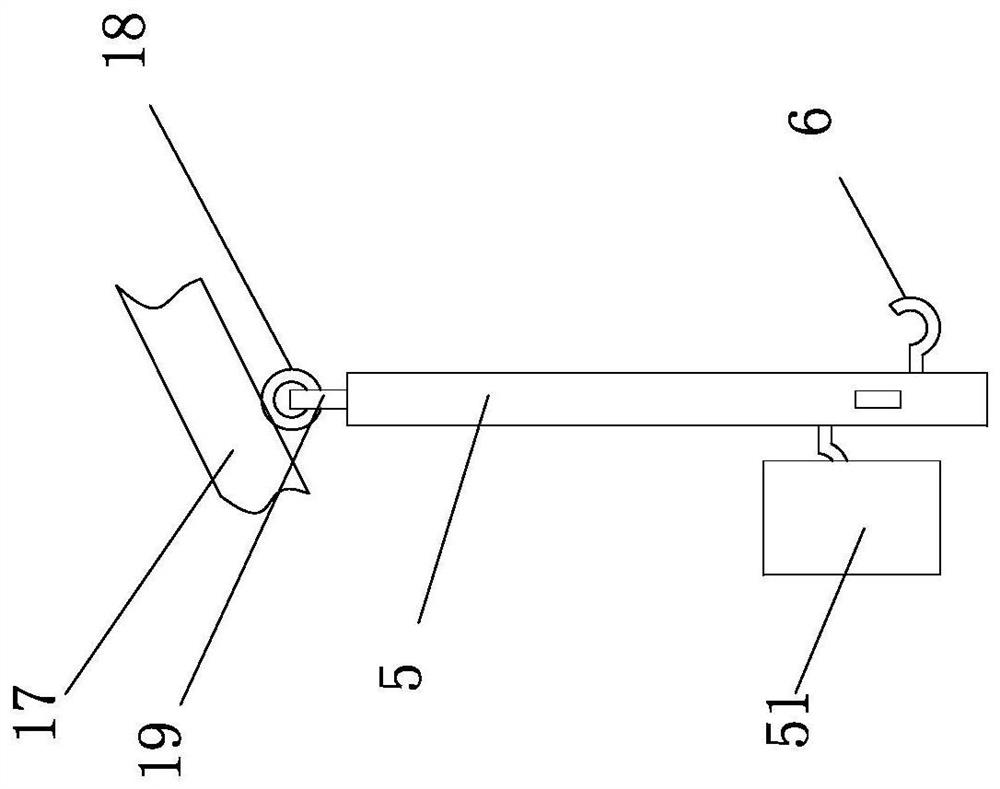

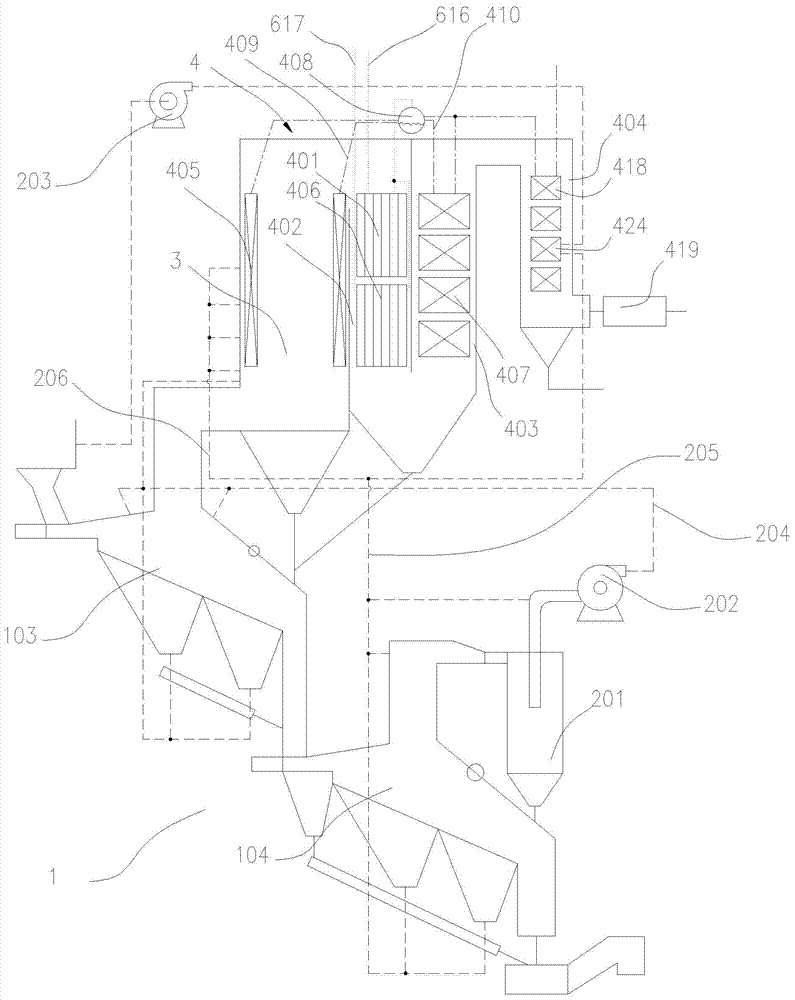

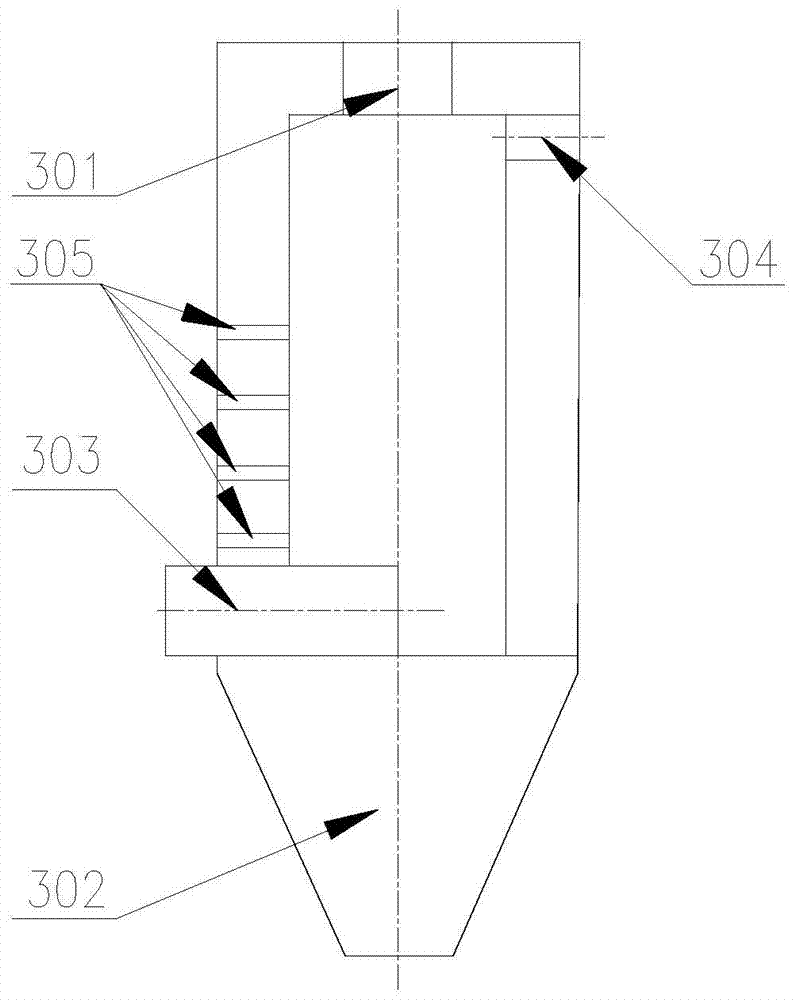

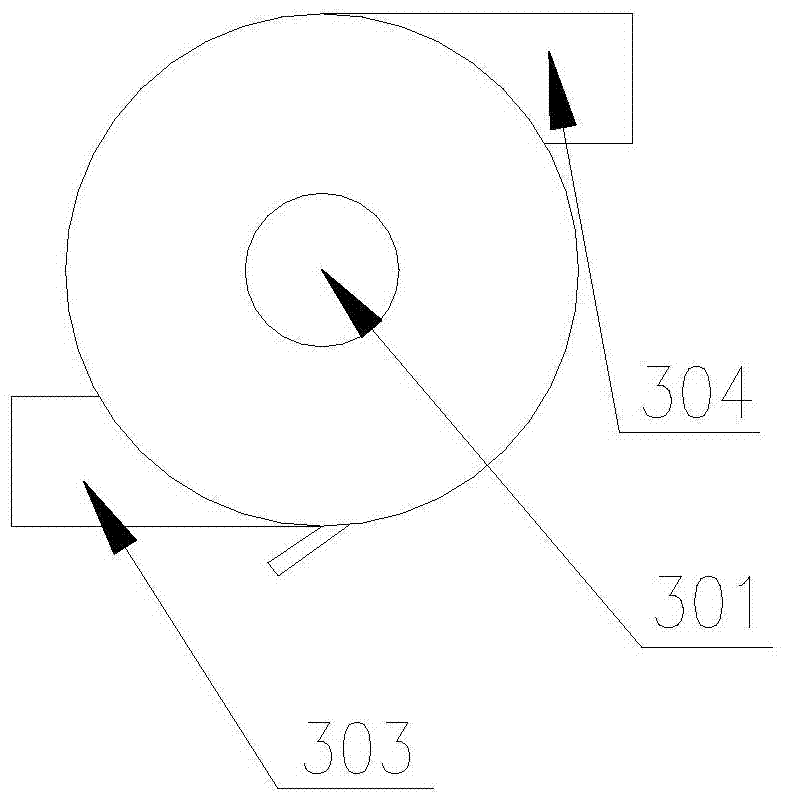

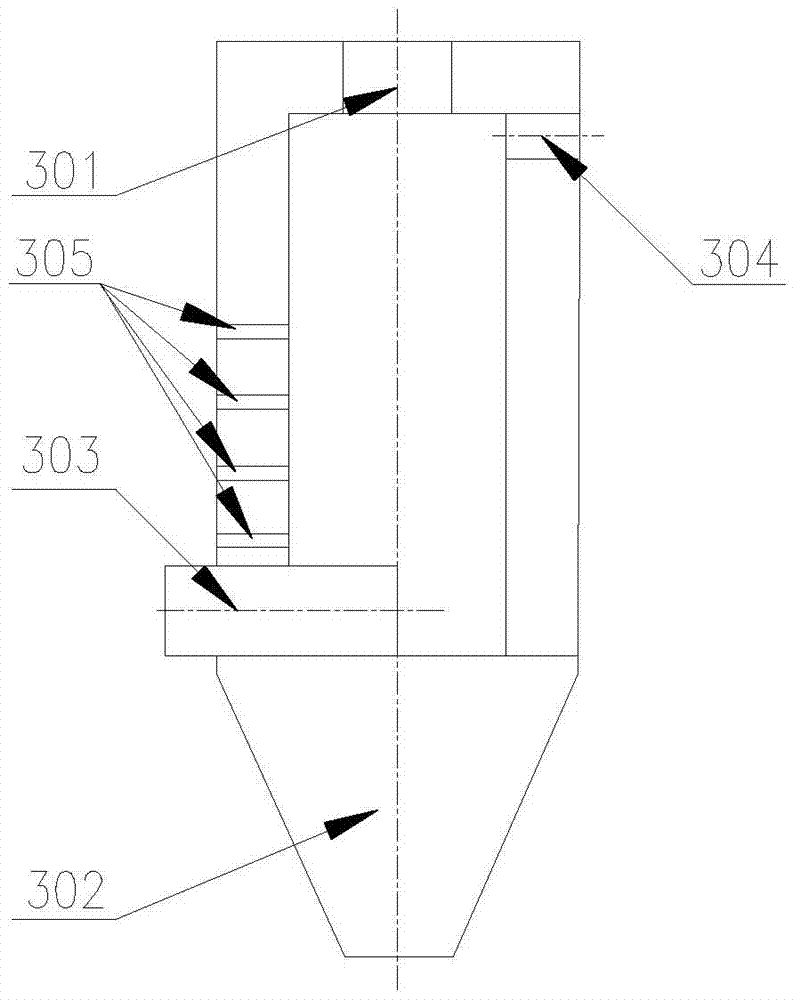

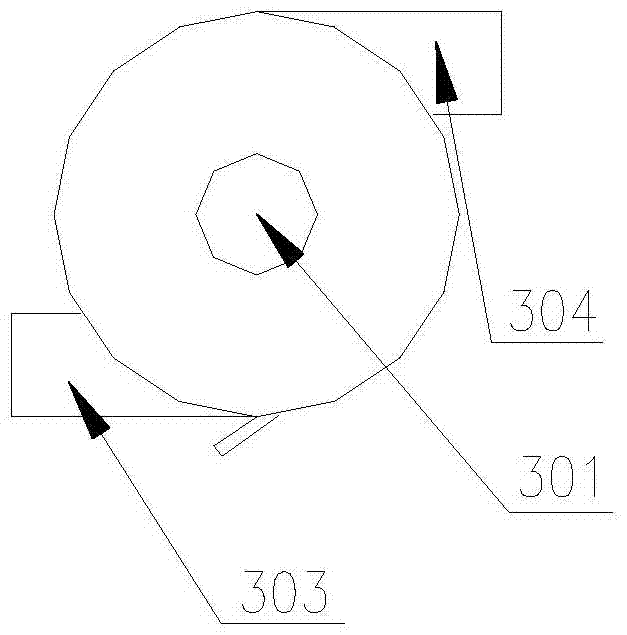

