Water purification viscosity reducer and preparation method thereof

A viscosity reducer and water purification technology, which is applied in the direction of chemical instruments and methods, water pollutants, natural water treatment, etc., can solve the problems of high treatment cost, high viscosity, poor feasibility, etc., and achieve good and obvious effect of viscosity reduction , solve complicated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

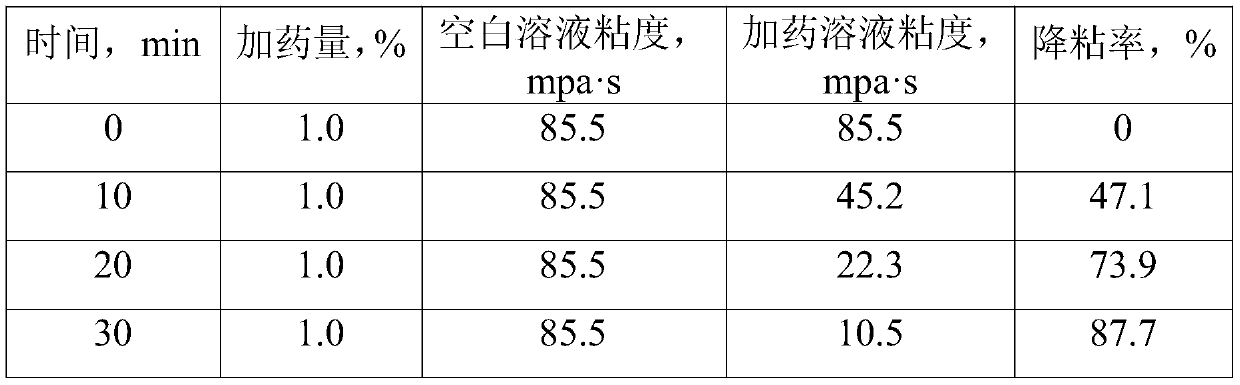

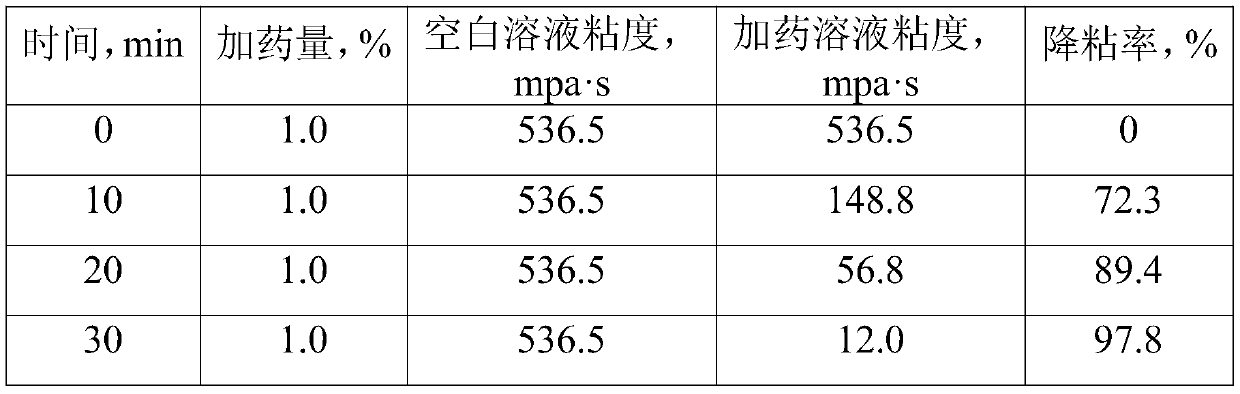

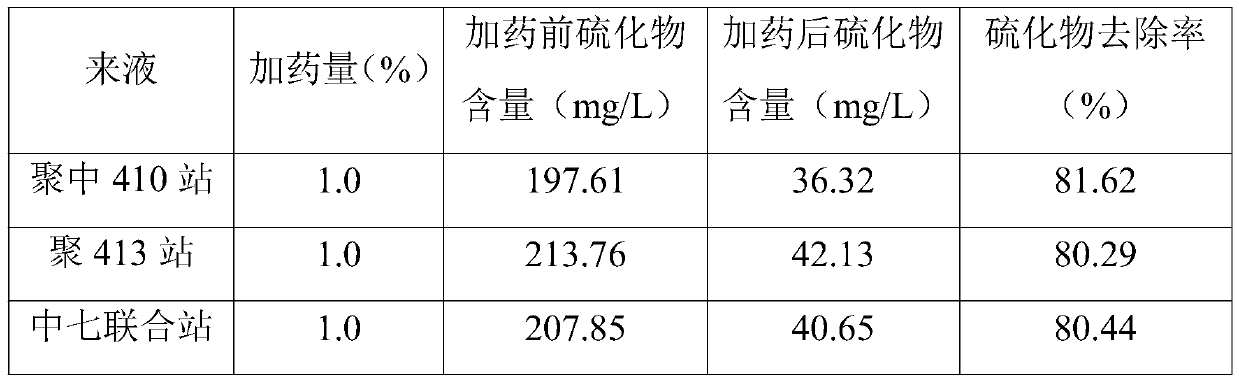

Examples

Embodiment 1

[0015] A preparation method of water purification and viscosity reducing agent, the specific operation method is as follows:

[0016] Put 100 parts of tap water into the reactor, start stirring, the speed is 300r / min, heat up to 30℃, put in 50 parts of polyallyl hydroxyethyl diethyl ammonium chloride (molecular weight 3000Da), stir for 2h Evenly, add 30 parts of octadecyl trimethyl ammonium chloride, the speed of rotation is 500r / min, fully stir for 30min, increase the speed to 1000r / min, add 10-part of ammonium persulfate, and fully stir for 30min to obtain Water purification viscosity reducer.

Embodiment 2

[0018] A preparation method of water purification and viscosity reducing agent, the specific operation method is as follows:

[0019] Put 300 parts of tap water into the reactor, turn on the stirring, the speed is 300r / min, heat up to 40℃, put in 100 parts of polyallyl hydroxyethyl diethyl ammonium chloride (molecular weight 9000Da), stir for 5h Evenly, add 50 parts of octadecyl trimethyl ammonium chloride, the speed of rotation is 500r / min, fully stir for 30min, increase the speed to 1000r / min, add 30 parts of ammonium persulfate, fully stir for 30min, the net is obtained Water viscosity reducer.

Embodiment 3

[0021] A preparation method of water purification and viscosity reducing agent, the specific operation method is as follows:

[0022] Put 200 parts of tap water into the reactor, start stirring, the speed is 300r / min, heat up to 35℃, put in 80 parts of polyallyl hydroxyethyl diethyl ammonium chloride (molecular weight 6000Da), stir for 3h Evenly, add 40 parts of octadecyl trimethyl ammonium chloride, the speed of rotation is 500r / min, fully stir for 30min, increase the speed to 1000r / min, add 20 parts of ammonium persulfate, fully stir for 30min, and make the net Water viscosity reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com