Hot-melt-type solidification latent heat pump capable of recycling waste heat

A heat-melting, heat-heating technology, applied in fluid heaters, lighting and heating equipment, damage protection, etc., can solve the problems of abnormal operation, low work efficiency, high cost, etc., to ensure normal start-up and stable operation, Improve heating efficiency and facilitate maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

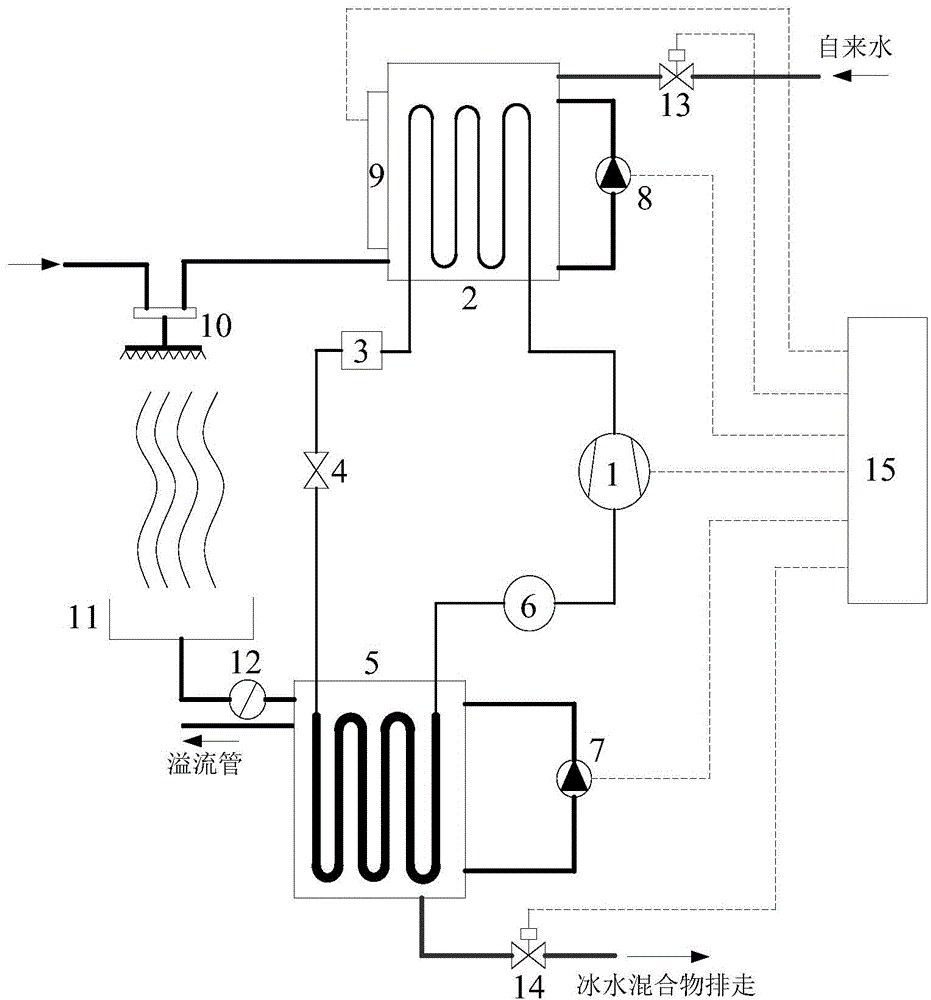

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0013] When realizing the present invention, compressor 1, condensation water tank 2, drier filter 3, throttling device 4, evaporation water tank 5, gas-liquid separator 6 are connected successively, and its working principle is basically the same as general water source heat pump; Tap water solenoid valve 13 Connected with the condensed water tank 2 through the tap water supply pipeline; the drain solenoid valve is connected with the evaporated water tank 5 through the drain pipe 14; the user heat utilization system 10 is connected with the condensed water tank 2 through the pipeline; The evaporation water tank 5 is connected sequentially through pipelines; the suction inlet and outlet of the evaporation water tank circulation pump 7 are connected with the evaporation water tank 5 through pipelines, and the suction inlet an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com