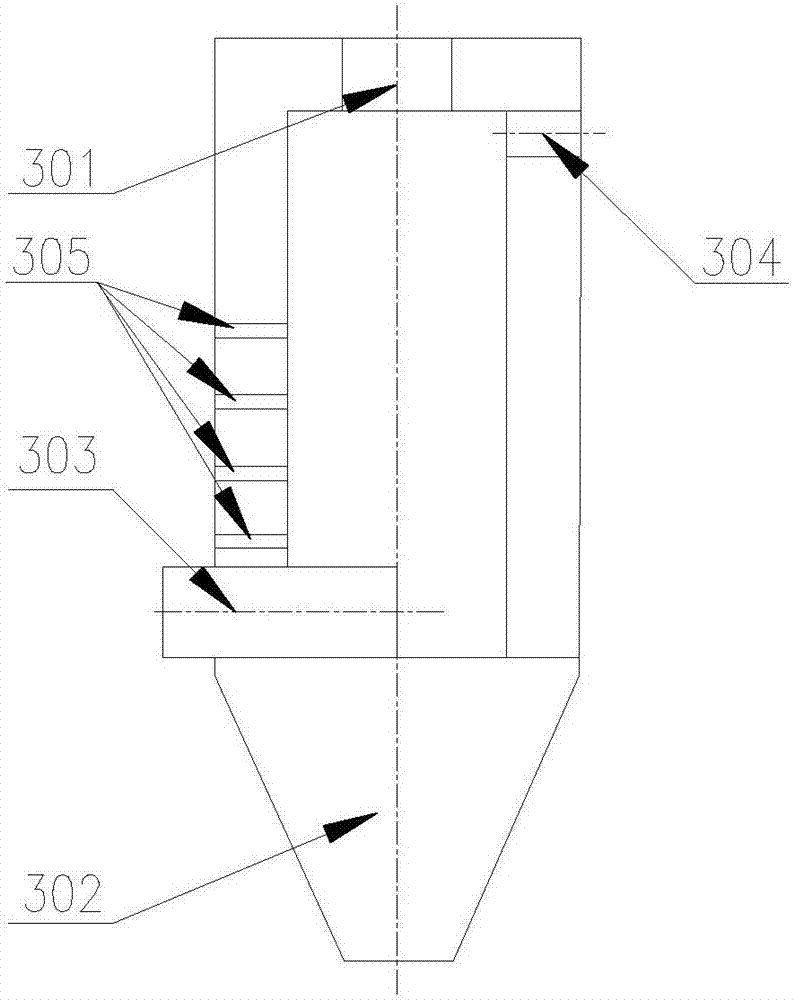

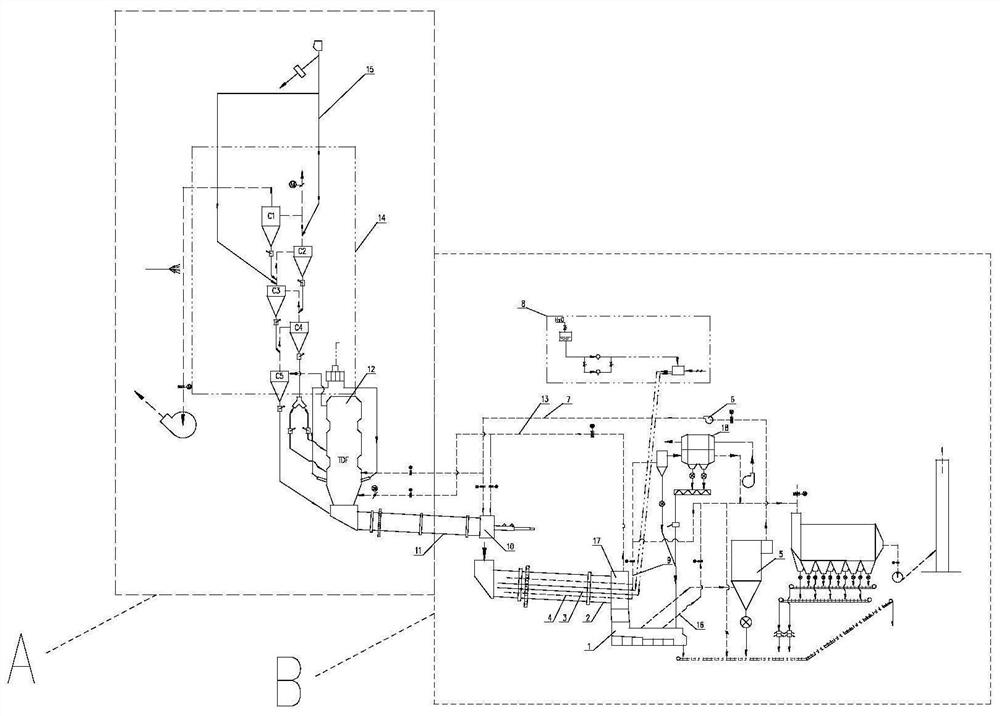

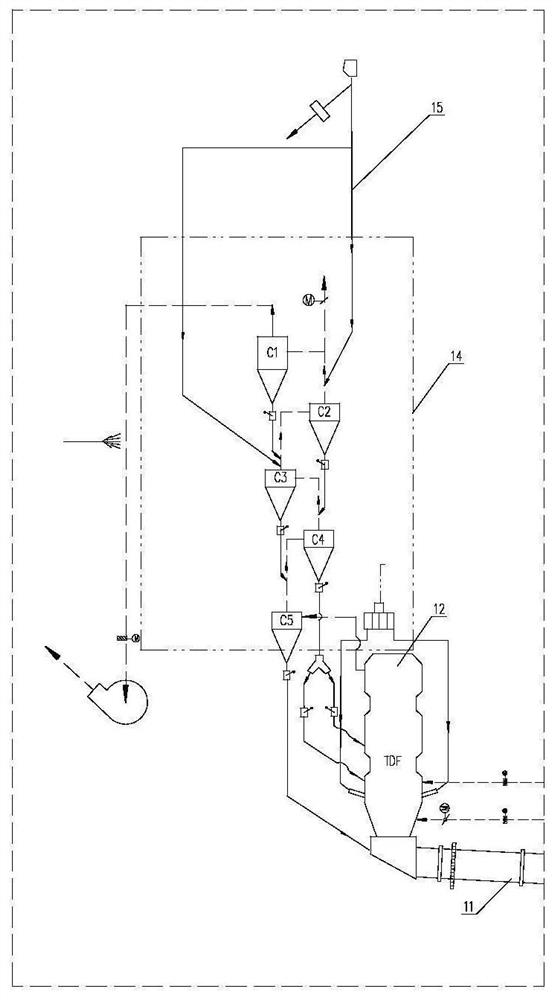

Mechanical grate type waste gasifying incinerator and boiler power generation system thereof

