Low temperature flue gas waste heat utilization, desulphurization, denitration and white smoke elimination integrated system of industrial furnace

A low-temperature flue gas, industrial furnace technology, applied in the direction of reducing greenhouse gas, furnace, waste heat treatment, etc., can solve the problems of high pollutant emission concentration, large pollutant emission, serious environmental pollution, etc., to save investment and reduce occupation. Floor area, the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

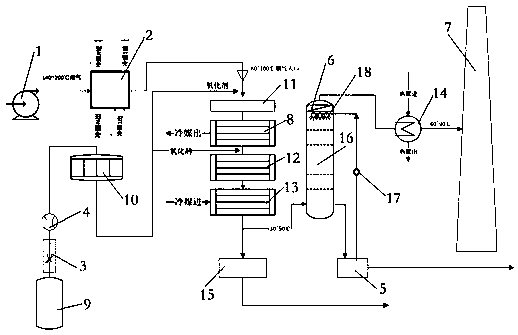

Embodiment 1

[0042] like figure 1 As shown, it also includes an oxidant system 9, an oxidant activator 10, a denitration catalyst 11, a second flue gas condensation and denitration reactor 12, a third flue gas condensation and denitration reactor 13, and a flue gas warmer 14. The oxidant system 9 is set corresponding to the flow regulating valve 3, and the flow meter 4 is respectively connected to the outlet of the flue gas channel of the multi-strand refrigerant heat exchange system 2 and the flue gas channel outlet of the first flue gas condensation and denitrification reactor 8 through the oxidant activator 10 Correspondingly, the denitration catalyst 11 is arranged at the entrance of the flue gas channel of the first flue gas condensation and denitration reactor 8, the first flue gas condensation and denitration reactor 8, the second flue gas condensation and denitration reaction The device 12 and the third flue gas condensation and denitrification reactor 13 are arranged corresponding...

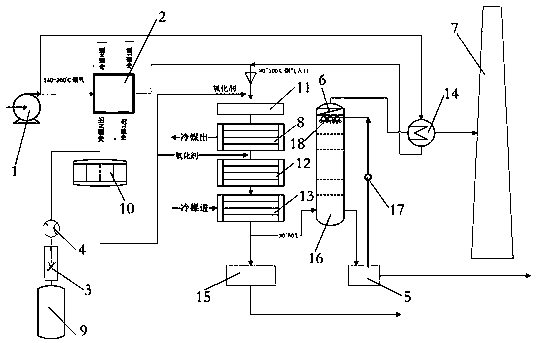

Embodiment 2

[0044] like figure 2 As shown, it also includes an oxidant system 9, an oxidant activator 10, a denitration catalyst 11, a second flue gas condensation and denitration reactor 12, a third flue gas condensation and denitration reactor 13, and a flue gas warmer 14. The oxidant system 9 is set corresponding to the flow regulating valve 3, and the flow meter 4 is respectively connected to the outlet of the flue gas channel of the multi-strand refrigerant heat exchange system 2 and the flue gas channel outlet of the first flue gas condensation and denitrification reactor 8 through the oxidant activator 10 Correspondingly, the denitration catalyst 11 is arranged at the entrance of the flue gas channel of the first flue gas condensation and denitration reactor 8, the first flue gas condensation and denitration reactor 8, the second flue gas condensation and denitration reaction The device 12 and the third flue gas condensation and denitrification reactor 13 are arranged correspondin...

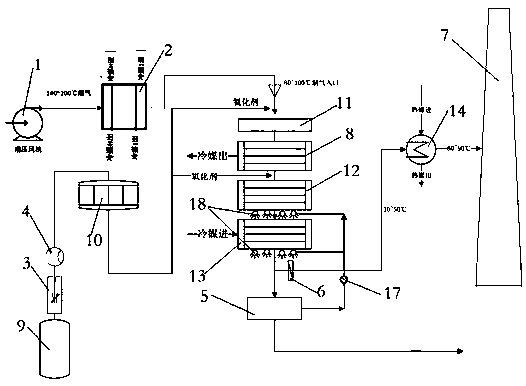

Embodiment 3

[0046] like image 3 As shown, it also includes an oxidant system 9, an oxidant activator 10, a denitration catalyst 11, a second flue gas condensation and denitration reactor 12, a third flue gas condensation and denitration reactor 13, and a flue gas warmer 14. The oxidant system 9 is set corresponding to the flow regulating valve 3, and the flow meter 4 is respectively connected to the outlet of the flue gas channel of the multi-strand refrigerant heat exchange system 2 and the flue gas channel outlet of the first flue gas condensation and denitrification reactor 8 through the oxidant activator 10 Correspondingly, the denitration catalyst 11 is arranged at the entrance of the flue gas channel of the first flue gas condensation and denitration reactor 8, the first flue gas condensation and denitration reactor 8, the second flue gas condensation and denitration reaction The device 12 and the third flue gas condensation and denitrification reactor 13 are arranged corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com