Economizer capable of recycling waste heat of flue in depth and concealing, desulfurizing and aspirating flue of coal-fired boiler

A flue gas waste heat, coal-fired boiler technology, applied in feed water heaters, preheating, heat exchange equipment, etc., can solve the problems of large exhaust heat loss and high exhaust temperature, and achieve boiler efficiency improvement, load reduction and operation. cost, and the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

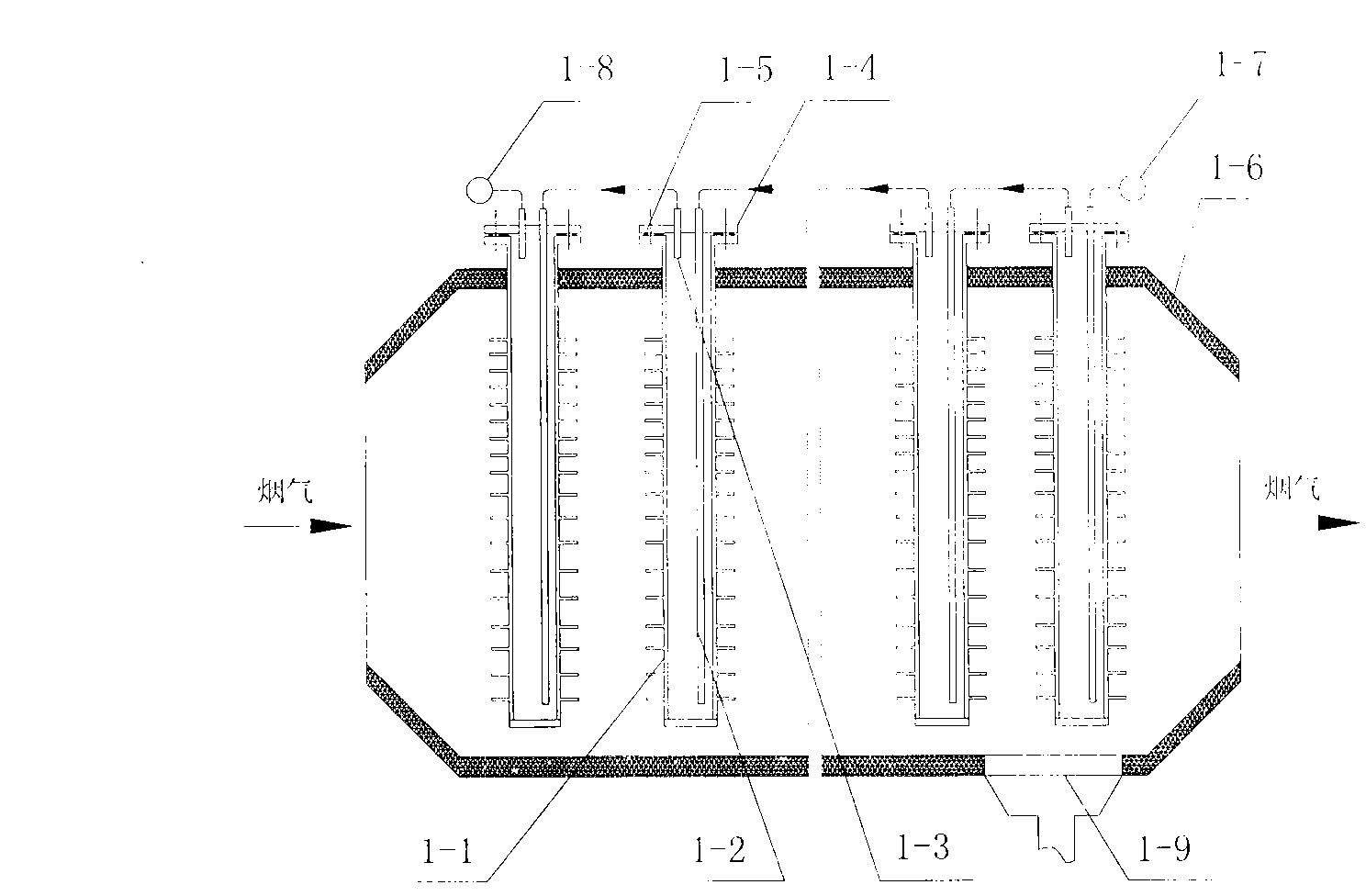

[0024] figure 1 It is a schematic diagram of the structure of the economizer proposed by the present invention. The economizer proposed by the present invention is mainly composed of a heat exchange tube 1-1, a shell 1-6, a water inlet header 1-7, a water outlet header 1-8 and a condensate collection port 1-9. The heat exchange tube 1-1 is a round finned tube made of graphite material. The lower end of the heat exchange tube 1-1 is a closed structure, and the upper end is a ferrule structure. The sealing ring 1-5 is used to make the heat exchange tube 1-1 and The metal parts 1-4 are connected, the metal parts 1-4 are provided with a low temperature water inlet 1-2 and a high temperature water outlet 1-3, and the tube of the low temperature water inlet 1-2 is inserted into the bottom of the heat exchange tube 1-1. The rows of heat exchange tubes are connected in series and installed horizontally, and the rows of heat exchange tubes are arranged in a staggered arrangement. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com