Boiler flue gas white smoke removal system

A boiler flue gas and flue gas technology, applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problem of uneven heating of flue gas, achieve uniform and stable heat distribution, uniform heating, and prevent local white smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

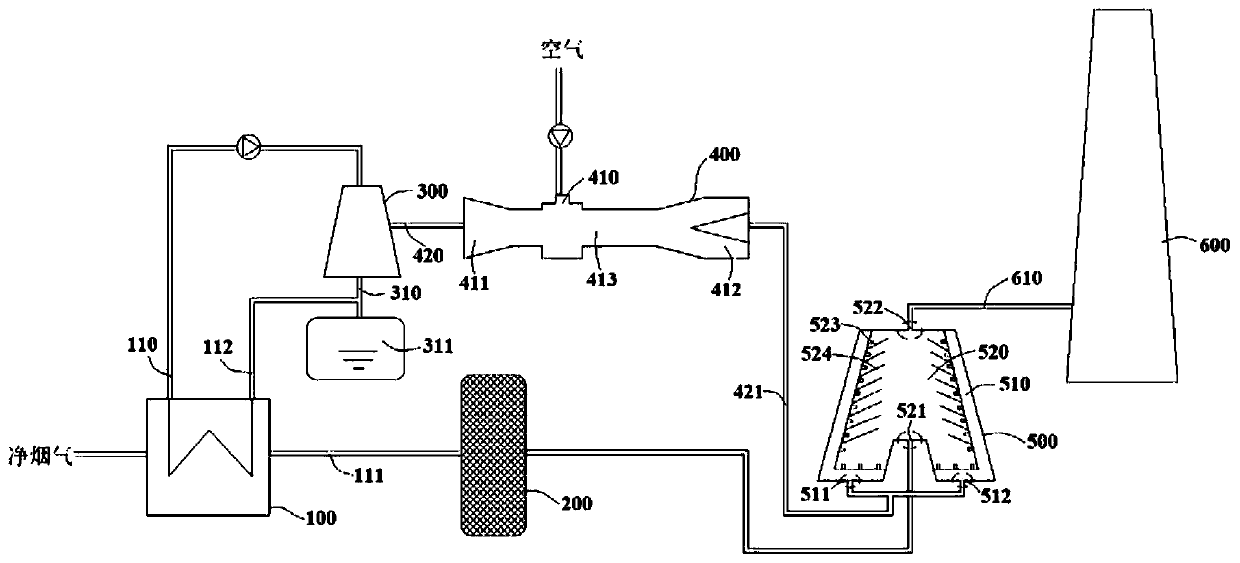

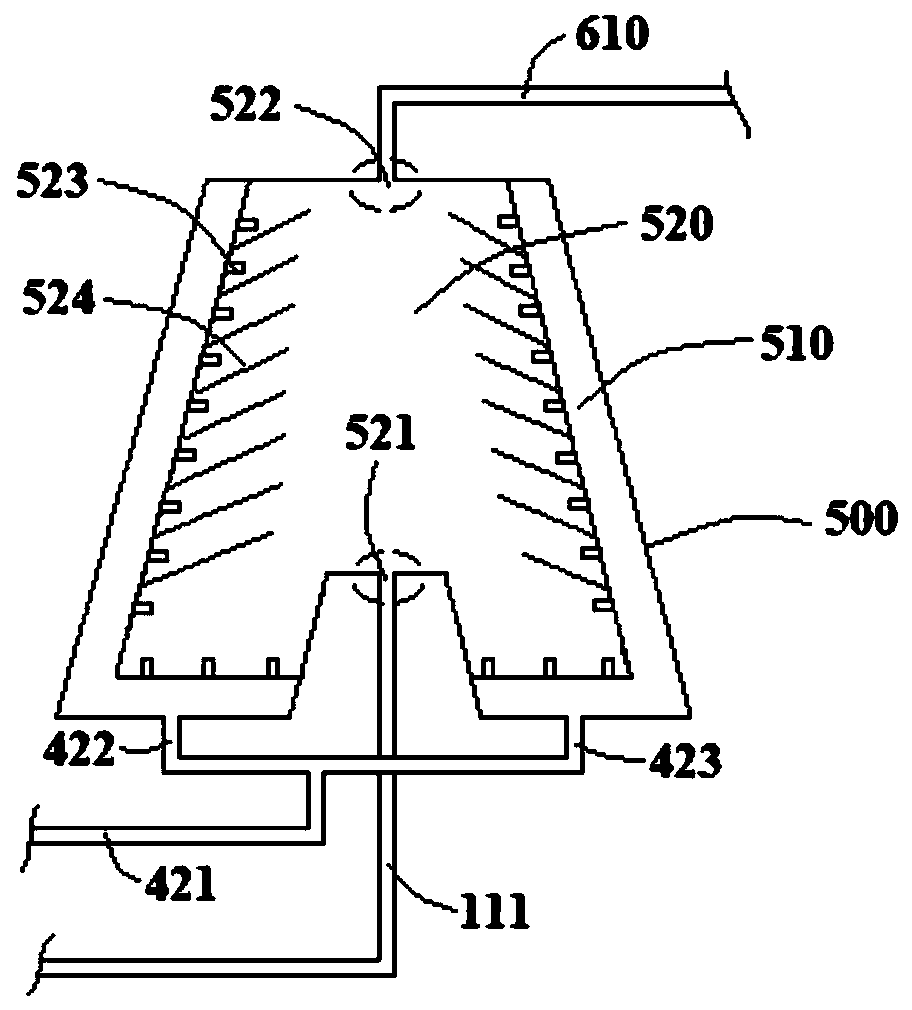

[0042] combine figure 1 and figure 2 , a boiler flue gas dewhitening system in this embodiment includes a flue gas condenser 100, a cooling tower 300, a vortex tube 400, and a flue gas heater 500 connected in sequence, and the vortex tube 400 is used to separate hot and cold air streams, which generate The cold air flow is used in the cooling tower 300 to cool down the circulating water. The flue gas heater 500 has a double-layer structure, which includes an outer splitting chamber 510 and an inner mixing chamber 520. The flue gas condensed by the flue gas condenser 100 It passes into the mixing chamber 520, and the mixing chamber 520 communicates with the flow diversion chamber 510 through the flow guide tube 523 arranged on its surface. The hot gas flow generated by the vortex tube 400 flows into the flow distribution chamber 510 and enters the mixing chamber 520 along the flow guide tube 523 to realize the integration with the flue gas. mixed heat transfer.

[0043] In t...

Embodiment 2