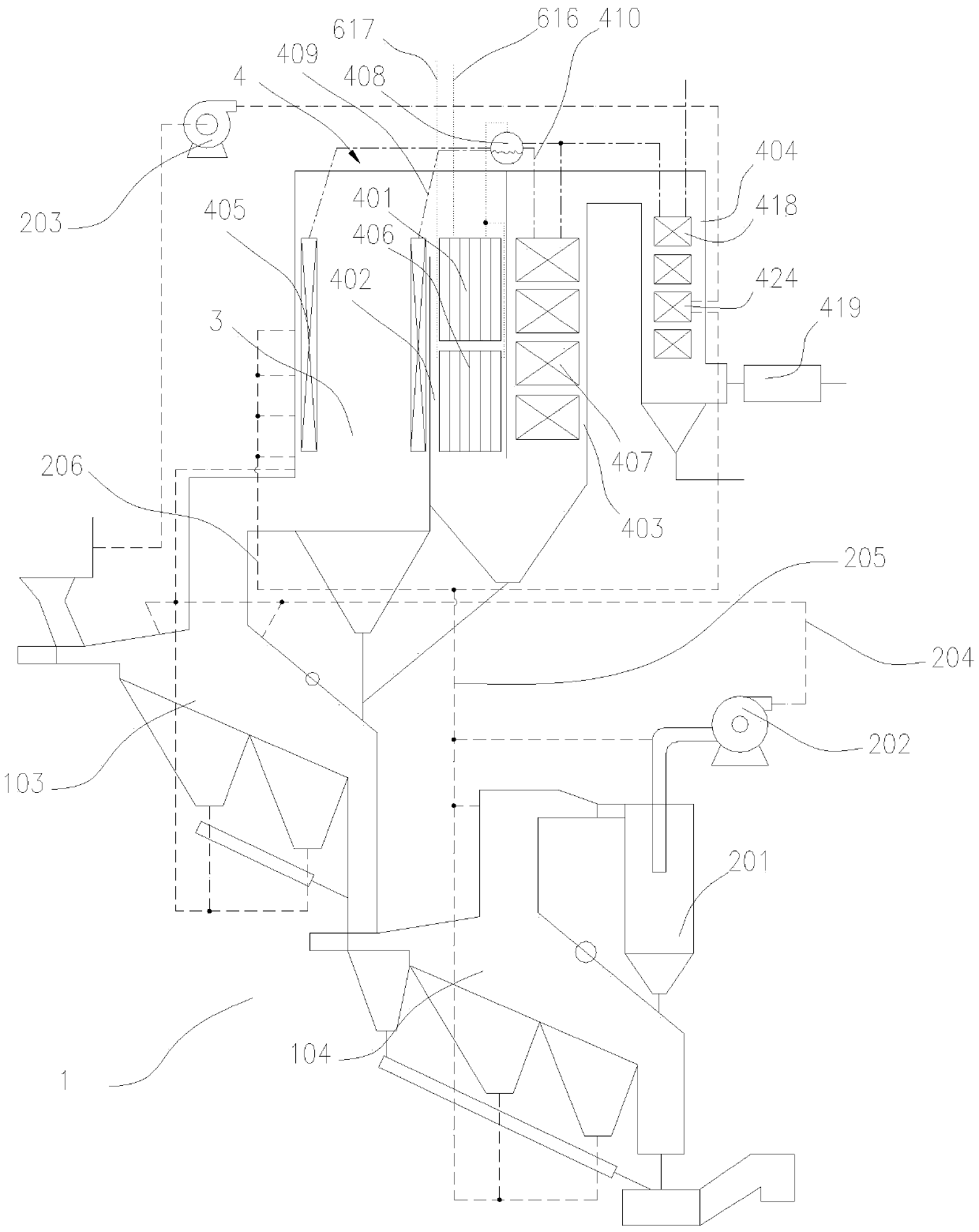

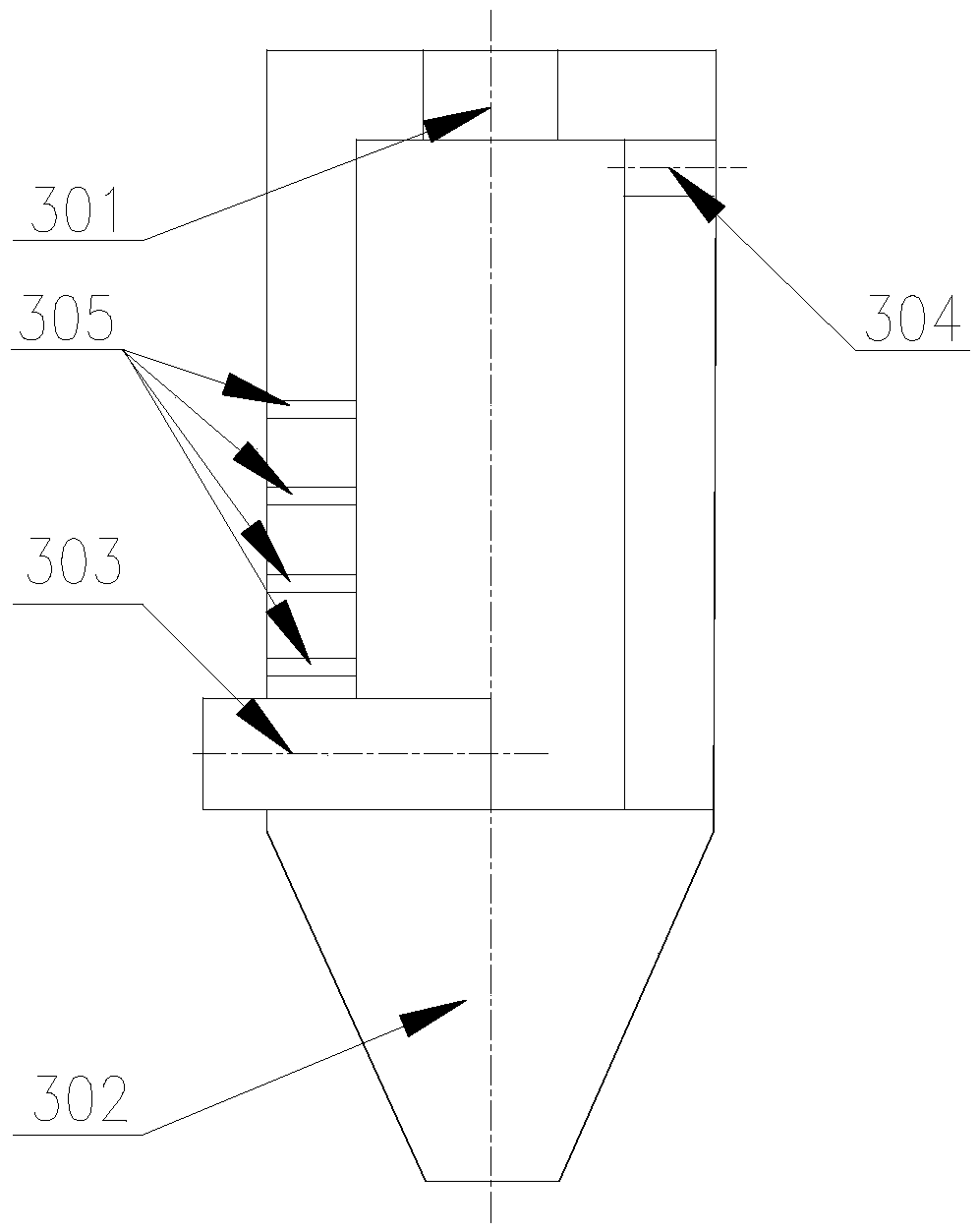

ActiveCN105509060AImprove qualityEasy to remove dustSteam engine plantsIncinerator apparatusCombustion chamberEngineering

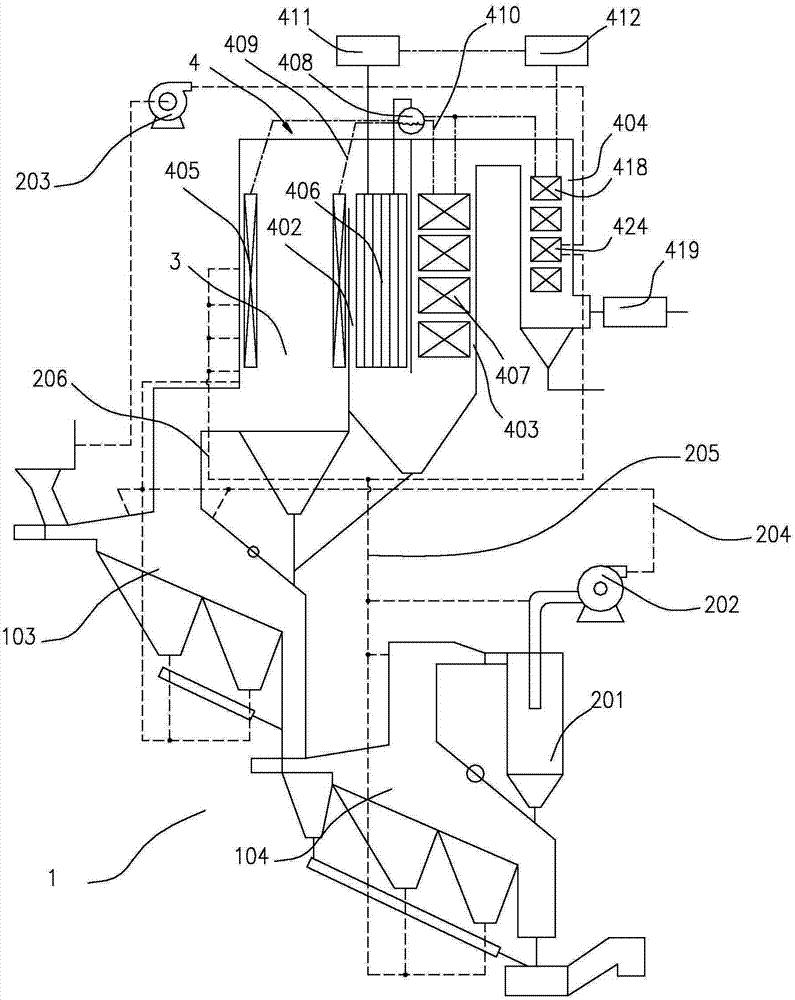

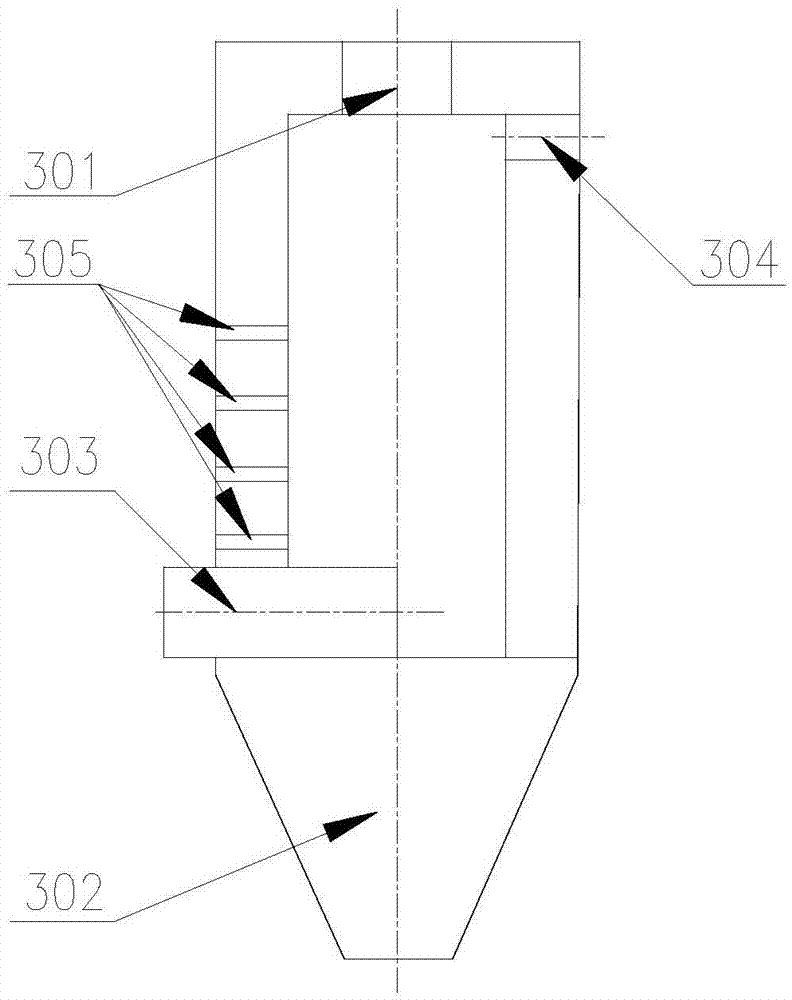

The invention discloses a mechanical grate type waste gasifying incinerator which is smaller in heat conversion efficiency loss and is higher heat recovery efficiency, and a boiler power generation system thereof. The mechanical grate type waste gasifying incinerator comprises a gasifying incinerator, a boiler system, an air supply system and a power generation system, wherein the gasifying incinerator comprises a gasifier and an incinerator, the gasifier and the incinerator can be sealed or communicated, and an upper end of the gasifier and the incinerator are respectively provided with a smoke outlet; the boiler system comprises a boiler body, the boiler body is provided with a cyclone combustion chamber, a furnace chamber a and a furnace chamber b which are communicated with one another, a water-cooled wall is arranged in the cyclone combustion chamber, superheaters are arranged in the furnace chamber a, an evaporator is arranged in the furnace chamber b, and a top end of the boiler body is provided with a steam drum; the power generation system comprises a steam turbine, a power generator and a steam input pipe, an output end of the steam turbine is sequentially connected with a condenser, a water pump, a low-pressure steam water heater, a deaerator, a booster pump and a high-pressure steam water heater, and first-stage and second-stage water-steam separators and first-stage and second-stage high-pressure steam-steam heaters are arranged between air cylinders of the steam turbine.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

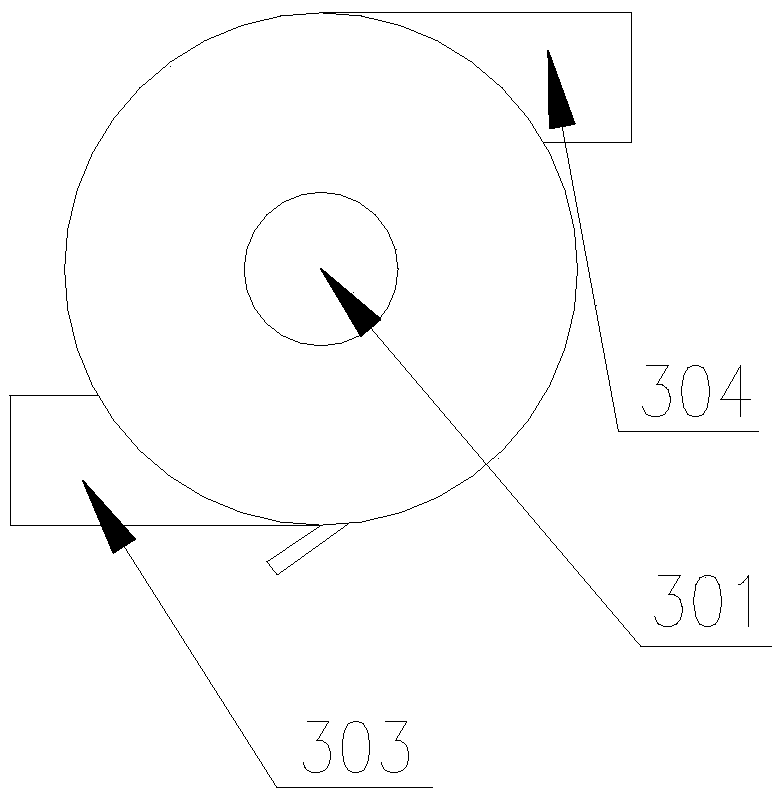

Hot-melt-type solidification latent heat pump capable of recycling waste heat

InactiveCN104654573ARealization of solidification heat utilizationImprove heating efficiencyFluid heatersCorrosion preventionEvaporationEngineering

The invention provides a hot-melt-type solidification latent heat pump capable of recycling waste heat and belongs to the field of heat pumps. The heat pump comprises a compressor, a condensate water box dry filter, a throttling device, an evaporation water tank, a gas-liquid separator, an evaporation water tank circulating pump, a condensate water box circulating pump, a liquid level meter, a user heat utilization system, a water collector, a dirt separation, a tap water electromagnetic valve, a drainage electromagnetic valve and a controller. Compared with a conventional sewage source heat pump system, the heat pump provided by the invention has the advantages that deep living sewage utilization is realized; through melting and removing ice by virtue of waste heat of living sewage, two alternate freezing and ice melting processes on a heat exchange surface are reduced, the living sewage temperature is reduced, the perennial normal starting and stable operation of a heat pump unit is ensured, furthermore, heat provided by a low-order heat source can meet the consumed heat load demand of a user, the structure is simple, maintenance and overhaul are convenient, and the heat pump can be widely applied to the fields of domestic hot-water supply and heat supply.

