Device and method for disposing multiple kinds of waste synergistically in cement kiln

A technology for co-processing and waste, applied in the direction of combustion methods, waste heat treatment, lighting and heating equipment, etc., can solve problems such as insufficient incineration, prolonged incineration time, increased energy consumption, etc., to shorten incineration time, reduce disposal costs, The effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

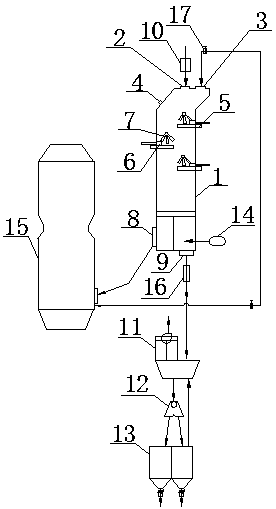

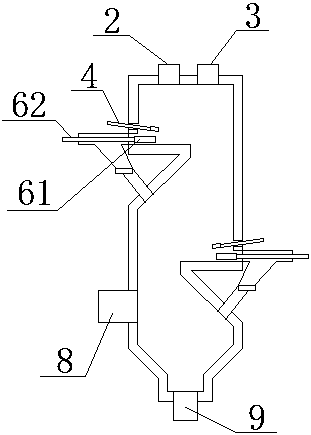

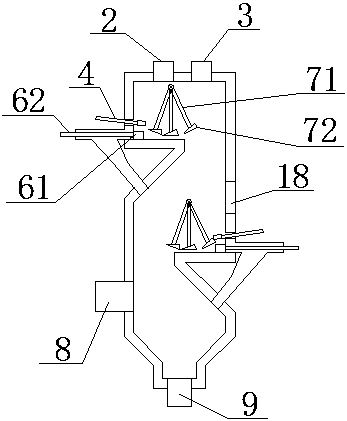

[0046] Such as figure 1 As shown, a device for co-processing various wastes in a cement kiln shown in a preferred embodiment of the present invention includes a furnace body 1, and a feed inlet 2 and an air inlet 3 are arranged on the top of the furnace body 1. The feed port 2 is used to add waste to be incinerated, mainly solid waste, and the air inlet 3 is used to introduce high-temperature hot air. The air inlet pipe is provided with a hot air valve 17 to realize switch control. The waste in the furnace body 1 is preheated. The bottom of the furnace body 1 is provided with a slag discharge port 9, which is used to discharge the residue generated after the waste is incinerated. The 2 feed ports are provided with a feed The air lock 10 and the feed air lock 10 belong to the existing structure in terms of the structure itself, but in the field of waste incineration, the air lock is not used. In this scheme, by using the feed air lock 10, it can Effectively prevent air channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com