[0048] A boiler flue gas de-whitening system in this embodiment, its structure is basically the same as that in Embodiment 1. Further, the bottom wall of the diversion chamber 510 includes end horizontal sections 530 at both ends and a central middle protruding section 531, the middle protruding The section 531 is provided with a flue gas inlet 521 communicating with the mixing chamber 520 , and the end horizontal section 530 is provided with an air inlet communicating with the splitting chamber 510 . Preferably, the ratio of the height of the middle extension section 531 to the height of the flue gas heater 500 in this embodiment is 1 / 6˜1 / 4.

[0049] In order to promote the uniform mixing of flue gas and hot air flow, in this embodiment, the bottom wall of the distribution chamber 510 is arranged in a three-section structure, wherein the middle middle extension section 531 is protruded, and the flue gas inlet 521 is arranged on the middle extension section 531, so as to send ...

Embodiment 3

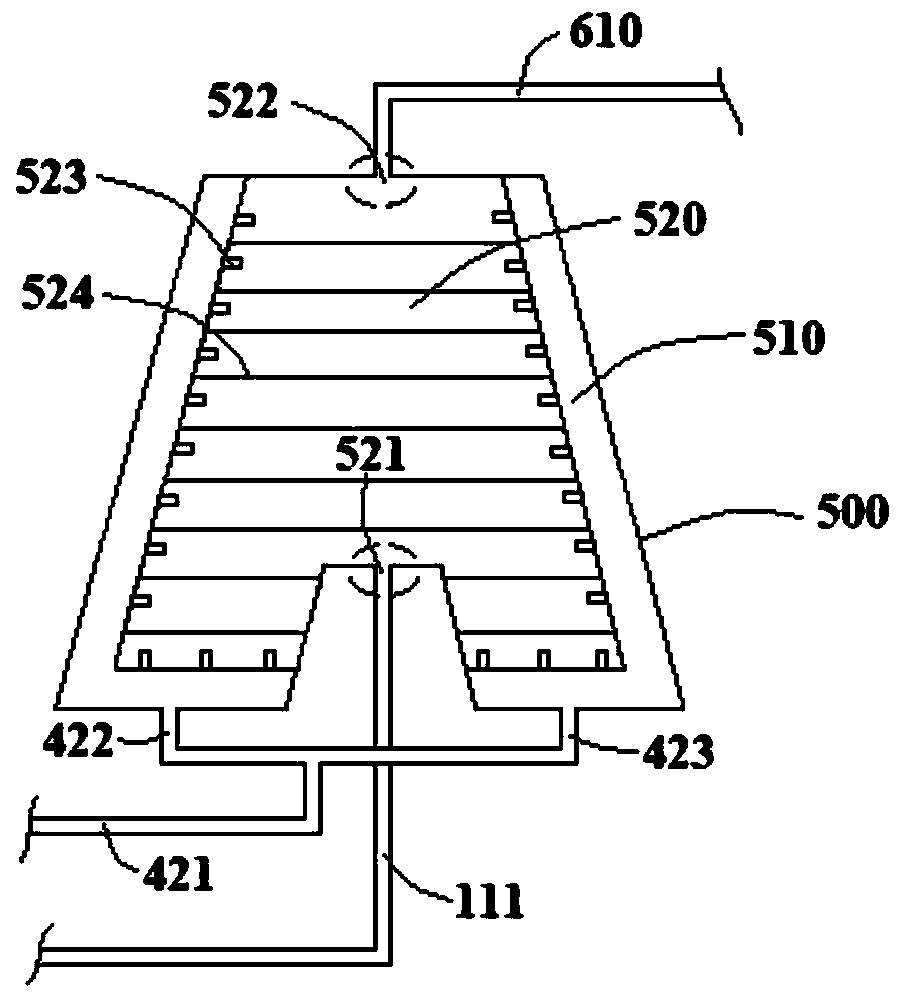

[0053] combine image 3 , a boiler flue gas dewhitening system in this embodiment, its structure is basically the same as in Embodiment 2, further, a flue gas baffle 524 is horizontally arranged on the side wall of the mixing chamber 520 in this embodiment, and the flue gas baffle 524 is provided with guide holes 525, and the flue gas baffles 524 and guide pipes 523 are arranged alternately. The flue gas baffle 524 in this embodiment communicates with the inner side wall of the mixing chamber 520, and a guide hole 525 is opened on the flue gas baffle 524, which can disperse the flue gas and further promote the mixing and uniform heating of the flue gas by the hot air flow .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com