Combined cooling, heating and power supply system based on gradient utilization and deep recovery of waste heat

A combined cooling, heating and power supply, cascade technology, applied in engine components, machines/engines, internal combustion piston engines, etc., can solve the problem of waste heat being unable to be effectively utilized and cannot be further recovered, and achieve the effect of reducing waste and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

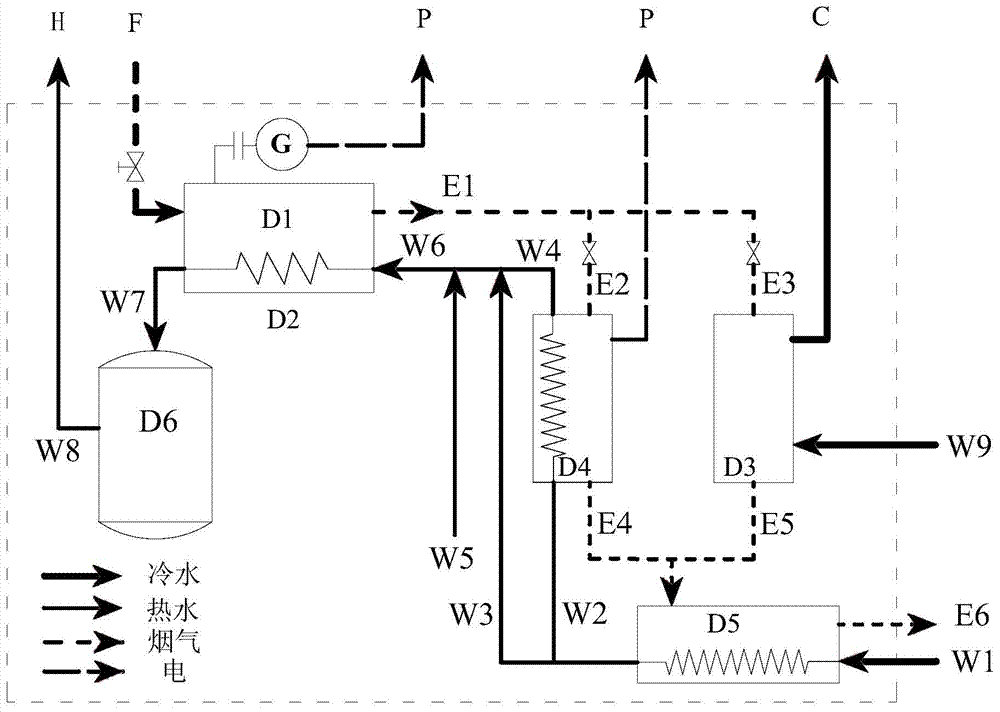

[0033] like figure 1 As shown, a combined cooling, heating and power system based on waste heat cascade utilization and deep recovery, including internal combustion engine D1, jacket water heat exchanger D2, flue gas type double-effect lithium bromide absorption heat pump D3, thermoelectric power generation device D4, flue gas Condensing heat exchanger D5 and hot water tank D6.

[0034] Internal gas D1 is gas internal gas, which is used to directly drive the generating set to generate electricity. The gas-fired internal combustion engine is equipped with a jacket water heat exchanger D2 on the basis of the original jacket water circulation. The flue gas outlet of the gas internal combustion engine is divided into a first flue gas pipeline and a second flue gas pipeline, the first flue gas pipeline is connected with the thermoelectric power generation device D4, and the flue gas in the first flue gas pipeline is used for To drive the thermoelectric power generation device D4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com