Owner:DALIAN UNIV OF TECH

Mechanical grate-type garbage single-furnace gasifying incineration and boiler system

The invention discloses a mechanical grate-type garbage single-furnace gasifying incineration and boiler system which is smaller in transformation heat efficiency loss and higher in heat recovery rate. The system comprises a gasifying incineration furnace, a boiler system and an air supply system, wherein the gasifying incineration furnace comprises a material feeding cabin and a furnace body; a material stacking sealing section is arranged between the material feeding cabin and the furnace body; the upper end of the furnace body is upwards convex and is provided with a first smoke outlet; the boiler system comprises a boiler body; the boiler body comprises a cyclone combustor, a furnace chamber a and a furnace chamber b which are communicated with one another; a water-cooling wall is arranged in the cyclone combustor; a superheater is arranged in the furnace chamber a; an evaporator is arranged in the furnace chamber b; the smoke inlet of the cyclone combustor is connected with the first smoke outlet; the top end of the boiler body is provided with a steam pocket; a steam-water inlet is formed in the steam pocket; the steam pocket is connected with water-cooling wall and the water inlet of the evaporator for outputting water; the water-cooling wall and the steam outlet of the evaporator are connected with the steam inlet of the steam pocket for steam backflow; and the saturated steam outlet of the steam pocket is used for outputting superheated steam through the superheater.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

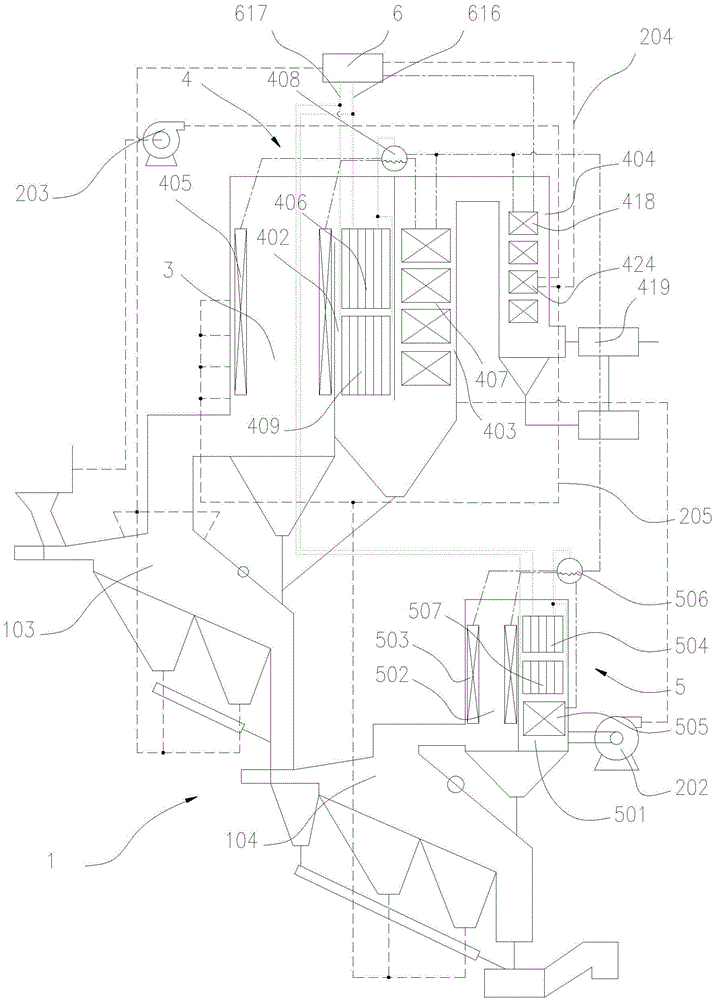

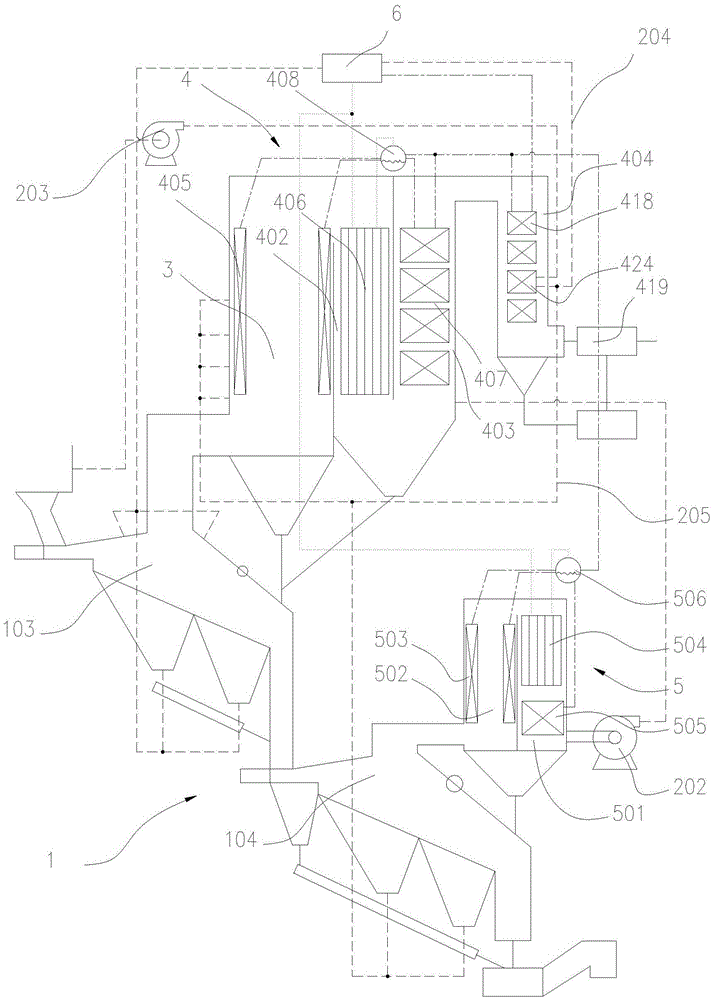

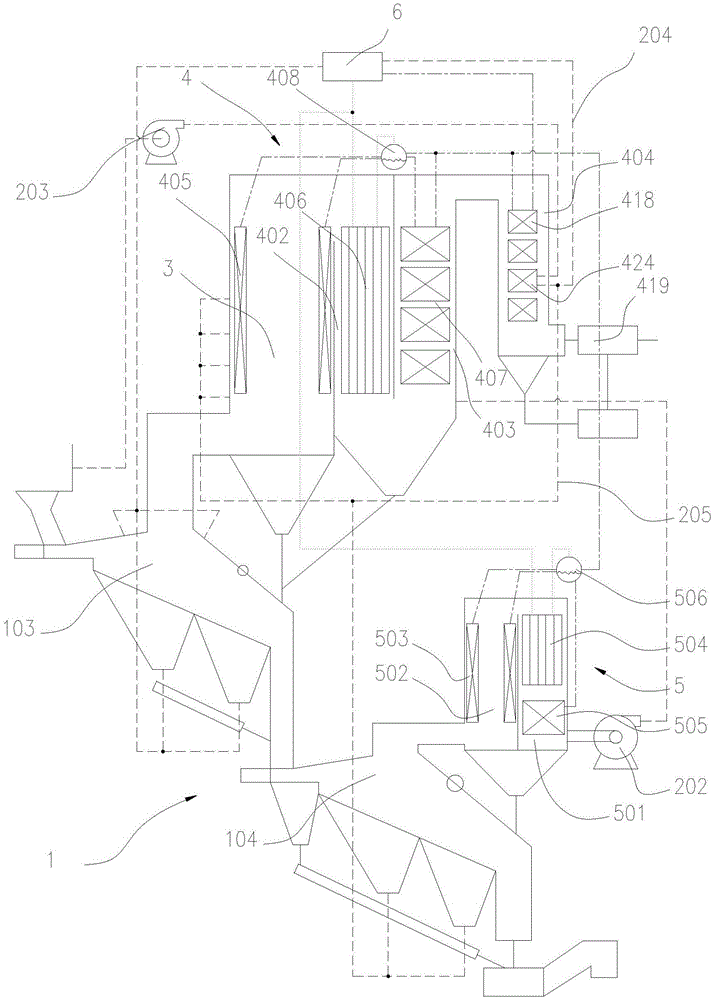

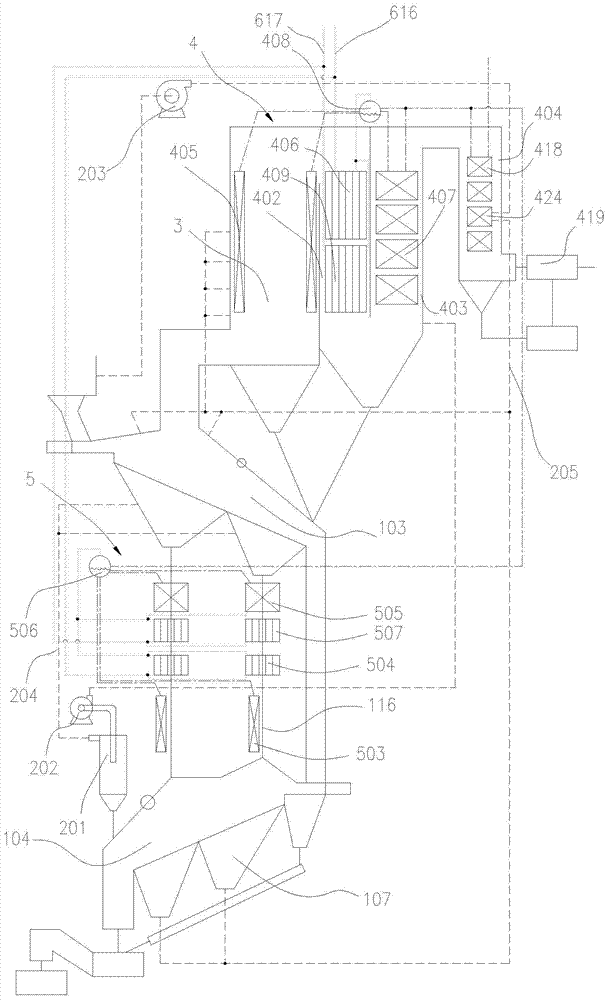

Mechanical fire grate type rubbish gasification incinerator and dual-boiler energy-saving power generation system thereof

ActiveCN105588131AImprove qualityEasy to remove dustMachines/enginesSteam generation plantsCycloneCombustion chamber

The invention discloses a mechanical fire grate type rubbish gasification incinerator which is smaller in heat efficiency conversion loss and higher in heat recovery rate and a dual-boiler energy-saving power generation system of the mechanical fire grate type rubbish gasification incinerator. The mechanical fire grate type rubbish gasification incinerator comprises a gasification incinerator body, a boiler system, a circulation air supply system and a power generation system; the gasification incinerator body comprises a gasification boiler and a burning ash boiler which can be sealed or communicated; the boiler system comprises boiler bodies a and b, the boiler body a is provided with a cyclone burning chamber and boiler chambers a and b, the boiler body b is provided with a boiler chamber d and a cyclone dust removal chamber, water cooling walls are arranged in the cyclone burning chamber and the cyclone dust removal chamber, a superheater unit is arranged in the boiler chamber a, and an evaporator is arranged in the boiler chamber b; and a superheater unit and an evaporator are arranged in the boiler chamber d, steam pockets are arranged at the top ends of the two boiler bodies, a smoke inlet of the cyclone burning chamber is connected with a smoke outlet of the gasification incinerator body, and a smoke inlet of the cyclone dust removal chamber is connected with a smoke outlet of the burning ash boiler. The power generation system comprises a steam input pipe, a steam turbine and a power generator, and the steam input pipe is connected with the superheater units a and b and the steam turbine.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

