Oxygen manual stop valve safe operation method and tool

A manual shut-off valve, safe operation technology, applied in the valve operation/release device, manufacturing tool, wrench and other directions, can solve the problems of inconvenience and flexibility, cost increase, uneconomical valve field operation, etc., to achieve high safety and economical cost, and the effect of promoting implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

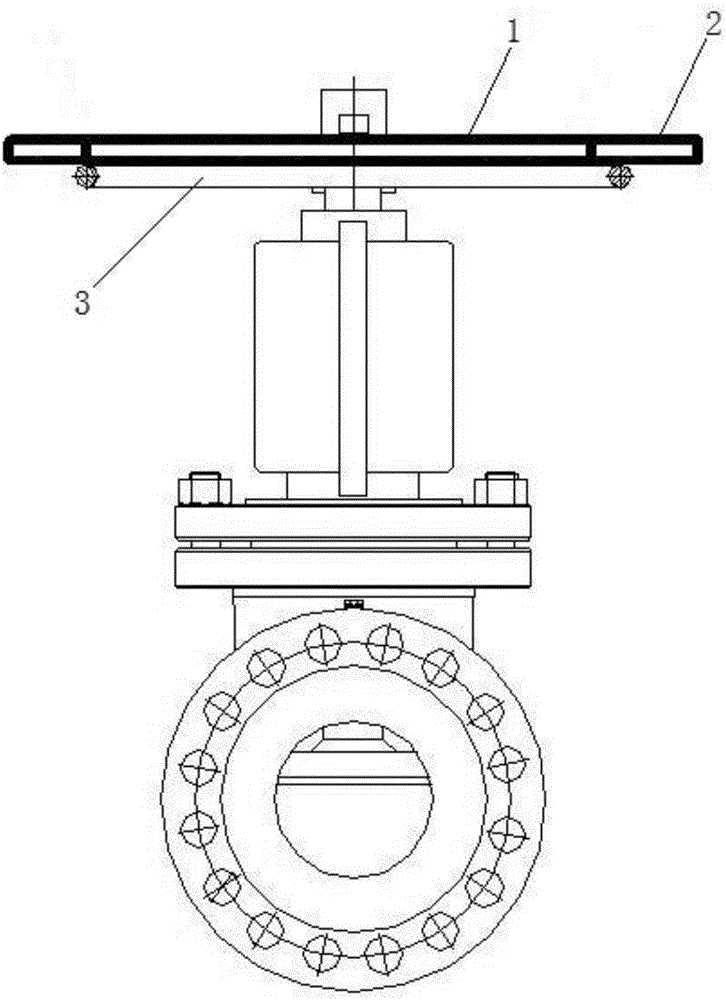

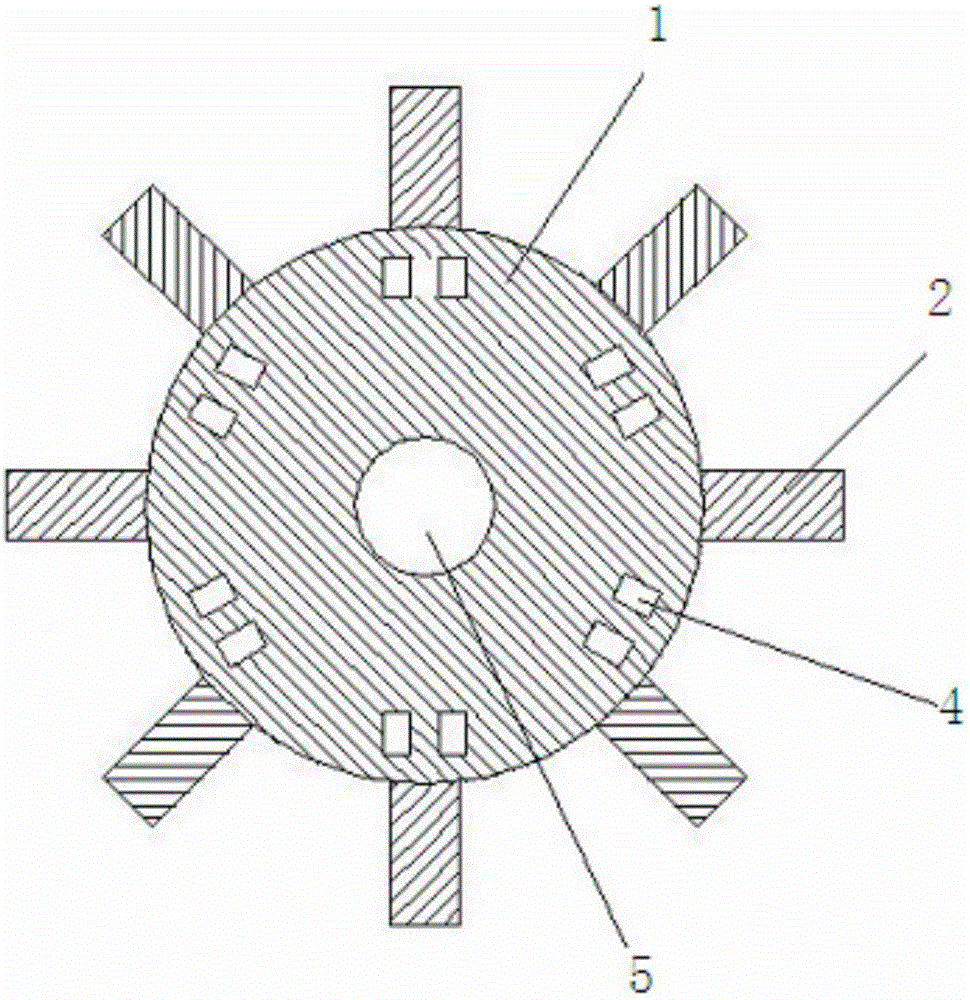

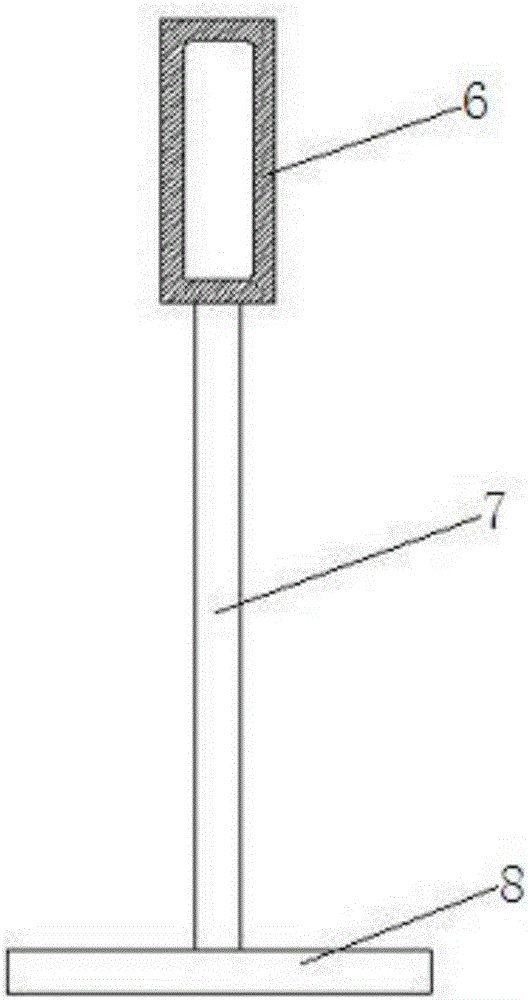

[0023] A method for safe operation of an oxygen manual shut-off valve, such as figure 1 As shown, before operation, the disc 1 is fixed on the hand wheel 3 of the oxygen manual shut-off valve, and the outer edge of the disc 1 is provided with a ring of protruding teeth 2, and the outermost end of the protruding teeth 2 protrudes from the outer edge of the hand wheel 3; during operation, operate The personnel hold the hand-held end of the operating rod 7 outside the explosion-proof wall and extend the operating end of the operating rod 7 to the oxygen manual shut-off valve inside the explosion-proof wall, such as image 3 As shown, the operating end of the operating rod 7 is a collar 6. The opening of the collar 6 can accommodate the protruding teeth 2 and is arranged on the side of the operating rod 7. Put the collar 6 on the protruding teeth 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com