Boiler flue gas pollution discharge and waste heat recovery heat pump heating system and application method thereof

A technology of waste heat recovery and flue gas waste heat, applied in the energy field, can solve the problems of inconvenient maintenance and cleaning of boiler flue gas waste heat recovery device, influence of boiler combustion conditions, heat waste of sewage, etc., to reduce the "greenhouse" effect, simple and reasonable structure, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

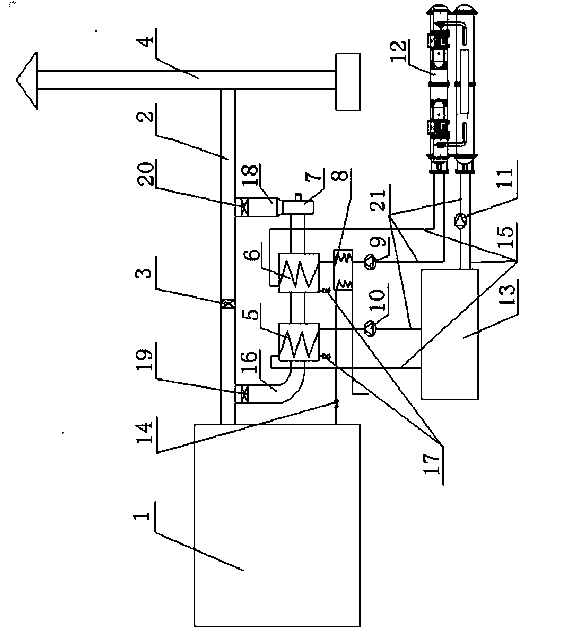

[0022] refer to figure 1 , the boiler flue gas waste heat recovery heat pump heating system and its use method in this embodiment, the boiler flue gas waste heat recovery heat pump heating system, the boiler is a gas boiler 1, which includes a main flue 2, a chimney 4, a flue gas waste heat Recycler, hot water tank 13 and high temperature heat pump unit 12, one end of the main flue 2 communicates with the gas boiler 1, and the other end communicates with the chimney 4, the main flue 2 is also provided with a bypass flue, the main flue 2 It communicates with the flue gas waste heat recovery device through the bypass flue; the bypass flue includes a bypass smoke inlet flue 16 and a bypass smoke outlet flue 18, and the flue gas waste heat recovery device includes a first-stage flue gas waste heat recovery device 5 and secondary flue gas waste heat recovery device 6, the lower parts of the primary flue gas waste heat recovery device 5 and the secondary flue gas waste heat recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com