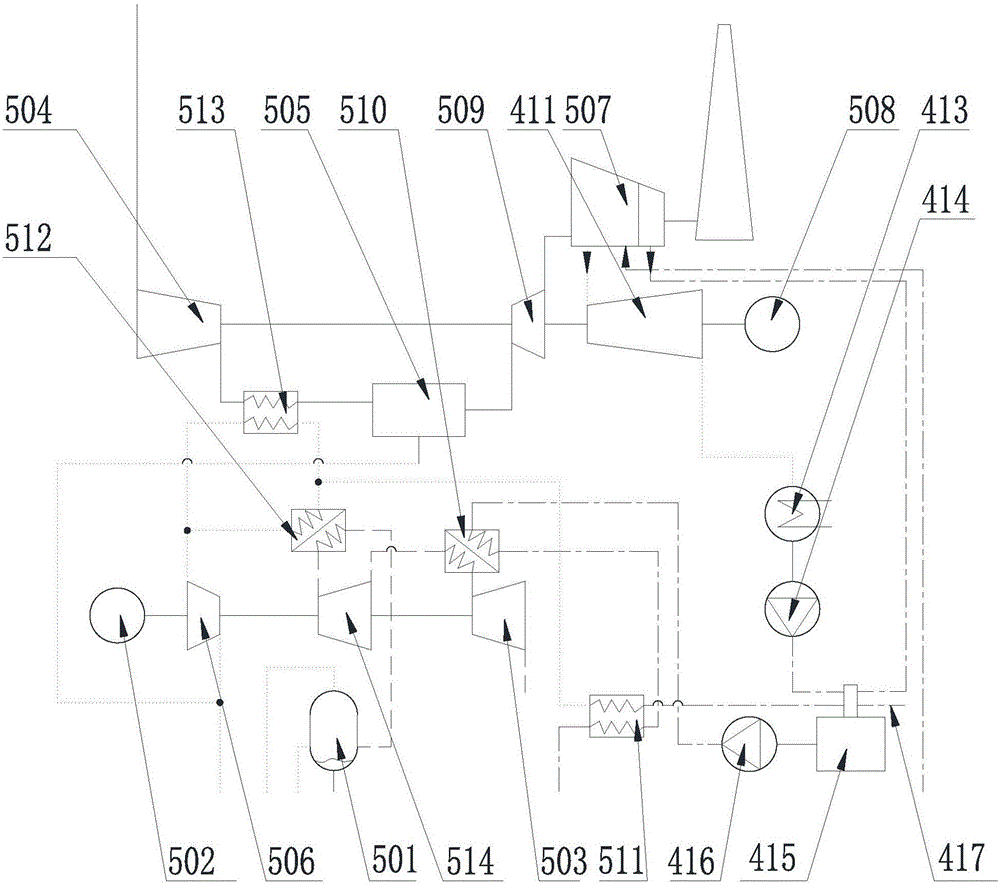

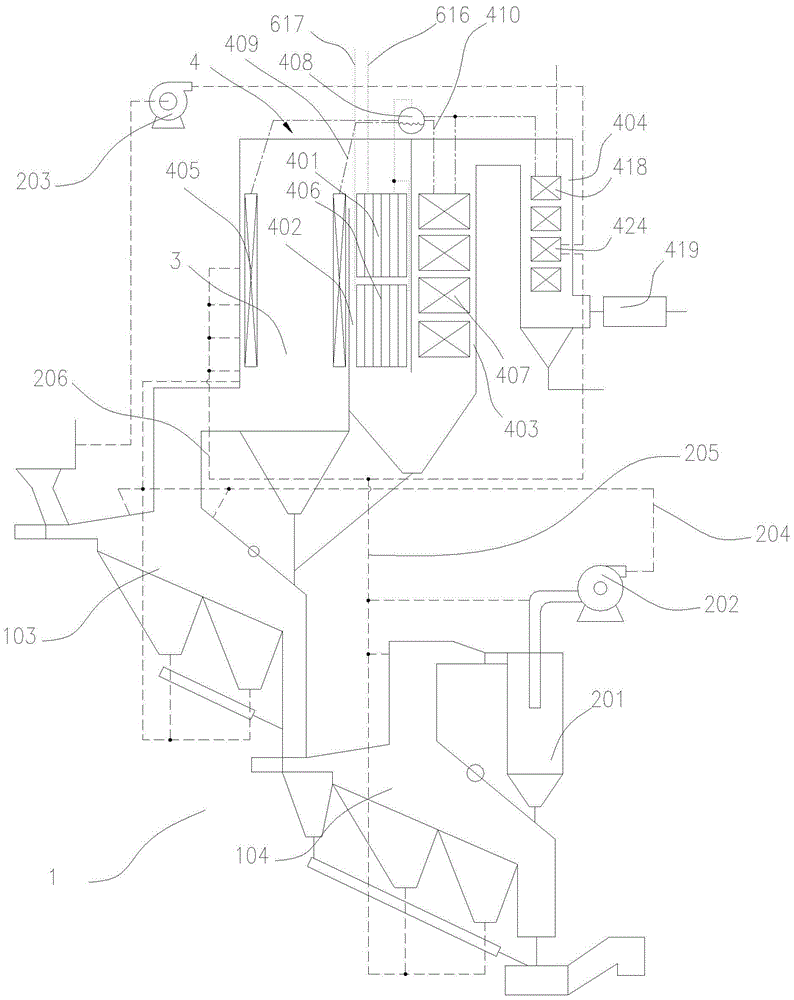

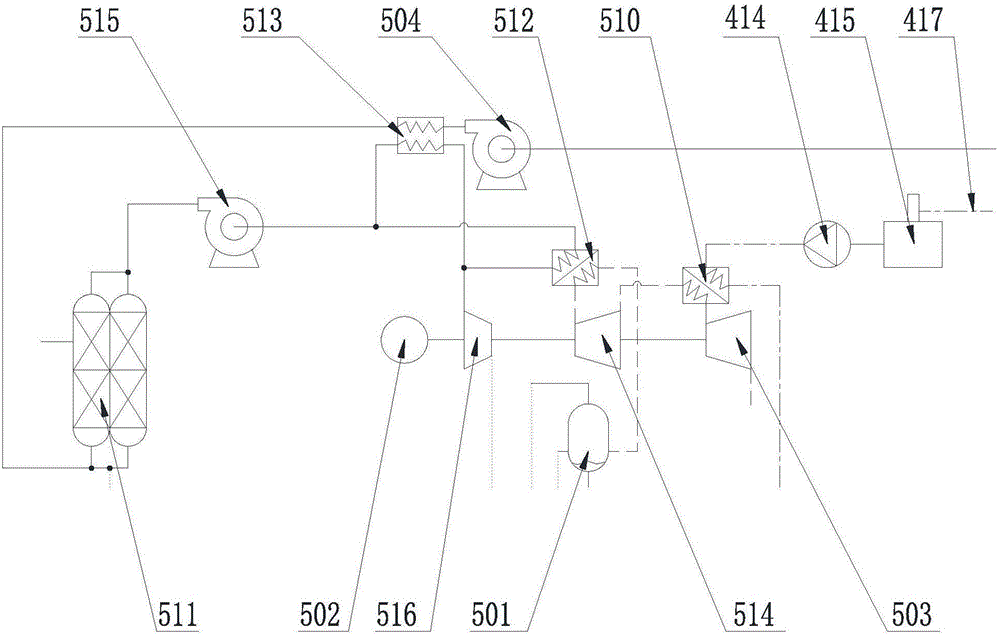

Gas turbine-steam turbine coaxial combined power generation system based on waste gasification

ActiveCN106287642AImprove qualityEasy to remove dustSteam generation plantsSteam engine plantsCombustion chamberGas compressor

The invention discloses a gas turbine-steam turbine coaxial combined power generation system based on waste gasification. The gas turbine-steam turbine coaxial combined power generation system comprises a waste gasification incineration system, a boiler system and a power generation system, wherein the power generation system comprises a mixer, an air compressor, a synthetic flue gas compressor, a synthetic flue gas combustion chamber, a turbine, a steam turbine, a power generator, a waste heat boiler and a water supply input system; the inlet of the mixer is connected with the saturated steam outlet of a steam manifold and the air outlet of the air compressor; the water outlet of the mixer is connected with the water inlet of the steam manifold; the steam outlet of the mixer is connected with the steam inlet of a super-heater; the gas inlet of the flue gas compressor is connected with the waste gas discharge outlet of the boiler system; the steam outlet of the super-heater and the gas outlet of the flue gas compressor are connected with the synthetic flue gas combustion chamber, the turbine and the waste heat boiler in sequence; the steam outlet of the waste heat boiler is connected with the steam inlet of the steam turbine; the turbine, the steam turbine and the power generator are in power connections. By adopting the gas turbine-steam turbine coaxial combined power generation system, large-scale continuous waste gasification treatment can be performed, high heat recovery efficiency is achieved, and pollutant discharge is reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Boiler power generation system utilizing rubbish gasification and incineration synthesis gas

ActiveCN105464727AIncrease profitLarge amount of garbage disposalLiquid degasificationSteam engine plantsSyngasEngineering

The invention discloses a boiler power generation system utilizing rubbish gasification and incineration synthesis gas. The boiler power generation system is small in heat conversion efficiency loss and higher in heat recovery efficiency. The boiler power generation system comprises a steam turbine, a generator, a high-pressure steam input pipe and a medium-pressure steam input pipe. The steam turbine comprises a high-pressure steam cylinder, a medium-pressure steam cylinder and a low-pressure steam cylinder. A first-stage water-steam separator and a first-stage high-pressure steam-steam heater are connected between the high-pressure steam cylinder and the medium-pressure steam cylinder. A second-stage water-steam separator and a second-stage high-pressure steam-steam heater are connected between the medium-pressure steam cylinder and the low-pressure steam cylinder. The steam output end of the low-pressure steam cylinder is connected with a condenser, a water pump, a low-pressure steam-water heater, a deaerator, a booster water pump and a high-pressure steam-water heater in sequence through a pipeline. The high-pressure steam input pipe is connected with the high-pressure steam cylinder and is connected with the deaerator through the heating end of the first-stage high-pressure steam-steam heater, the heating end of the high-pressure steam-water heater, the heating end of the second-stage high-pressure steam-steam heater and the heating end of the low-pressure steam-water heater.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

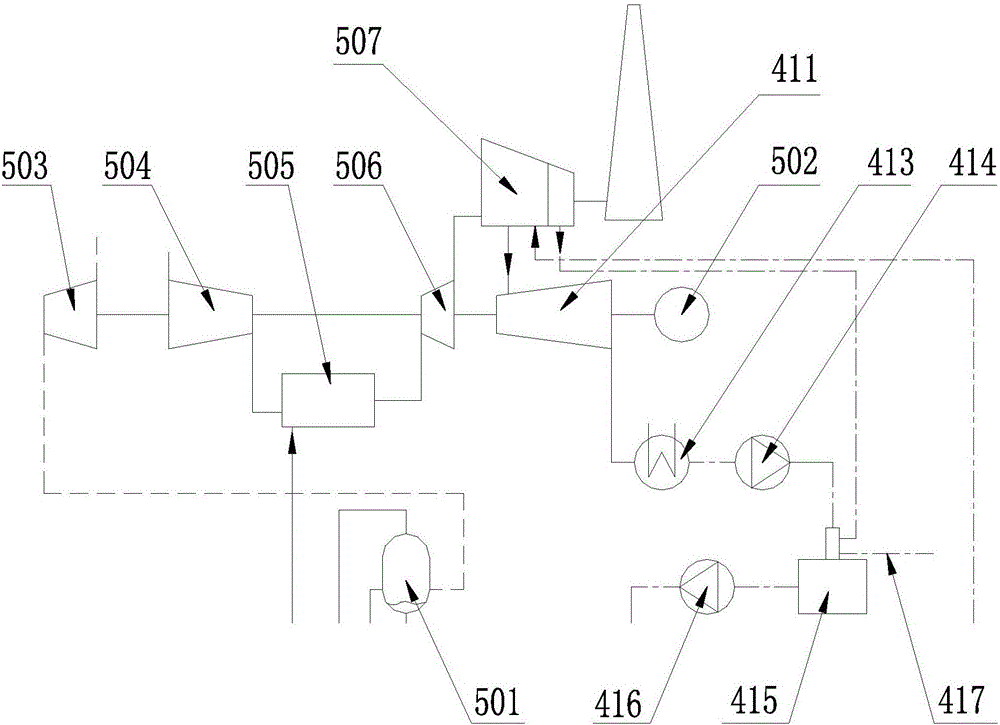

Wet air turbine power generation system based on recycling of garbage gasifying synthesis gas

ActiveCN106224035AImprove recycling efficiencyPyrolysis is beneficialChemical industrySteam useProcess engineeringAir compressor

The invention discloses a wet air turbine power generation system based on recycling of garbage gasifying synthesis gas. The wet air turbine power generation system based on recycling of the garbage gasifying synthesis gas comprises a garbage gasifying system, a boiler system and a power generation system, wherein the power generation system comprises a mixer, a low-pressure air compressor, a high-pressure air compressor, a turbine, a generator, an air steam-gas heat exchanger, a CO2 steam-gas heat exchanger, a CO2 fan, a recycling fan, a mixing separator, a CO2 separator and a water supply feeding system of the boiler system; the CO2 separator is connected to space between a waste gas discharge opening of the boiler system and a gas inlet of the CO2 fan; and a gas outlet of the turbine is in parallel connection with heating channels of the CO2 steam-gas heat exchanger and the air steam-gas heat exchanger, and is then connected with the recycling fan and the mixing separator. By the wet air turbine power generation system based on recycling of garbage gasifying synthesis gas, a large amount of garbage is continuously gasified and incinerated, the treatment amount of the garbage is high, recycling efficiency of heat is high, regenerated chemical raw materials and synthesized natural gas can be extracted, and near zero emission of pollutants and CO2 can be realized effectively.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate type garbage gasification and incineration furnace and double-boiler power generation system

ActiveCN105627320AImprove qualityEasy to remove dustSteam engine plantsIncinerator apparatusCycloneCombustion chamber

