Clean-up Pneumatic Tank Sampler

A sampler and pneumatic technology, which is applied in the field of tank cleaning-free pneumatic under-tank samplers, can solve the problems such as the inability to directly observe the height of the sampling position in the tank, the large sampling error of the sampling position, waste of financial and material resources, etc., to avoid oil Product pollution and waste, easy operation, variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

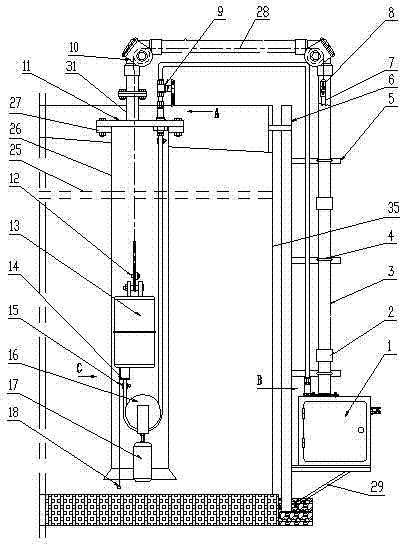

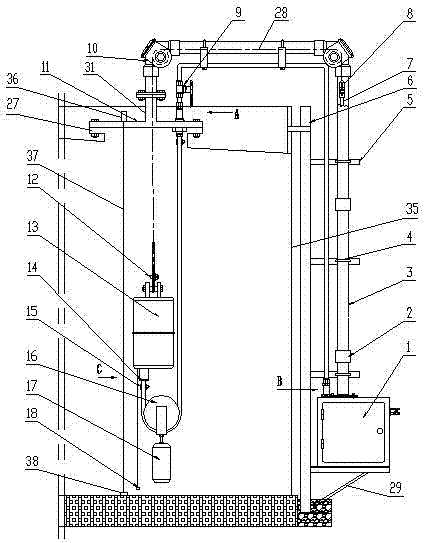

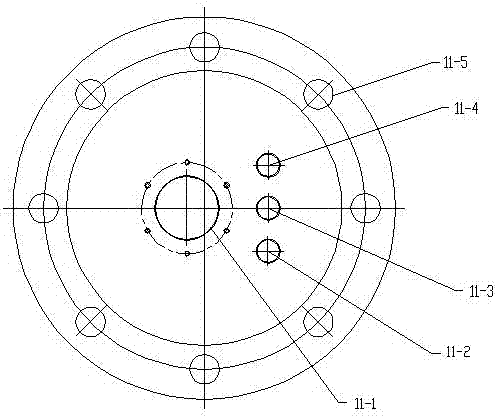

[0041] Such as Figure 1-22 As shown, the tank-free pneumatic type under-tank sampler is composed of an outer part and an inner part of the tank. Connecting flange 11, exhaust valve 30, protection pipe joint 31, intake pipe joint 32, oil outlet pipe joint 33, oil return pipe joint 34, column 6, operation box bracket 29, several support frames 5, operation box part installation 1, protection Pipeline, several U-shaped clips 4, scale code belt 7, steel wire rope 28 and cross connector 8, the oil pipeline outside the tank is composed of intake pipeline 19, oil outlet pipeline 20 with emergency ball valve 9 installed at the upper mouth end, and oil return pipeline 21, the connecting flange 11 is equipped with an exhaust valve 30, and is provided with a protective pipeline installation hole 11-1, an intake pipeline installation hole 11-2, an oil outlet pipeline installation hole 11-3, and an oil return pipeline installation hole 11-4 and several bolt holes 11-5, at the protection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com