Energy-saving type thermal power plant flue gas moisture recovering system

A recycling system, a technology for thermal power plants, applied in energy-saving heating/cooling, energy industry, climate change adaptation, etc., can solve the problem of low temperature of circulating water for cooling, and achieve the effect of reducing energy consumption and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

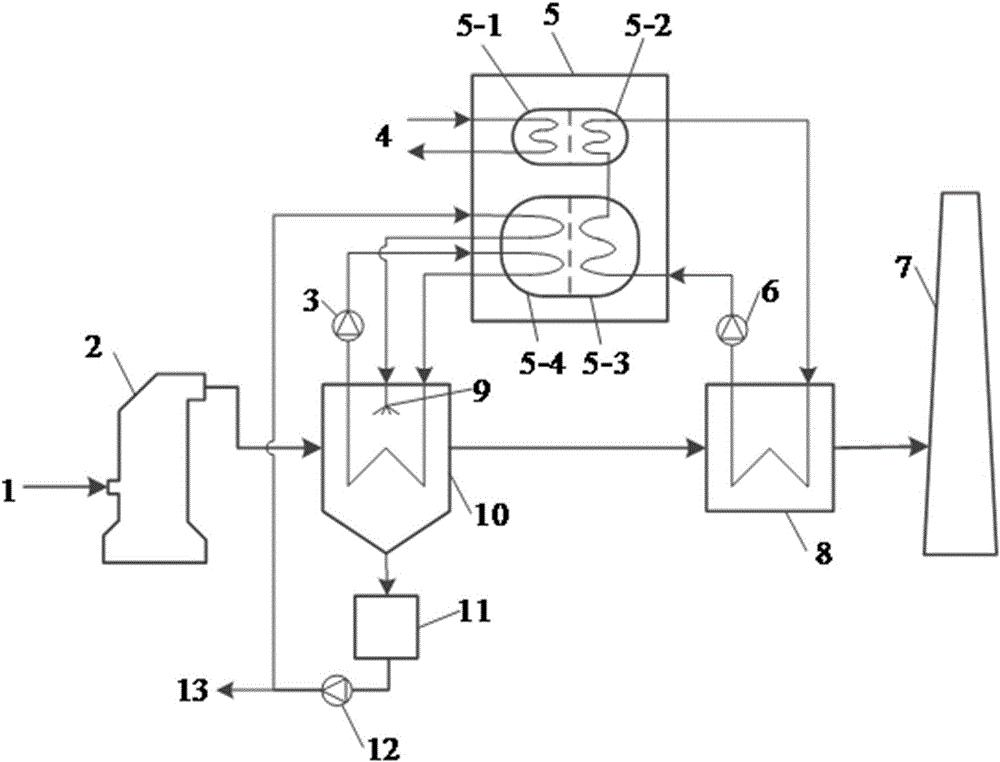

[0026] In this embodiment, the structure of the present invention is described in detail with reference to the drawings.

[0027] Please refer to the accompanying drawings, an energy-saving thermal power plant flue gas moisture recovery system, the system includes a sequentially connected wet desulfurization tower 2, a flue gas condensation system 10, a flue gas reheater 8, and a chimney 7. While the flue gas condenser condenses the moisture in the flue gas, the heat pump 5 transfers the waste heat in the flue gas to the heat medium water of the flue gas reheater 8 through the cooling pipe row and spray water, which is used for the flue gas reheater The heating of the heat medium water increases the temperature of the flue gas and realizes the discharge of dry flue gas.

[0028] The flue gas condensation system includes the following:

[0029] Flue gas condenser 10, a device for cooling and condensing flue gas, including internal heat exchange tube bundles (composite material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com