The invention discloses a mechanical grate type garbage gasification and incineration furnace and double-boiler power generation system with relatively small heat conversion efficiency loss and higher heat recovery efficiency. The system comprises a gasification and incineration furnace, a boiler system, a circulating air supply system and a power generation system, wherein the gasification and incineration furnace comprises a gasifier and an incinerator, which can be sealed or communicated; the boiler system comprises boiler bodies a and b; the boiler body a comprises a cyclone combustion chamber and furnace chambers a and b; the boiler body b comprises a furnace chamber d and a cyclone dust chamber; water cooling walls are arranged in the cyclone combustion chamber and the cyclone dust chamber; a superheater is arranged in the furnace chamber a; an evaporator is arranged in the furnace chamber b; a superheater and an evaporator are arranged in the furnace chamber d; steam pockets are arranged at the top ends of the two boiler bodies; a smoke inlet of the cyclone combustion chamber is connected with a smoke outlet of the gasifier; a smoke inlet of the cyclone dust chamber is connected with a smoke outlet of the incinerator; the power generation system comprises a steam inlet pipe, a steam turbine and a power generator; and the steam inlet pipe is connected with the superheaters a and b and the steam turbine.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate type waste gasification incinerator and boiler system thereof

ActiveCN105423307AImprove qualityEasy to remove dustSteam superheatersIncinerator apparatusCombustion chamberSlag

The invention discloses a mechanical grate type waste gasification incinerator with less conversion thermal efficiency loss and higher thermal recovery efficiency and a boiler system of the waste gasification incinerator. The mechanical grate type waste gasification incinerator comprises a gasification incinerator, the boiler system and a circulating air supply system, wherein the gasification incinerator comprises a feeding bin, a gasifier and a burnout furnace, a stockpiling sealing section is arranged between the feeding bin and the gasifier, a transition slag blanking section is arranged between the gasifier and the burnout furnace, and flue gas outlets are formed in the upper ends of the gasifier and the burnout furnace respectively. The boiler system comprises a boiler body, the boiler body is provided with a cyclone combustion chamber, a furnace chamber a and a furnace chamber b which are mutually communicated, a water cooling wall is arranged in the cyclone combustion chamber, a superheater is arranged in the furnace chamber a, an evaporator is arranged in the furnace chamber b, a steam drum is arranged at the top end of the boiler body, a steam-water inlet is formed in the steam drum, the steam drum is connected with water inlets of the water cooling wall and the evaporator and used for outputting water, steam outlets of the water cooling wall and the evaporator are connected with a steam inlet of the steam drum for backflow of steam, and a saturated steam outlet of the steam drum outputs superheated steam through the superheater.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Method for manufacturing electric heating plate

ActiveCN101664278BWon't burnWon't breakSurface layering apparatusSold ingredients supply apparatusElectricityElectrical resistance and conductance

The invention discloses a method for manufacturing an electric heating plate, comprising the following processing steps: (1) evenly mixing high-alumina cement, high-alumina fireclay, high-alumina aggregate and quartz sand, and then adding an amount of water to enable the mixture to be pasty; (2) adopting a pressure machine to press the mixture into a heating plate; (3) evenly mixing high-alumina fireclay and quartz sand, and then adding an amount of water to enable the mixture to be pasty; (4) adding an amount of materials obtained in the step 3 after a heating filament is added to the heating plate, enabling the heating filament to be completely covered; (5) evenly mixing high-alumina cement, temperature-resistance clay and river sand, and then adding an amount of water to enable the mixture to be pasty; (6) enabling the materials obtained in the step 5 to be covered on the surface of the heating plate so as to enable the surface of the heating plate to be smooth; (7) and naturally drying the heating plate until the heating plate is solidified. The electric heating plate manufactured by the process can collect and store heat generated by resistance wires, and therefore, the goal of heat reutilization is effectively achieved, and the process can be widely applied to manufacturing the electric heating plates of heating equipment of electric cookers, electric food warmers and the like.

Owner:魏学东

Double-boiler power generating system capable of incinerating syngas through garbage gasification

ActiveCN105627324AGuaranteed qualityReduce lossSteam generation plantsIndirect carbon-dioxide mitigationSyngasDeaerator

The invention discloses a double-boiler power generating system capable of incinerating syngas through garbage gasification, and the double-boiler power generating system is small in heat conversion efficiency loss and higher in heat recovery efficiency. The double-boiler power generating system comprises a steam input pipe, a steam turbine and a power generator. The steam input pipe is connected with the steam input end of the steam turbine. The steam output end of the steam turbine is sequentially connected with a condenser, a water pump, a low-pressure steam water heater, a deaerator, a booster water pump and a high-pressure steam water heater. The heated input end of the low-pressure steam water heater is connected with the water pump, and the heated output end of the low-pressure steam water heater is connected with the deaerator. The heated input end of the high-pressure steam water heater is connected with the booster water pump, and the heated output end of the high-pressure steam water heater is used for outputting water which is used for boilers. The steam turbine is provided with a first steam fetching pipe and a second steam fetching pipe which are used for fetching steam from the steam output end of the steam turbine. The output end of the first steam fetching pipe is connected with the heating input end of the high-pressure steam water heater. The output end of the second steam fetching pipe is connected with the heating input end of the low-pressure steam water heater.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Drying room afterheat recycling device

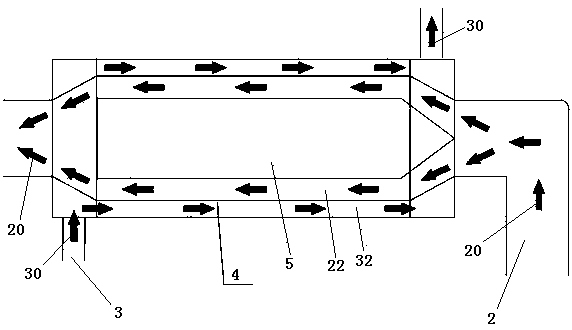

InactiveCN105371643AAchieve recyclingReduce the temperatureDrying solid materialsStationary tubular conduit assembliesFresh airEnergy conservation

The invention discloses a drying room afterheat recycling device. The device comprises a heat exchanging body, wherein the heat exchanging body comprises a shell, a fresh air passage and a hot waste air passage which are arranged inside the shell; a heat exchanging device is arranged between the fresh air passage and a hot waste air passage; the heat of waste air which flows through the hot waste air passage can be absorbed by utilizing a heat exchange theory. By utilizing a circulating heat conduction and exchange theory, the drying room afterheat recycling device disclosed by the invention is capable of realizing recycle of waste heat, energy-saving and environment-friendly; the drying room afterheat recycling device disclosed by the invention is of a square box type structure and is simple in structure, convenient to wash and maintain and small in floor space by being placed above a drying room; the temperature of a pipeline wall can be reduced by the waste air after the waste air passes through the afterheat recycling device; heat radiation caused by the temperature of a waste air exhausting system to the air can be reduced; the comprehensive energy conservation is about 20%.

Owner:JIANGSU HAIDA DYEING & PRINTING MACHINERY

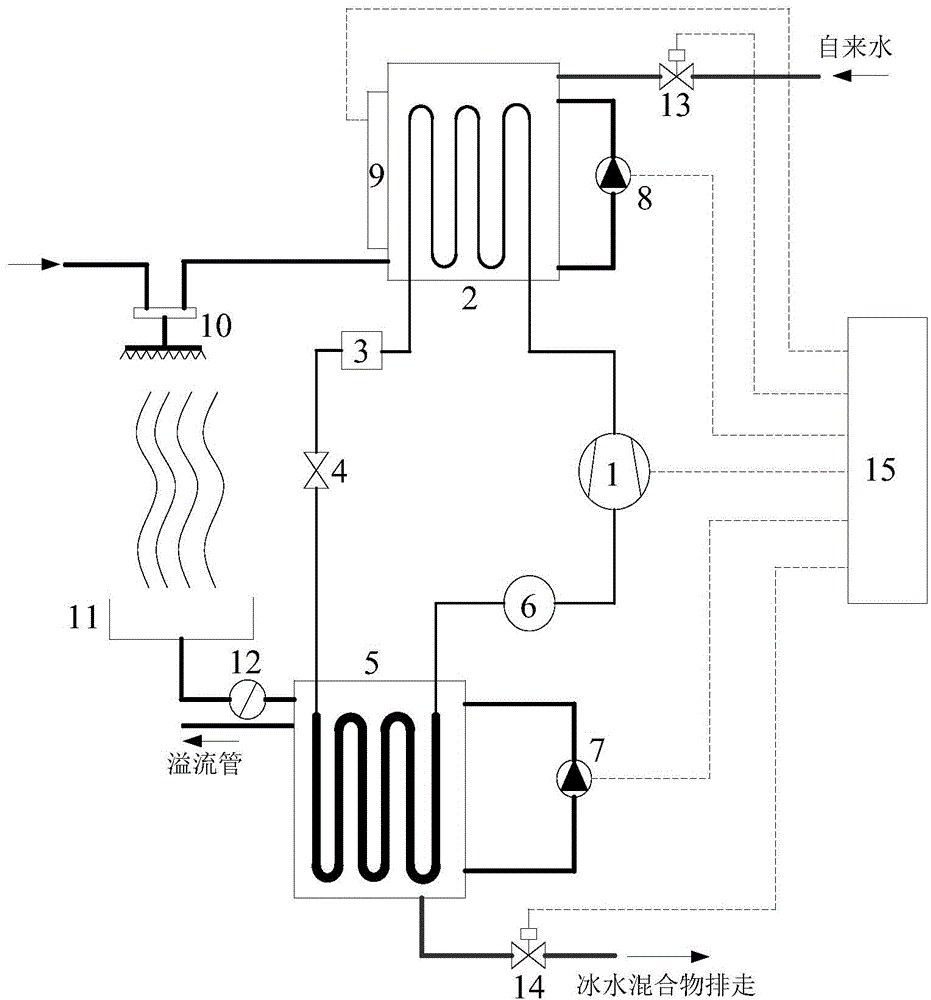

Heat energy reutilization process of freezing filter unit

InactiveCN108827053AScientific and reasonable structureRealize heat recovery and utilizationRecuperative heat exchangersProcess engineeringHeating energy

The invention provides a heat energy reutilization process of a freezing filter unit. According to the heat energy reutilization process of the freezing filter unit, heat energy generated by a refrigeration system is brought into a heat energy exchanger through cooling water for exchange and recovery with required heat energy liquid, and then the cooling water enters a cooling tower for circulation with the refrigeration system and the heat exchanger through a cooling pump. The heat energy reutilization process of the freezing filter unit is scientific and reasonable in process, simplicity, practicality and high-efficiency are achieved, and recovery and utilization of heat energy are realized.

Owner:高云芝

Device and method for disposing multiple kinds of waste synergistically in cement kiln

PendingCN110566971ABurn fullyBurn quicklyIncinerator apparatusWaste heat treatmentCombustionFlue gas

The invention discloses a device and method for disposing multiple kinds of waste synergistically in a cement kiln. The device for disposing the multiple kinds of waste synergistically in the cement kiln comprises a furnace body. A feeding port and an air inlet are formed in the top of the furnace body. A slag discharging port is formed in the bottom of the furnace body. A feeding wind-locking machine is arranged in the position of the feeding port. A wind-locking valve set is arranged at the slag discharging port. A number of spraying nozzles and a number of incineration platforms in a horizontal state are arranged in the furnace body. The incineration platforms are distributed in staggered layers in the furnace body. Each incineration platform is provided with a sweeping mechanism and aflow-aiding mechanism. The cleaning mechanisms are used for pushing waste on the incineration platforms to be out and fall to next-layer incineration platforms. The flow-aiding mechanisms are used forscattering waste on the incineration platforms. The device further comprises a cement kiln decomposition furnace. A flue gas discharging port is formed in the lower portion of the furnace body. The flue gas discharging port communicates with a flue gas receiving port of the cement kiln decomposition furnace. The tertiary air outlet of the cement kiln decomposition kiln communicates with the air inlet of the furnace body. By means of the device for disposing the multiple kinds of waste synergistically in the cement kiln, combustion sufficiency and efficiency of the waste can be improved, and meanwhile, the cement quality is not influenced.

Owner:成都铭炬环保工程技术有限公司

Double-layer mechanical grate type garbage gasification incinerator and its boiler power generation system

ActiveCN105465789BImprove insulation effectPrevent leakageSteam engine plantsIncinerator apparatusCombustion chamberFlue gas

The invention discloses a double-layer mechanical grate type garbage gasification incinerator and its boiler power generation system, including a double-layer garbage gasification incinerator, a boiler system, a circulating air supply system, a power generation system, and a double-layer garbage gasification incinerator The ember furnace is located directly below the gasification furnace, and the gasification furnace and the upper end of the ember furnace are provided with flue gas outlets. The boiler system includes a boiler body, and the boiler body has a cyclone combustion chamber, furnace chamber a, furnace chamber b, and cyclone A water-cooled wall is set in the combustion chamber, a superheater is set in the furnace room a, an evaporator is set in the furnace room b, a steam drum is set on the top of the boiler body, and the superheater outputs superheated steam; the power generation system includes a steam turbine, a generator, a steam input pipe, and a steam turbine The output end is sequentially connected to the condenser, water pump, low-pressure steam-water heater, deaerator, booster water pump, and high-pressure steam-water heater. The first and second-stage water-steam separators and the first and second-stage high-pressure Steam heater.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

A powder spraying process and equipment for heat preservation cover

ActiveCN109926250BDry fastRealize the function of one water and two usesHollow article cleaningPretreated surfacesThermal insulationEngineering

The invention provides a powder spraying process and equipment for a thermal insulation cover, belonging to the technical field of processing. The powder spraying equipment of this thermal insulation cover includes a cleaning machine, a powder spraying device and a curing device. The cleaning machine includes a body and a frame. The body is installed on the frame. The conveying mechanism, the powder spraying device includes a chassis, which is equipped with an upper conveying structure and a lower conveying structure, and the heat preservation cover passes through the upper conveying structure and the lower conveying structure in turn. There is at least one set of relative powder spraying mechanism 2, and the powder recovery device is connected to the chassis. The upper conveying structure is installed on the top of the chassis through the upper bracket, and the lower conveying structure is installed on the bottom of the chassis through the lower bracket. The curing device includes a curing box. , The curing box has a preheating chamber, a curing chamber and a cooling chamber. The invention enables the heat preservation cover to be sprayed with powder without dead angle in a clean state, and in addition, it is not easy to drop powder during curing.

