Switchable equipment and process for producing white cement clinker and Portland cement clinker

A Portland cement and white cement technology, applied in lighting and heating equipment, improvement of process efficiency, maintenance of heating chamber, etc., can solve the problem that white cement clinker and Portland cement clinker production process cannot be switched and compatible problem, to achieve the effect of high output, realization of heat recovery and utilization, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

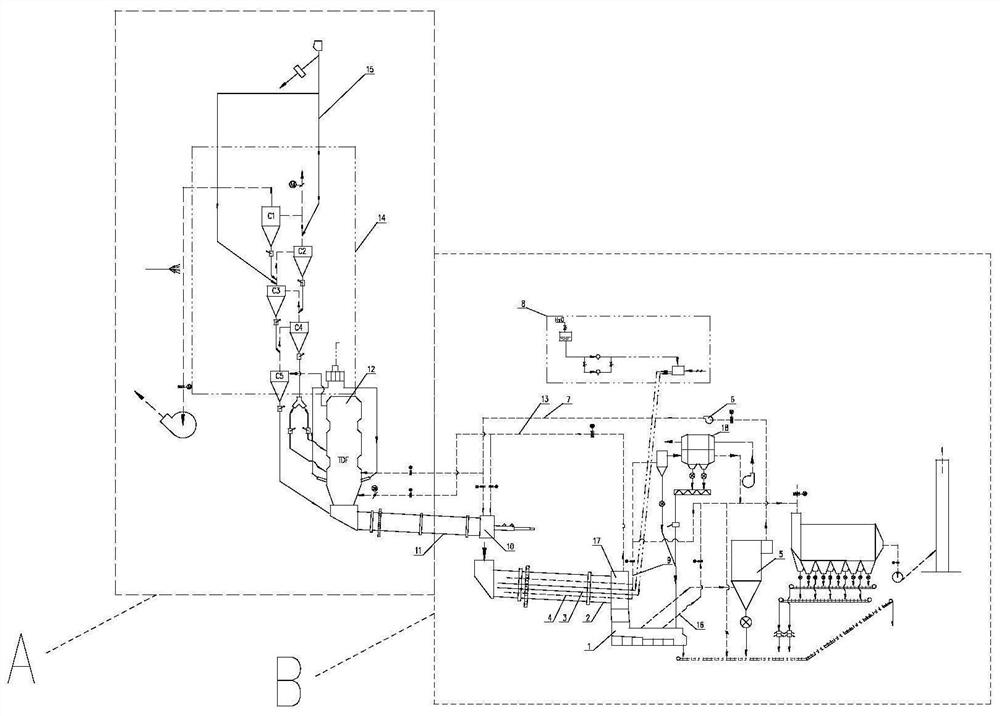

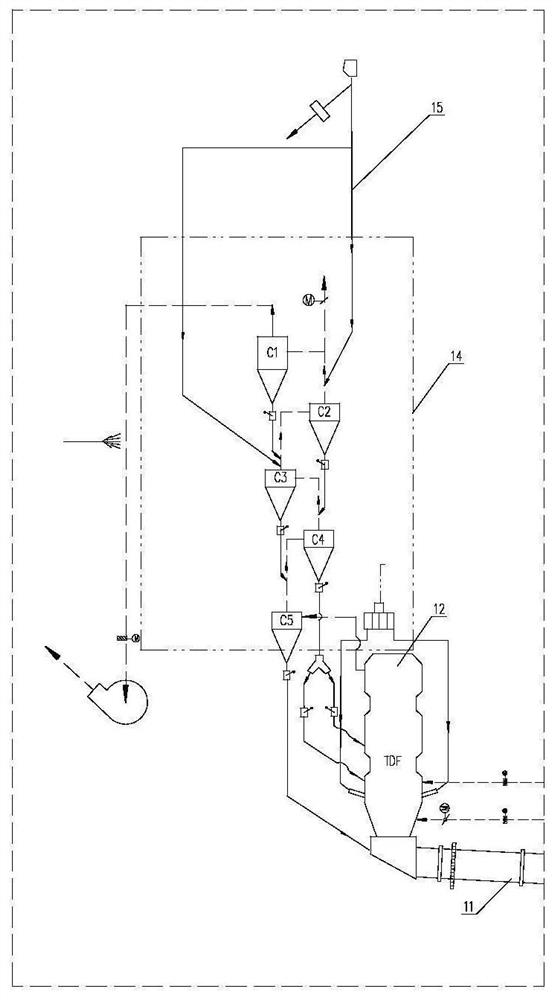

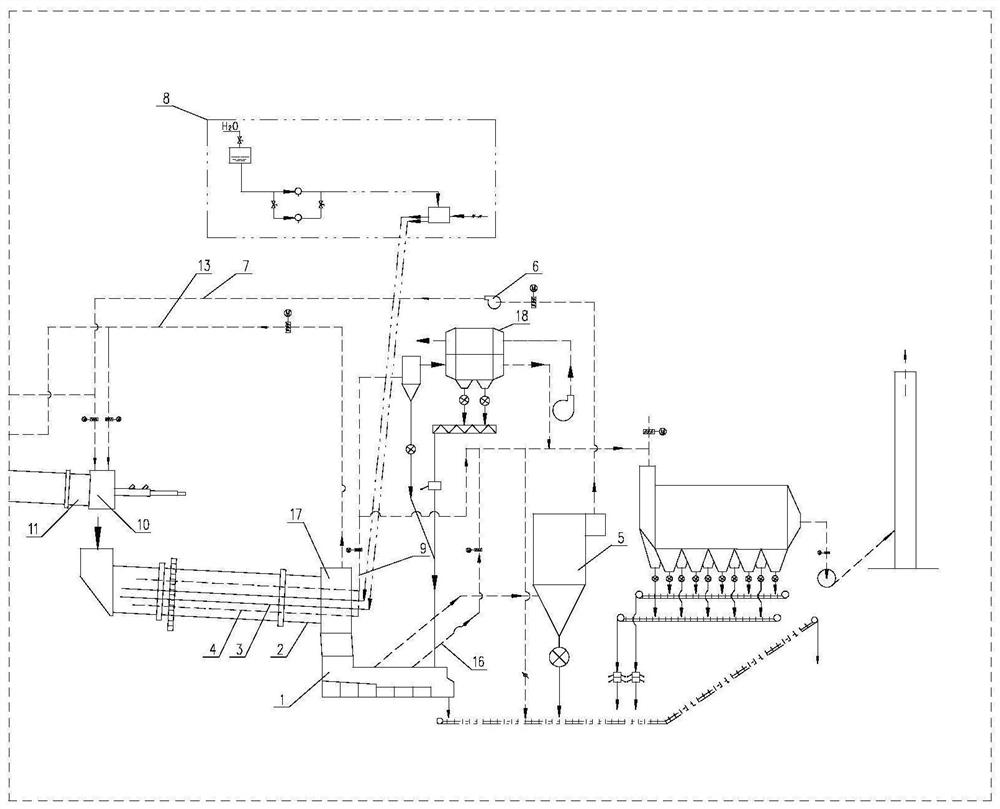

[0056] A switchable production of white cement clinker and Portland cement clinker, the switchable production of white cement clinker and Portland cement clinker includes: a preheater 14, the preheater 14 can be based on Requirements for moisture drying of raw materials specifically select the number of preheater stages, the preheating system is connected to the calciner 12, the calciner is connected to the rotary kiln 11, and the rotary kiln is connected to cooling equipment; the cooling equipment includes the unit The barrel bleaching machine 2 and the grate cooler 1 connected in series, the feed port of the single barrel bleaching machine 2 is connected with the rotary kiln door cover 10, the discharge port is connected with the feed port of the grate cooler 1, and the grate cooler The machine cools the clinker to below 100°C;

[0057] When producing white cement clinker, the grate cooler 1 is equipped with a hot air outlet, and the hot air outlet is respectively connected ...

Embodiment 2

[0071] A switchable process for producing white cement clinker, the switchable process for producing white cement clinker adopts equipment that can switch for producing white cement clinker and Portland cement clinker, and the switchable process for producing white cement clinker The material process includes the following steps:

