Mechanical grate type garbage gasification incinerator and its boiler power generation system

A technology for generating electricity from mechanical grates and boilers, which is applied in the direction of mechanical equipment, machines/engines, incinerators, etc. It can solve the problems of large supply, short ash cleaning maintenance cycle, and small waste disposal volume, so as to achieve the goal of increasing energy Utilization rate, improvement of energy conversion efficiency, effect of large amount of waste disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

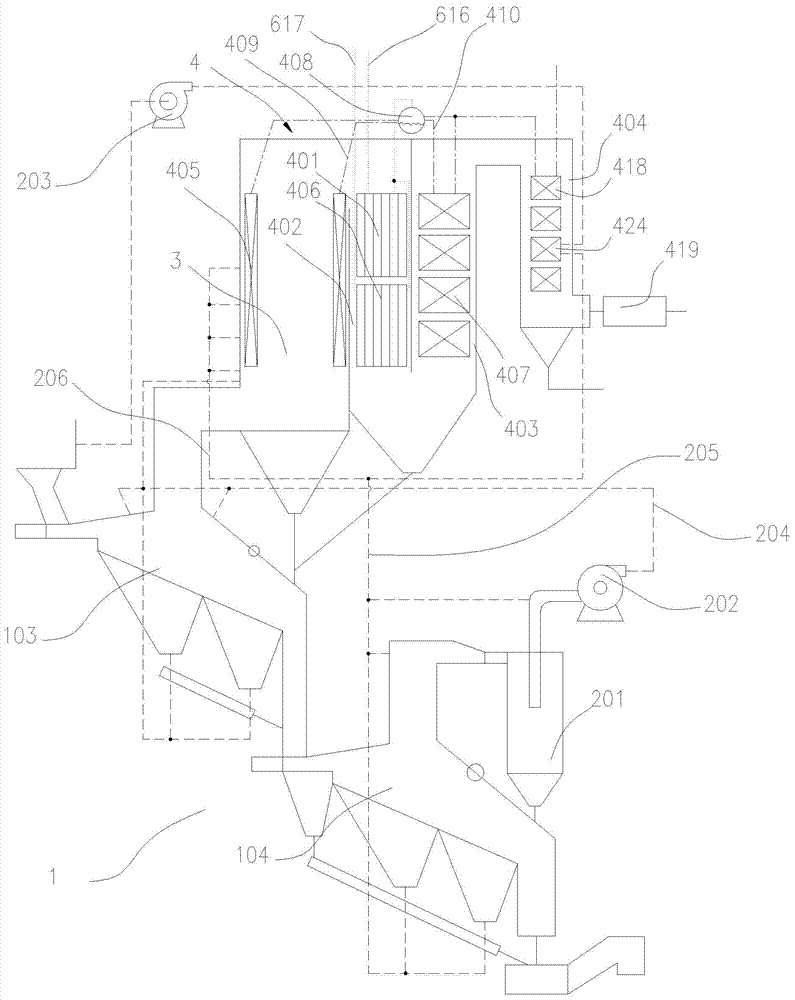

[0045] see Figure 1 to Figure 7 , is a preferred embodiment of a mechanical grate type garbage gasification incinerator and its boiler power generation system, including a gasification incinerator, a boiler system, a circulating air supply system, and a power generation system.

[0046] see Figure 4 The power generation system includes a steam turbine and a generator 613 power-connected with the steam turbine. The steam turbine includes a high-pressure cylinder 601, a medium-pressure cylinder 602, and a low-pressure cylinder 603. A first-stage water vapor is arranged between the high-pressure cylinder 601 and the medium-pressure cylinder 602. Separator 604, first-stage high-pressure steam heater 605, the input end of the first-stage water-steam separator 604 is connected to the output end of the high-pressure cylinder 601 through a pipeline, and the steam output end of the first-stage water-steam separator 604 is connected to the first-stage water-steam separator 604. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com