Owner:浙江东蓝机电有限公司

Mechanical grate type garbage gasification incinerator and its boiler power generation system

ActiveCN105509060BImprove qualityEasy to remove dustSteam engine plantsIncinerator apparatusCycloneEmber

The invention discloses a mechanical grate type garbage gasification incinerator and a boiler power generation system thereof with less heat conversion efficiency loss and higher heat recovery efficiency. Including gasification incinerator, boiler system, air supply system, power generation system, gasification incinerator includes gasification furnace and ember furnace, the gasification furnace and ember furnace can be sealed or connected, the upper end of the gasification furnace, the ember furnace Furnaces are respectively equipped with flue gas outlets; the boiler system includes a boiler body, and the boiler body has a cyclone combustion chamber, furnace chamber a, and furnace chamber b that are connected to each other. An evaporator is installed, and a steam drum is installed on the top of the boiler body; the power generation system includes a steam turbine, a generator, and a steam input pipe. Heater, the first and second stage water vapor separators and the first and second stage high pressure steam heaters are arranged between the cylinders of the steam turbine.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Double-layer mechanical grate type waste gasification incineration double-boiler power generation system

ActiveCN105465793BImprove insulation effectPrevent leakageMachines/enginesIncinerator apparatusCycloneCombustion chamber

The invention discloses a double-layer mechanical grate type garbage gasification incineration double-boiler power generation system, which includes a double-layer garbage gasification incinerator, a boiler system, and a circulating air supply system. The double-layer garbage gasification incinerator includes a feed bin, The gasification furnace and the ember furnace, the ember furnace is located directly below the gasification furnace, the feeding direction of the ember furnace is opposite to that of the gasification furnace, and the upper end of the gasification furnace and the upper end of the ember furnace are provided with flue gas Outlet, the boiler system includes boiler body a, b, boiler body a has a cyclone combustion chamber, furnace chamber a, b, the flue gas inlet of the cyclone combustion chamber is connected to the flue gas outlet of the gasifier, and the boiler body b has a Evaporator b, superheater b, water wall b, superheater in furnace chamber a, evaporator in furnace chamber b, superheater and evaporator in furnace chamber d, and steam drums on the top of the two boiler bodies.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Equipment and process for switchable production of white cement clinker and Portland cement clinker

ActiveCN112125539AIncrease productionReduce energy consumptionRotary drum furnacesMaintainance of heating chambersProcess engineeringRotary kiln

The invention belongs to the field of cement firing processes and equipment, and particularly relates to equipment and a process for switchable production of white cement clinker and Portland cement clinker. Low-temperature secondary and tertiary air pipelines are adopted when the white cement clinker is produced, secondary and tertiary air is provided for fuel combustion of a rotary kiln and a decomposing furnace, and when the Portland cement clinker is produced, a high-temperature secondary air pipeline and a high-temperature tertiary air pipeline are switched to provide high-temperature secondary air and high-temperature tertiary air for fuel combustion of the rotary kiln and the decomposing furnace, or the high-temperature tertiary air pipeline is adopted to provide high-temperature tertiary air for fuel combustion of the decomposing furnace, secondary air enters the rotary kiln through a single-cylinder bleaching machine, and residual air is exhausted into a waste gas treatment system through a residual air pipeline. The equipment and the process for switchable production of the white cement clinker and the Portland cement clinker are provided to solve the problem that production processes of the white cement clinker and the Portland cement clinker cannot be switched and compatible, and manufacturers can flexibly select to produce the white cement clinker and the Portlandcement clinker by adopting the equipment and the process for switchable production of the white cement clinker and the Portland cement clinker according to market demands.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Double-layer mechanical grate type garbage gasification incinerator and its double-boiler system

ActiveCN105402738BImprove insulation effectPrevent leakageIncinerator apparatusCombined combustion mitigationCycloneCombustion chamber

The invention discloses a double-layer mechanical grate type garbage gasification incinerator and its double boiler system, comprising a double-layer garbage gasification incinerator, a boiler system, and a circulating air supply system. The double-layer garbage gasification incinerator includes a feed Bin, gasifier and ember furnace, the ember furnace is located directly below the gasifier, the feeding direction of the ember furnace is opposite to that of the gasifier, and the upper end of the gasifier and the upper end of the ember furnace are set The flue gas outlet, the boiler system includes the boiler body a, b, the boiler body a has a cyclone combustion chamber, the furnace chamber a, b, the flue gas inlet of the cyclone combustion chamber is connected to the flue gas outlet of the gasifier, and the boiler body b has a flue gas Evaporator b, superheater b, and water-cooled wall b on the pipeline, a superheater is installed in furnace chamber a, an evaporator is installed in furnace chamber b, a superheater and evaporator are installed in furnace chamber d, and steam drums are installed at the top of the two boiler bodies .