[0072] Step 1: The raw material for producing white cement clinker is fed into the preheater system 14, and the white cement clinker is calcined through the calciner 12 and the rotary kiln 11;

[0073] Step 2: Enter the single-cylinder bleaching machine 2, spray water through the water spray pipe 3, spray water to quench the high-temperature white cement clinker leaving the kiln to 500-650°C, and exhaust the water vapor generated by the water spray through the exhaust pipe 4 to avoid water Steam enters the kiln to reduce the temperature of the flame in the firing zone, which affects the calcination of clinker;

[0074] Step 3: Air at normal tempera...

Embodiment 3

[0076] A switchable process for producing Portland cement clinker, the switchable process for producing Portland cement clinker adopts equipment that can switch for producing white cement clinker and Portland cement clinker, and the switchable The process of producing Portland cement clinker includes the following steps:

[0077] Step 1: before switching from the production of white cement clinker to portland cement clinker, the water spray pipe 3 and the exhaust pipe 4 need to be drawn out or protected from the single cylinder bleaching machine 2;

[0078]Step 2: The raw meal for producing Portland cement clinker is fed into the preheater system 14, and the Portland cement clinker is calcined through the calciner 12 and the rotary kiln 11;

[0079] Step 3: Quickly pass through the single-cylinder bleaching machine 2, keep the high-temperature clinker leaving the kiln at a temperature of 1300-1400°C, enter the grate cooler 1 and cool it to below 100°C, and at the same time pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com