Heat energy reutilization process of freezing filter unit

A filter unit and heat energy technology, applied in heat exchangers, heat exchanger types, indirect heat exchangers, etc., can solve the problems of heat energy loss, waste of resources, etc., and achieve the effect of heat energy recycling and scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

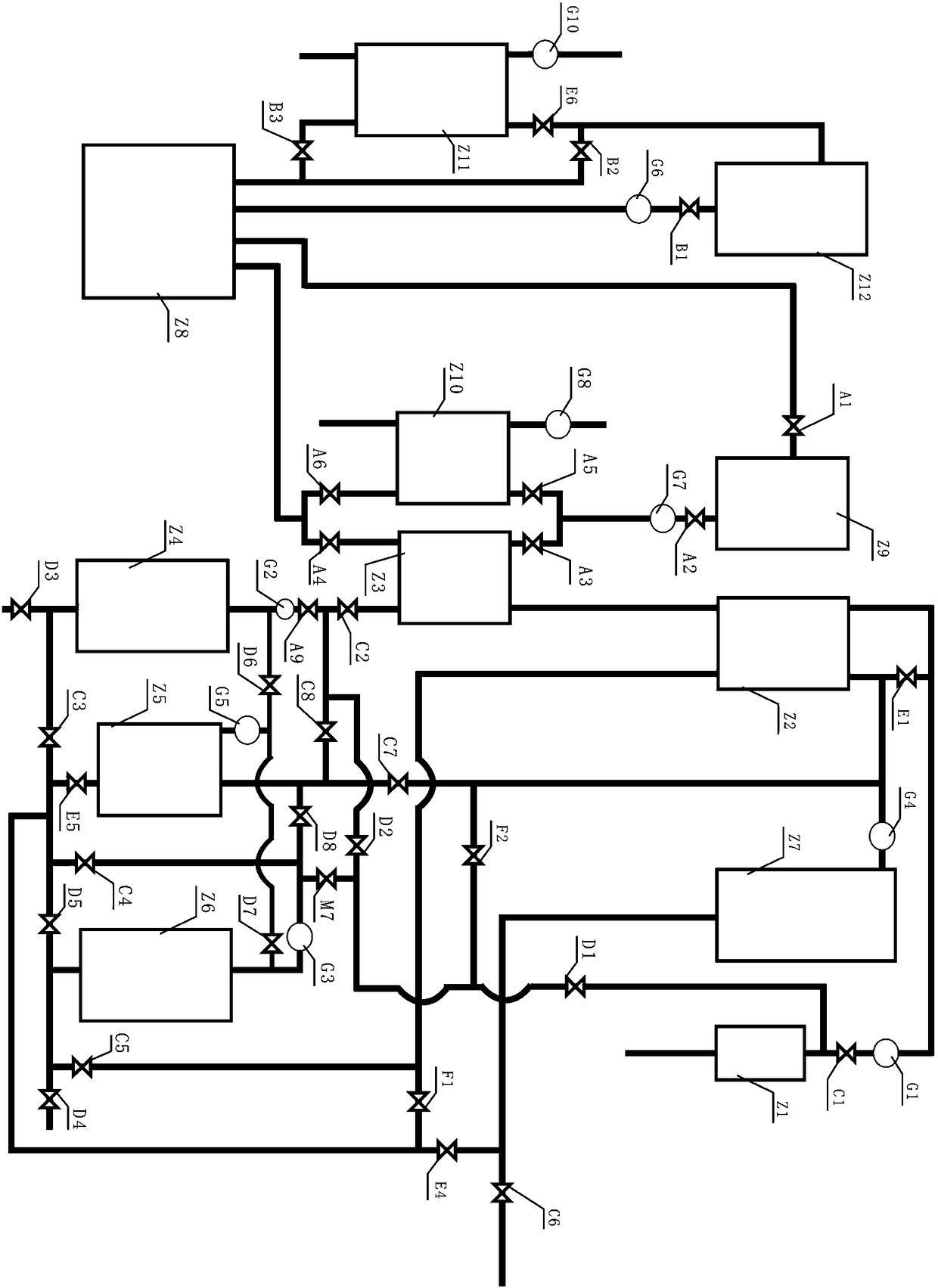

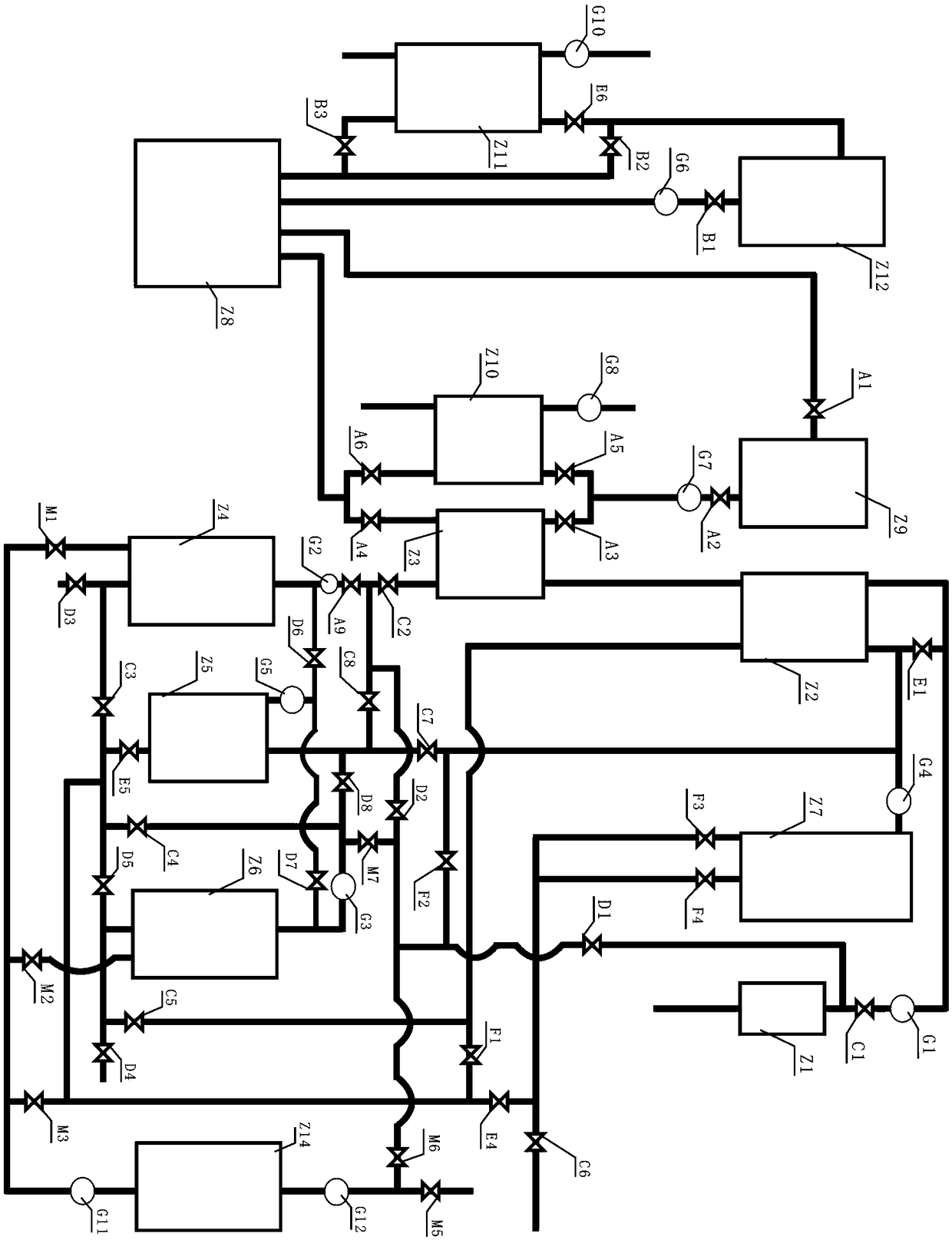

[0008] Method 1, refer to figure 1 , the process of the present invention provides a freeze filtration device, the device improves work efficiency, reduces production costs, and respectively realizes freeze filtration, normal temperature filtration, rapid cooling and heat energy recovery processes.

[0009] Said one kind of freezing and filtering device includes: Z8 refrigeration system, A cooling water circulation system, B cooling water circulation system, A refrigerant circulation system, B refrigerant circulation system, A cold inlet liquid system, B cold inlet liquid system, C cold inlet liquid System, A filter hanging soil system, B filter hanging soil system, C filter hanging soil system, A large cycle cooling system, B large cycle cooling system, C large cycle cooling system, A freeze filter system, B freeze filter system, C freeze Filtration system, D constant liquid inlet system, E constant liquid inlet system, F constant liquid inlet system, G constant liquid inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com