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

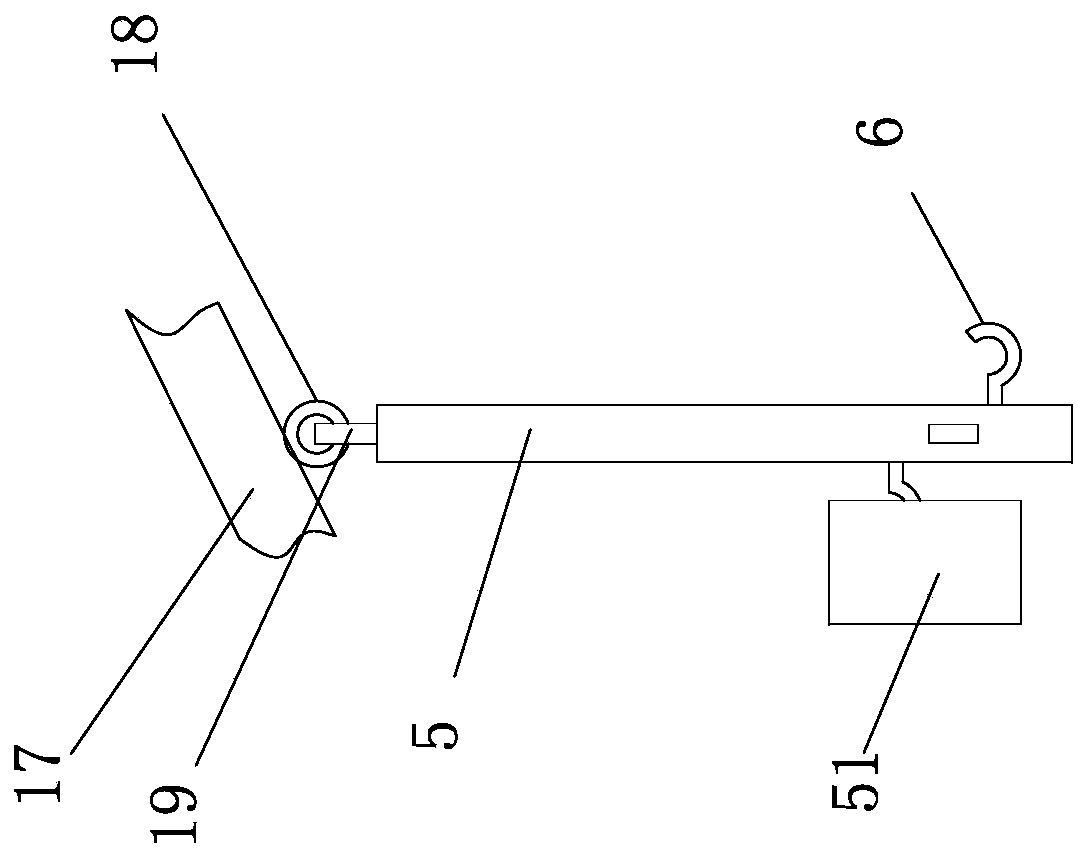

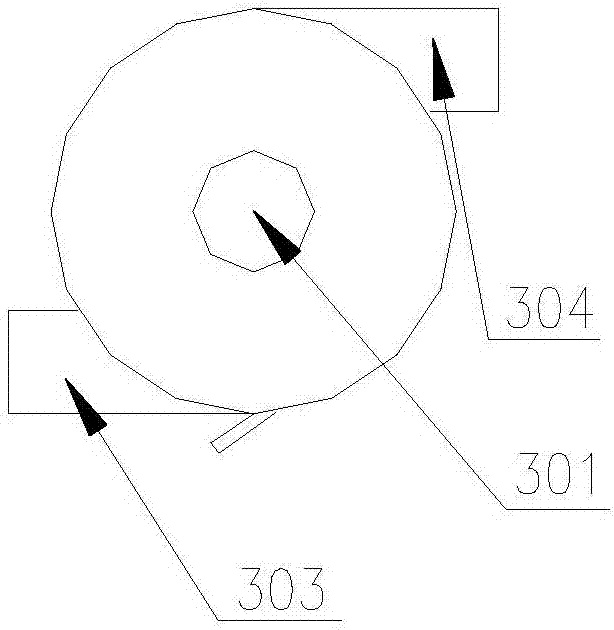

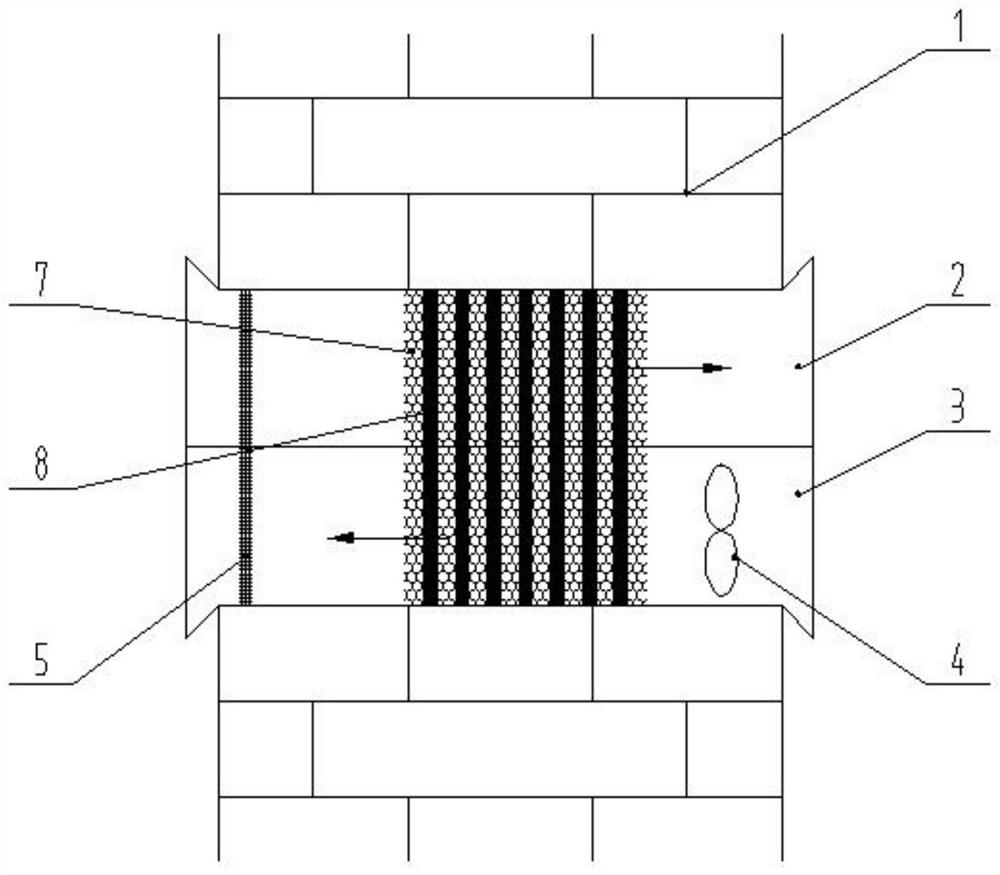

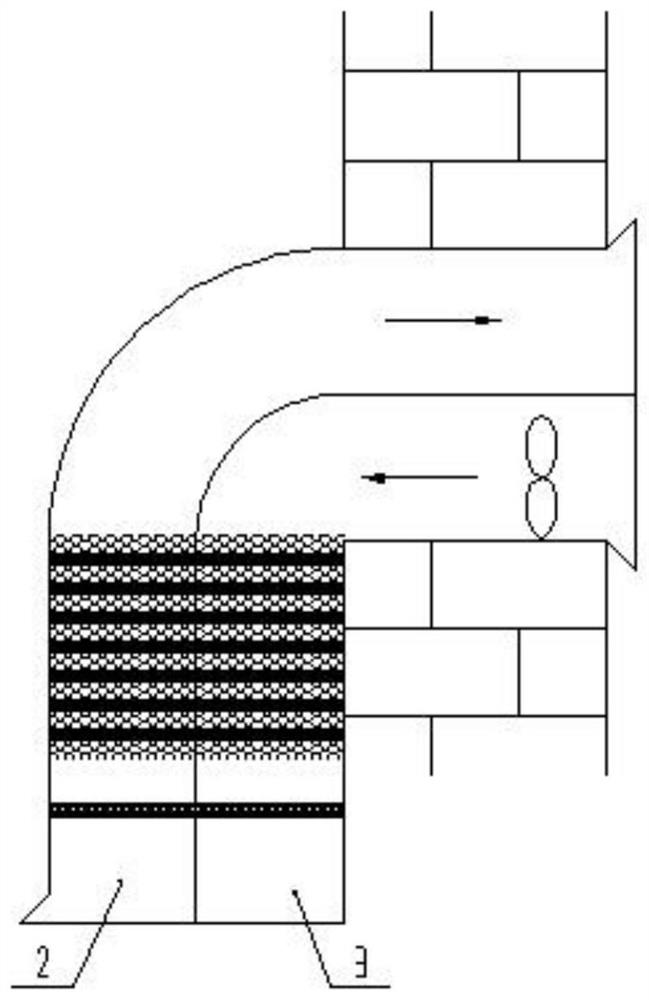

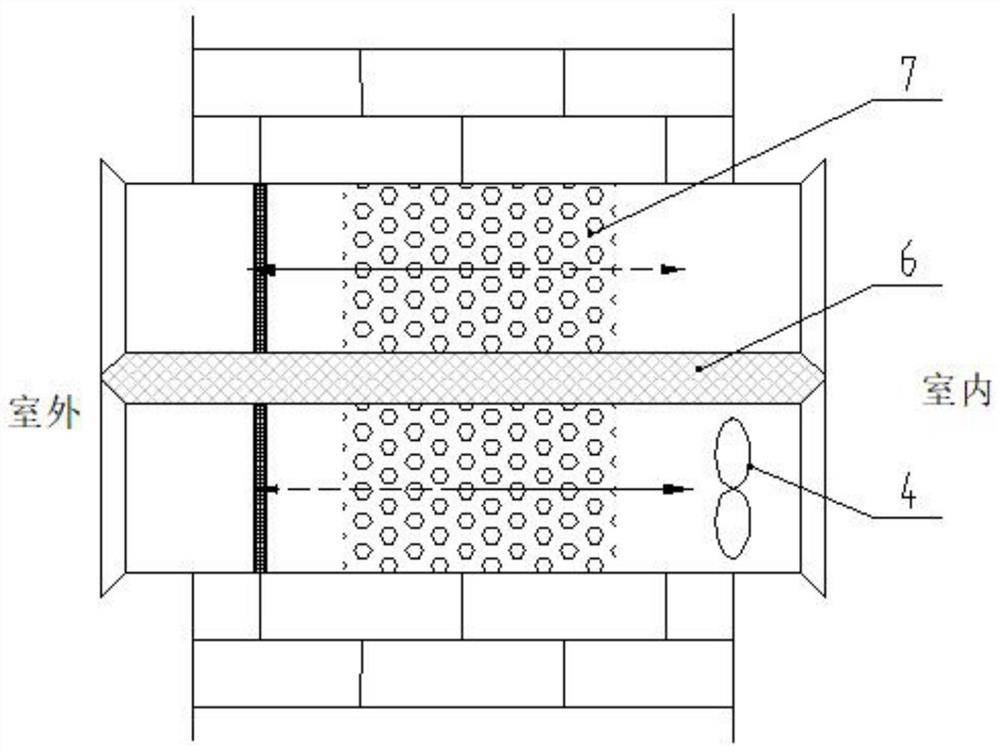

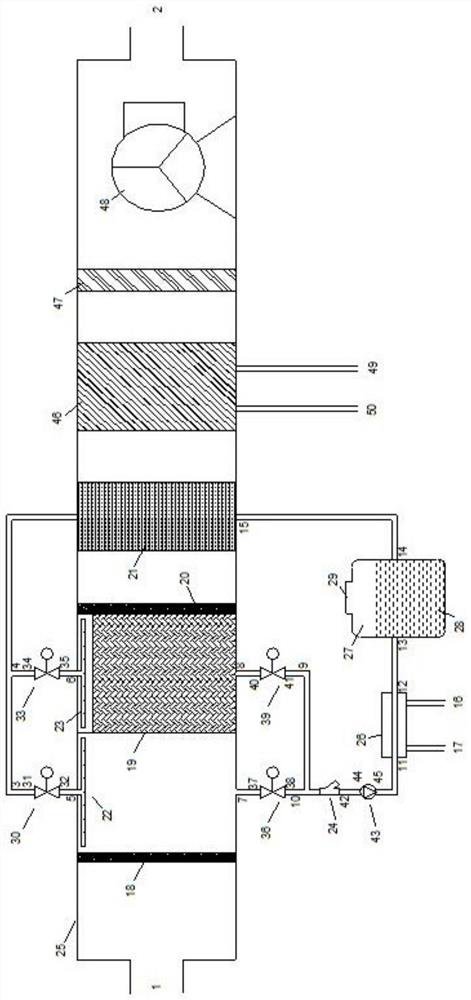

Breathing type building fresh air energy instant storage and exchange device

PendingCN114719372AReduce heat lossRealize heat recovery and utilizationMechanical apparatusLighting and heating apparatusAir changeFresh air

The invention discloses a breathing type building fresh air energy instant storage and exchange device which comprises an air exchange channel installed in a wall. The ventilation channel communicates indoor and outdoor; the ventilation channel comprises a fresh air flow channel and an exhaust flow channel which are mutually coupled; a fan is mounted on the inner side of the exhaust runner chamber; and the heat utilization unit is arranged in the ventilation channel and communicates the fresh air flow channel with the exhaust flow channel. The heat utilization unit is arranged in the wall body, so that the problem that a fresh air system in a building cannot well utilize heat and cold is solved; fresh air backheating can be achieved, heat loss is effectively reduced, heat energy recycling of indoor exhaust air is achieved, and building energy consumption is effectively reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Switchable equipment and process for producing white cement clinker and Portland cement clinker

ActiveCN112125539BRealize heat recovery and utilizationSolve the technical problem that it is difficult to effectively recover the heat of clinkerRotary drum furnacesMaintainance of heating chambersPortland cementExhaust fumes

The invention belongs to the field of cement firing process and equipment, and in particular relates to a switchable equipment and process for producing white cement clinker and Portland cement clinker. When producing white cement clinker, low-temperature secondary and tertiary air ducts are used for rotary Secondary and tertiary air are provided for fuel combustion in kilns and calciners. When producing Portland cement clinker, switch to high-temperature secondary and tertiary air pipes to provide high-temperature secondary and tertiary air for fuel combustion in rotary kilns and calciners, or use high-temperature tertiary air The pipeline provides high-temperature tertiary air for fuel combustion in the calciner, the secondary air enters the rotary kiln through the single-cylinder bleaching machine, and the residual air is discharged into the waste gas treatment system through the residual air pipeline. The invention provides a solution to the problem that the production process of white cement clinker and Portland cement clinker cannot be switched and compatible. Manufacturers can use equipment and devices that can switch between white cement clinker and Portland cement clinker according to market demand. Process, flexible choice to produce white cement clinker and Portland cement clinker.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

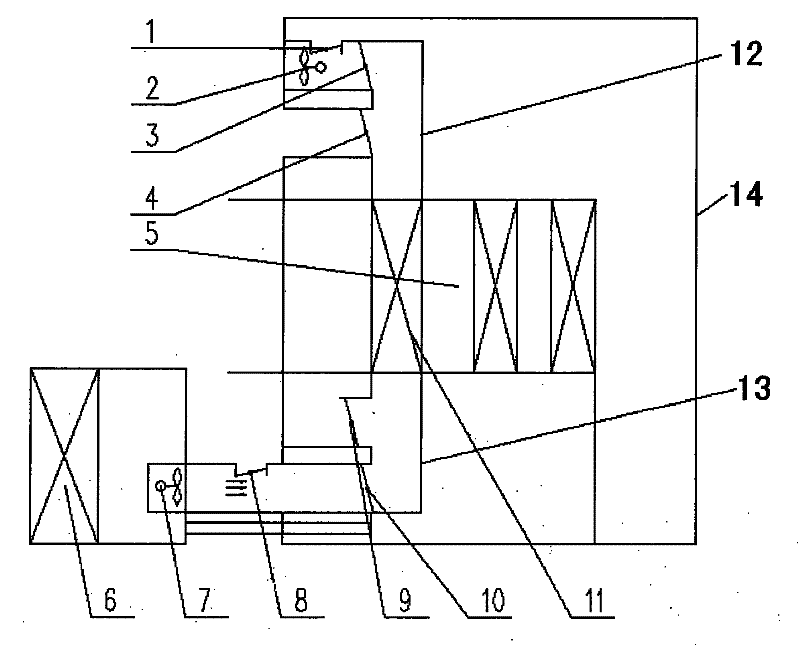

An air treatment device and method

ActiveCN106091133BAchieve dust removalRealize integrationMechanical apparatusLighting and heating apparatusThermodynamicsAir treatment

The invention discloses an air treatment device and method. Two circulations are carried out through the same solution to realize the organic combination of dehumidification, dust removal and reheating, and then the sensible heat in the air is processed through a surface cooler, so that the system has both solution dehumidification and dehumidification. With the advantages of energy saving and environmental protection, it can increase the inlet water temperature of the surface cooler and reduce the energy consumption of the system. The air treatment device includes a box body, a first water baffle, a second water baffle, a dehumidification device, a dust removal device, a finned coil, a surface cooler, a rectifying plate and a fan, and a connecting device arranged outside the box; The first water baffle and the second water baffle are fixedly connected on the inner wall of the box, and the first water baffle is close to the air input end of the box; the dehumidification device and the dust removal device are located on the first water baffle and the second water baffle Between; the finned coil, the surface cooler, the rectifying plate and the fan are arranged in sequence between the second water baffle and the air output end; the connecting device is respectively connected to the dehumidification device, the dust removal device and the finned coil to form a circulation loop.

Owner:NANJING TECH UNIV

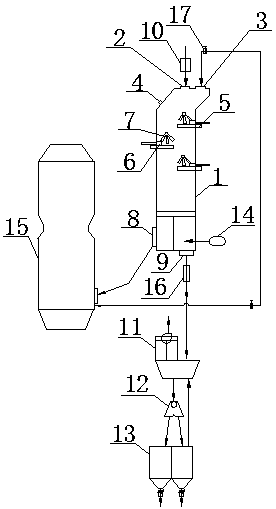

Heat recovery type full fresh air cooled dehumidifier

ActiveCN101907341BImprove cooling efficiencyReduce energy consumptionEnergy recovery in ventilation and heatingHeat recovery systemsFresh airEngineering

The invention provides a heat recovery type full fresh air cooled dehumidifier. In the dehumidifier, an indoor unit of the full fresh air cooled dehumidifier is arranged indoors, and is connected with a heat recovery heat exchanger; the top end of the heat recovery heat exchanger is connected to the outdoors through a first air pipe (i); the air outlet of the first air pipe (i) is provided with an exhaust fan; the side wall of the first air pipe (i) and an air pipe port which are close to the exhaust fan indoors are provided with a first air valve (i) and a second air valve (ii) respectively; a third air valve (iii) is arranged on the first air pipe (i) between the second air valve (ii) and the heat recovery heat exchanger; the third air valve (iii) is arranged outdoors; and the lower end of the heat recovery heat exchanger is connected with the draught fan of the outdoor unit of the full fresh air cooled dehumidifier through a second air pipe (ii). The dehumidifier has the beneficial effects of realizing high cooling efficiency, low energy consumption, stable operation and long service life of the full fresh air cooled dehumidifier, and realizing heat recycle.

Owner:TELLHOW SCI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com